White spirit production process

A production process and liquor technology, applied in the field of food processing, can solve problems such as quality differences, and achieve the effects of not easy to pour slurry, increase water absorption, and heat up quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

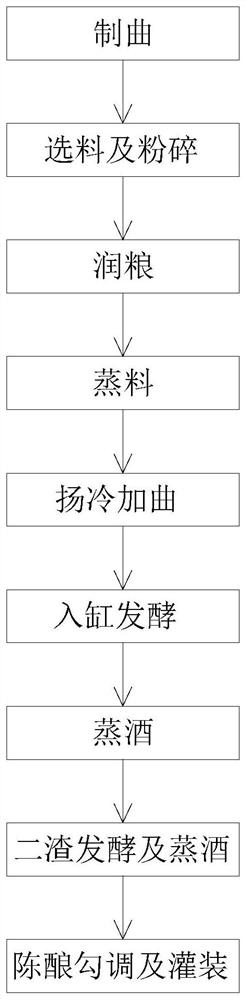

[0037] Below in conjunction with accompanying drawing and embodiment, liquor production process of the present invention is further described.

[0038] see figure 1 As shown, a liquor production process mainly consists of koji making, material selection and crushing, grain moistening, steaming, cooling and adding koji, fermentation in tanks, wine steaming, second-slag fermentation and wine steaming, aging blending and filling processes composition.

[0039] 1. The steps of making music are:

[0040] Wheat, peas and barley are selected as the raw materials for making koji. The raw materials are crushed and mixed evenly.

[0041] Among them, the blanks are pressed into 30-40 cm long, 10-15 cm wide, and 5-10 cm high specifications, and then sent to the pre-laid rice straw room, stacked on 5-8 layers, and each piece Reserve 5 cm spacing holes between them, reserve 30 cm gap between adjacent stacks for ventilation and moisture removal, and naturally ferment and mature for 30 day...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com