Microbial treatment technology for extracting nicotine

A technology of microbial treatment and nicotine, applied in the direction of organic chemistry, etc., can solve the problems of greater influence of water content on the solubility of tobacco raw materials, high investment and maintenance costs of high-voltage equipment, high requirements for design and manufacturing technology, and solve the problem of pollution discharge , Realize the effect of tobacco resource reuse and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A microbial treatment process for extracting nicotine is to use the microbial treatment process to ferment tobacco, which is completed according to the following steps:

[0023] (1) Wash 40g~50g of discarded tobacco leaves, dry them in the air, bake them in an oven at 80°C~110°C for 30min~2hr, take them out, crush them with a pulverizer, and pass them through molecular sieves of 20, 40, and 60 meshes respectively Tobacco leaves with a particle size of less than 60 mesh are obtained, packed in plastic bags, and set aside.

[0024] (2) According to the characteristics of microorganisms degrading plant tissues, the microbial strains of Mycobacterium albicans, Trichoderma korningina, and Pachysomyces were specially selected for inclined plane culture, first-level seed test tube culture, and second-level seed shake flask culture.

[0025] ① Incline cultivation

[0026] Wort yeast culture medium: Take a certain amount of barley malt, crush it, add water 4 times the amount of...

Embodiment 2

[0038] (1), dry the tobacco leaves at 105° C. for 1 hr, pulverize them, sieve through a 60-mesh sieve, select 10 g of tobacco leaves with a particle size less than 60 mesh, and treat them with microwaves with an output power of 900 W and a frequency of 2450 MHz for 30 s;

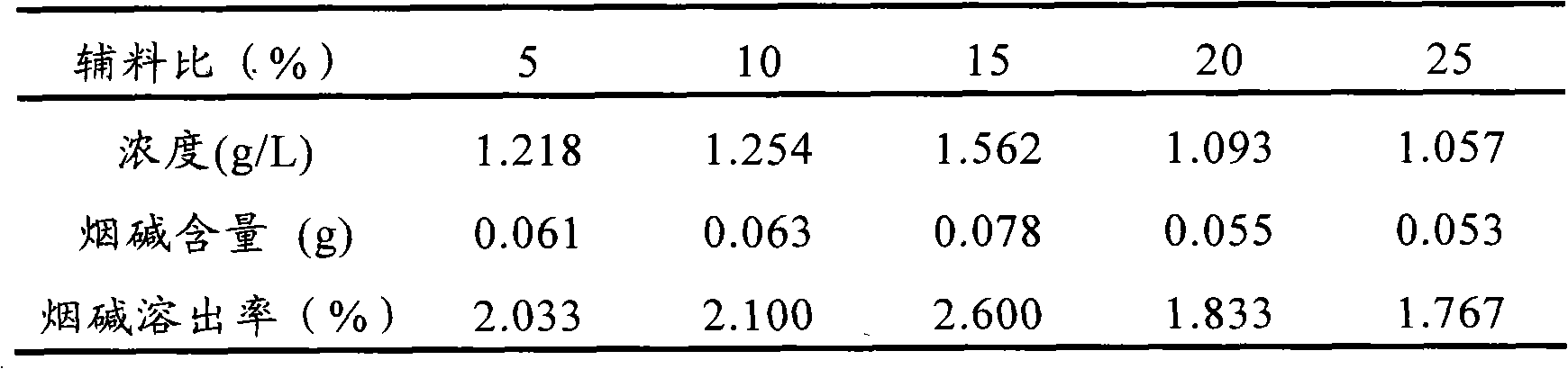

[0039] (2), choose the white rot fungus and Pachysomyces spp., after cultivating on an inclined plane and culturing the primary seed test tube, inoculate the two cultured strains into a 60ml 250ml Erlenmeyer flask at a ratio of 1:1 for secondary mixing Seed shaker culture, the amount of mixed strains introduced is 5%, 29°C, 180rpm, culture 48hr;

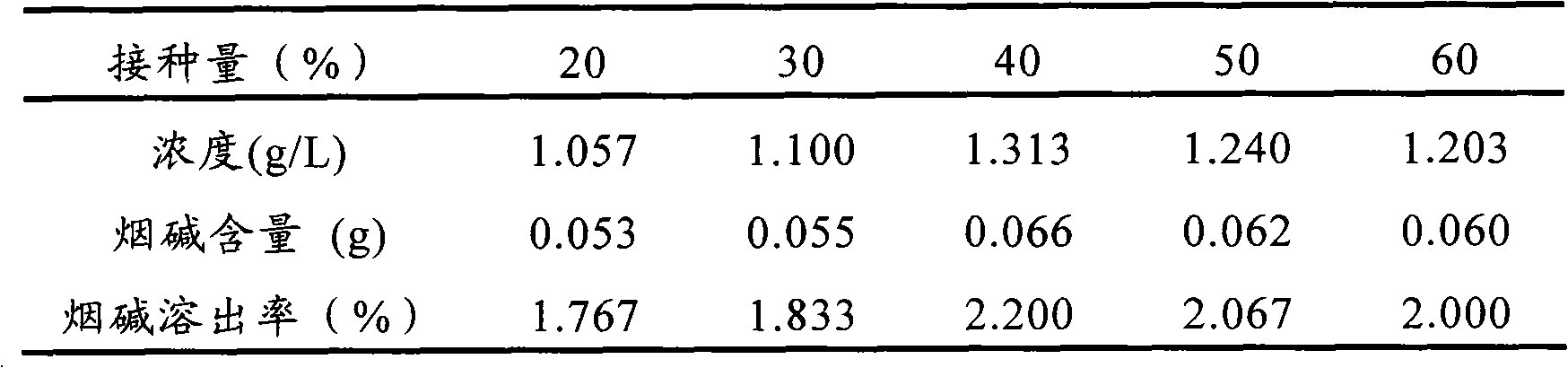

[0040] (3), the tobacco leaf 10g after the pretreatment of step (1) is transferred in the fermenter, adds the soybean meal of 1.5g and 60ml water, inserts the mixed strain that inoculum is 40% tobacco leaf weight in the fermenter, regulates The pH is 5, the temperature is 30°C, and 1ml of the sample is taken after fermentation for 48 hours. After centrifugation, the ...

Embodiment 3

[0043] (1), dry the tobacco leaves at 80° C. for 2 hours, pulverize them, sieve through 20 mesh and 60 mesh sieves, select 10 g of tobacco leaves with a particle size less than 60 mesh, and treat them with microwaves with an output power of 900W and a frequency of 2450mhz for 30s;

[0044] (2), choose the white rot fungus and Pachysomyces spp., after cultivating on an inclined plane and culturing the primary seed test tube, inoculate the two cultured strains into a 60ml 250ml Erlenmeyer flask at a ratio of 1:1 for secondary mixing Seed shaker culture, the amount of mixed strains introduced is 5%, 29°C, 180rpm, culture 48hr;

[0045] (3), the tobacco leaf 20g after the step (1) pretreatment is transferred in the fermenter, adds the soybean meal of 5g and 160ml water, inserts the mixed strain that inoculum is 60% tobacco leaf weight in the fermenter, adjusts pH 7, the temperature was 40°C, 1ml was sampled after 12 hours of fermentation, and after centrifugation, the nicotine con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com