Oil field steam-injection boiler heating system adopting solid thermal-storage electric boiler and two-stage heat exchange

A solid heat storage and heating system technology, applied in steam boilers, electrode boilers, steam boiler accessories, etc., can solve the problems of oilfield steam injection boiler combustion and emission pollution, and achieve the solution of alleviating the dilemma of consumption, reducing the cost and increasing the safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

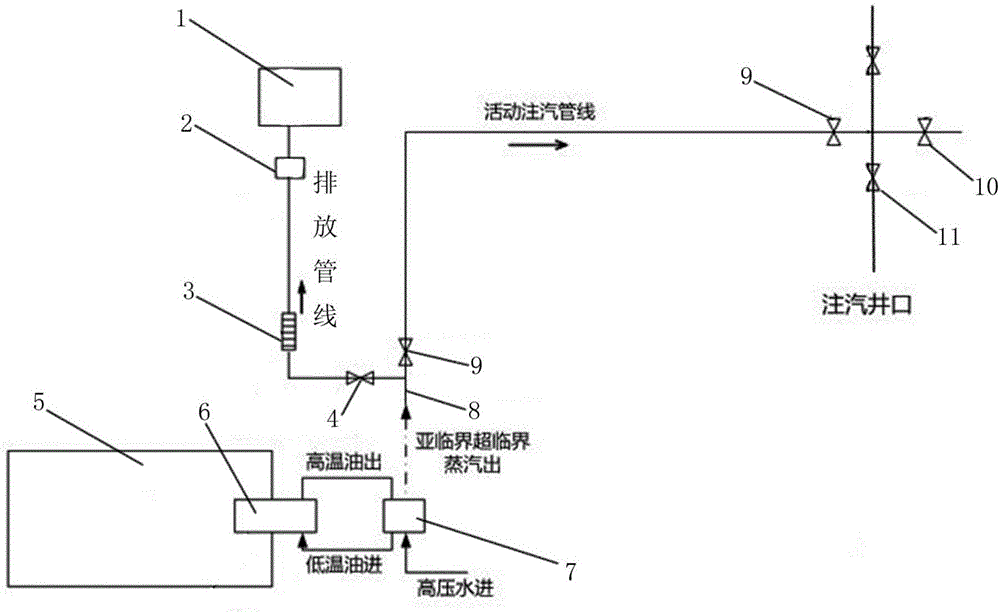

[0036] Such as figure 1 As shown, a solid heat storage electric boiler two-stage heat exchange oil field steam injection boiler heating system is preferred, including a heat source heating system, a steam injection system, and a discharge pipeline. The heat source heating system includes a solid heat storage electric boiler and a two-stage heat exchange system .

[0037] In this embodiment, the two-stage heat exchange system includes a high-temperature hot air and high-temperature hot oil heat exchanger 6, and a high-temperature hot oil and high-pressure hot water heat exchange steam generator two-stage heat exchange equipment.

[0038]In this embodiment, the solid heat storage electric boiler is connected to the high-temperature hot air and the high-temperature hot oil heat exchanger 6, and the solid heat storage electric boiler releases the heat storage heating air source to become high-temperature hot air; Inside, low-temperature oil is input and converted to high-temperat...

Embodiment 2

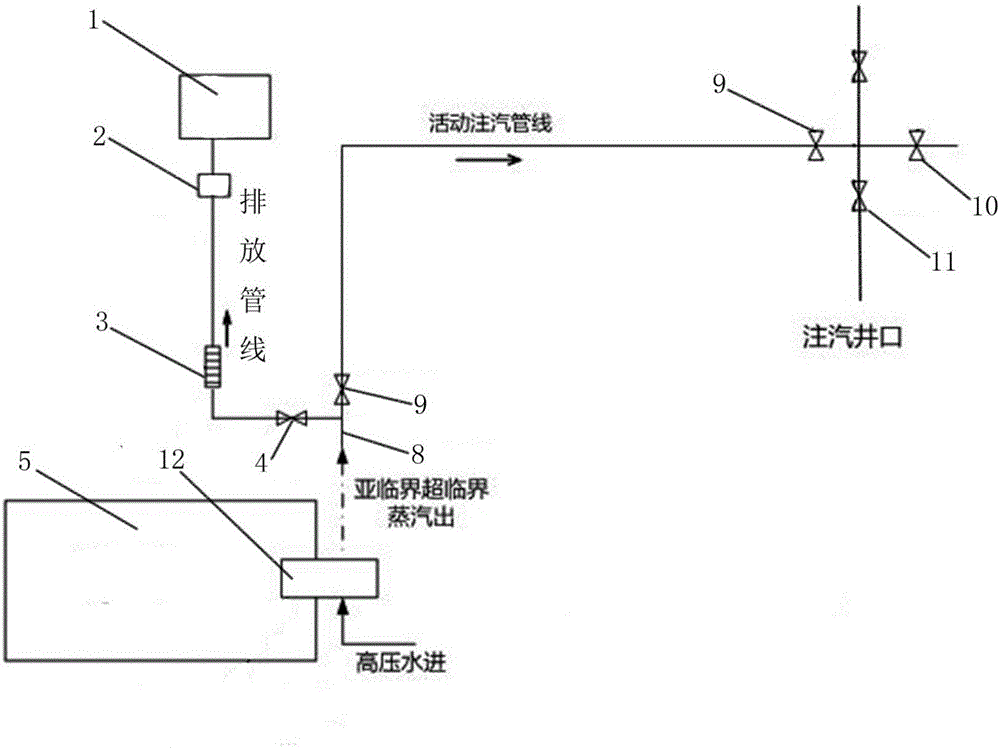

[0059] The two-stage heating system in the present invention can also be replaced by a specially designed high-pressure-resistant hot air-to-water steam generator and heat exchange equipment to become a single-stage heat exchange system. Such as image 3 As shown, a solid heat storage electric boiler single-stage heat exchange oil field steam injection boiler heating system is preferred, including a heat source heating system, a steam injection system, and a discharge pipeline. The heat source heating system includes a solid heat storage electric boiler and a single-stage heat exchange system .

[0060] In this embodiment, the single-stage heat exchange system includes a steam generator 12 for heat exchange between high-temperature hot air and high-pressure hot water. The high-temperature hot air and high-pressure hot water heat exchange steam generator 12 is preferably an economizer tube bundle heat exchanger arranged in the flue gas tail flue of a large-scale power plant bo...

Embodiment 3

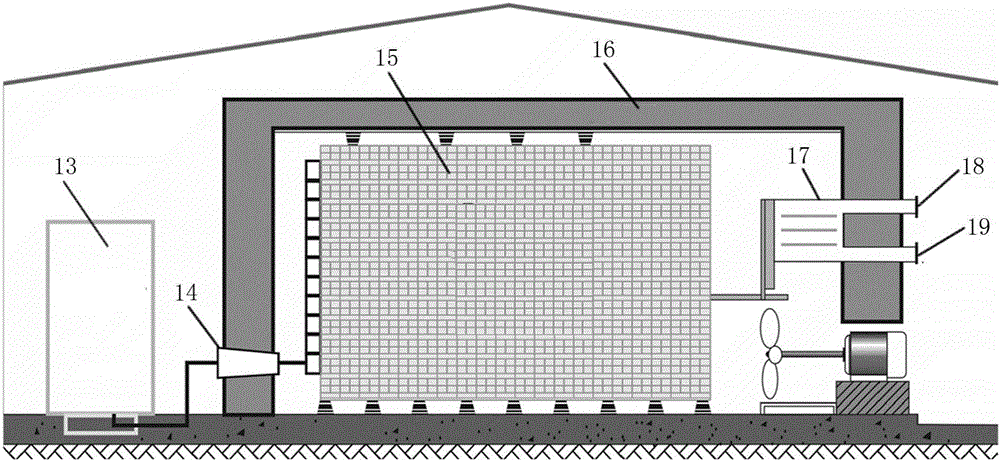

[0075] Embodiment 3 is similar to Embodiment 1, the difference is that Embodiment 3 also includes an intelligent control system, the intelligent control system is connected to the solid heat storage electric boiler, and the time for the high voltage resistor to store heat on the electric boiler can be controlled through the intelligent control system , That is, the solid heat storage electric boiler is intelligently started during the low power period at night, and the solid heat storage electric boiler is intelligently turned off during the day. The intelligent control system also includes a flow meter, a temperature sensor and an intelligent control valve arranged on the oil inlet / water pipe 19 and the oil / water outlet pipe 18. By detecting the flow and temperature, the output of heat energy is adjusted through the valve to save energy. At the same time, the temperature of oil and outlet steam can be controlled at a constant level.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com