Method for preparing oil-tea mushroom culture medium from tobacco stems and application

A technology of camellia oleifera mushroom and culture medium, which is applied in the directions of botanical equipment and method, application, mushroom cultivation, etc., can solve the problem of pollution discharge of tobacco waste, and achieve the effects of stable overall output, cost saving of raw materials, and favorable fermentation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Preparation of Camellia oleifera Medium:

[0042] (1) Raw material pretreatment: dry the tobacco stem naturally, and crush it through a 10-mesh sieve;

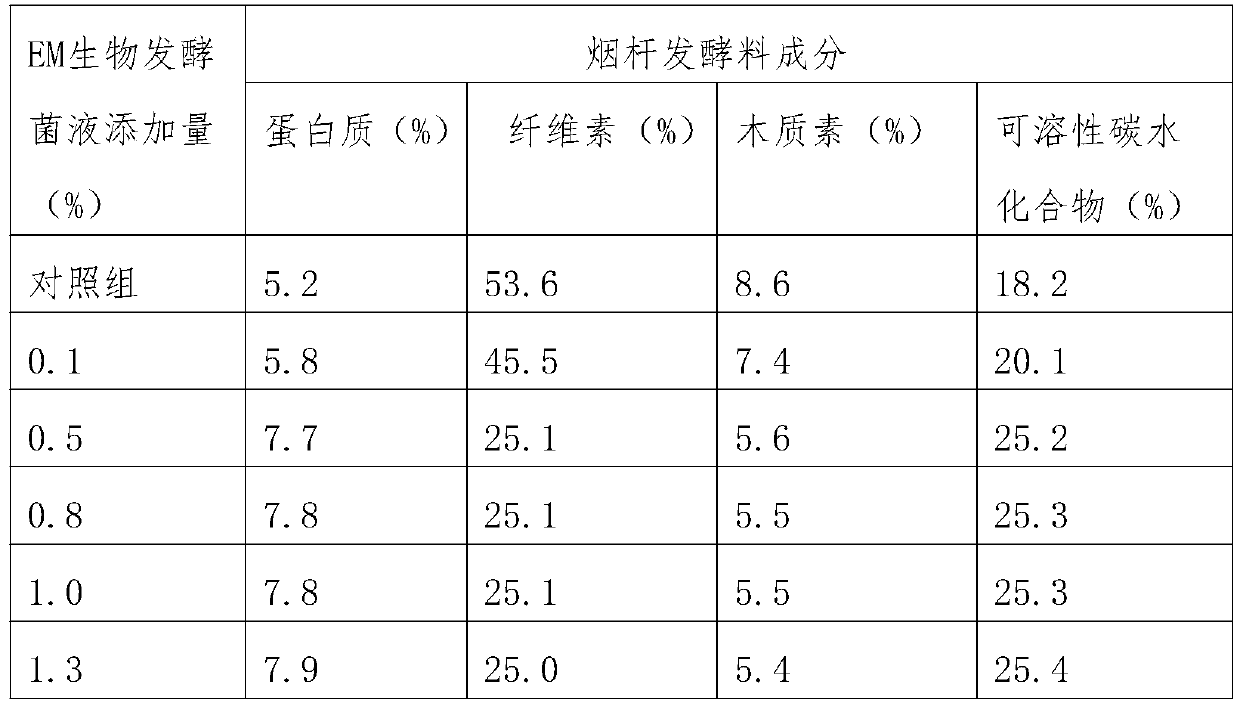

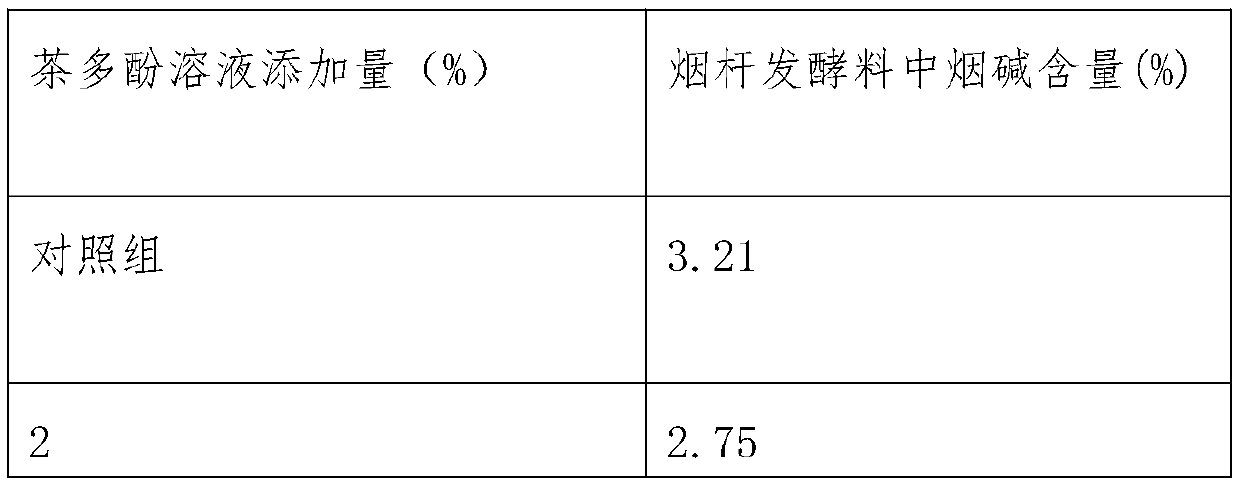

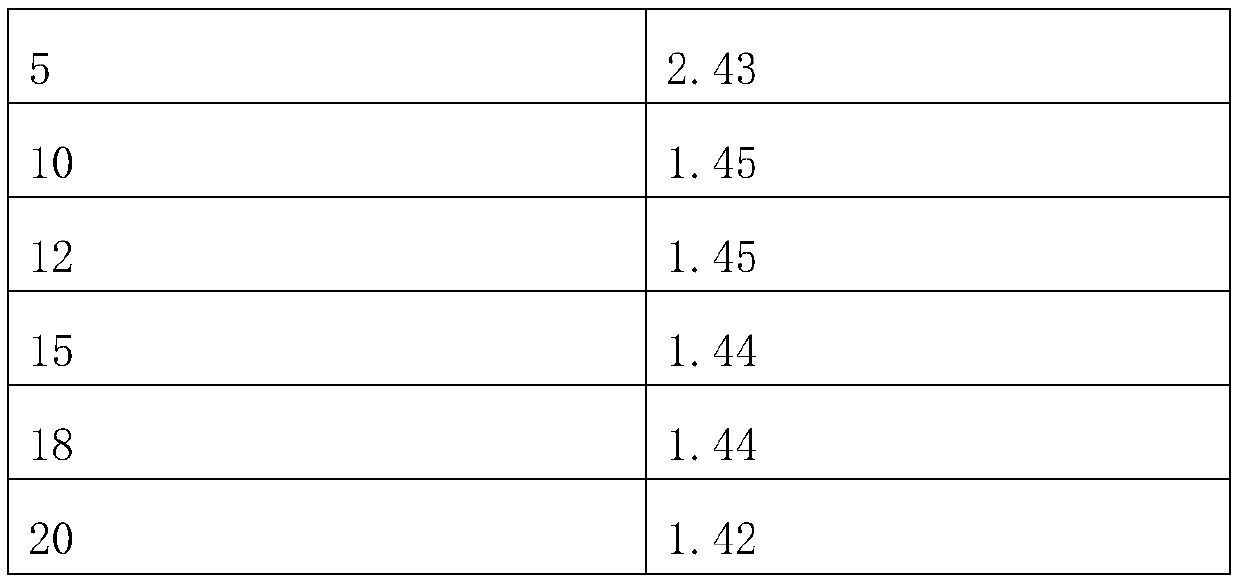

[0043](2) Tobacco rod fermentation: Add 0.5% of the weight of the EM biological fermentation bacteria liquid to the above-mentioned pulverized tobacco rod residue, and then spray 10% of the weight of the tobacco rod residue on the surface of the tobacco rod residue. The mass concentration is 20%. tea polyphenol solution; after stirring evenly, pile up and ferment. During the fermentation, the temperature of the stock pile rises to 60-65°C and turn over once for a total of three times until the color of the tobacco stalk slag becomes darker and the texture becomes soft, that is, Tobacco stem fermentation material;

[0044] (3) Culture medium preparation: mix according to weight ratio 50% of cottonseed hulls, 15% of wheat bran, 20% of fermented tobacco stem material, 5% of bagasse, 5% of soybean meal, 3% of king rice flo...

Embodiment 2

[0049] Preparation of Camellia oleifera Medium:

[0050] (1) Raw material pretreatment: dry the tobacco stem naturally, and crush it through a 20-mesh sieve;

[0051] (2) Tobacco rod fermentation: Add 0.6% of the weight of EM biological fermentation bacteria liquid to the above-mentioned pulverized tobacco rod residue, and then spray 12% of the weight of the tobacco rod residue on the surface of the tobacco rod residue with a mass concentration of 20%. Tea polyphenol solution; after fully stirring evenly, pile up and ferment. During the fermentation period, the pile temperature rises to 60-65°C and turn over once for a total of three times until the color of the tobacco stalk slag becomes darker and the texture becomes soft, that is Tobacco stem fermentation material;

[0052] (3) Culture medium preparation: mix according to weight ratio 40% of cottonseed hulls, 20% of wheat bran, 15% of tobacco stem fermented material, 10% of bagasse, 4% of soybean meal, 8% of king rice flou...

Embodiment 3

[0057] Preparation of Camellia oleifera Culture Medium

[0058] (1) Raw material pretreatment: dry the tobacco stem naturally, and crush it through a 30-mesh sieve;

[0059] (2) Tobacco rod fermentation: Add 0.8% of its weight EM biological fermentation bacteria liquid to the above-mentioned pulverized tobacco rod debris; Tea polyphenol solution; after fully stirring evenly, pile up and ferment. During the fermentation period, the pile temperature rises to 60-65°C and turn over once for a total of three times until the color of the tobacco stalk slag becomes darker and the texture becomes soft, that is Tobacco stem fermentation material;

[0060] (3) Culture medium preparation: according to the weight ratio of 30% cottonseed hulls, 25% wheat bran, 35% tobacco stem fermentation material, 5% bagasse, 1% soybean meal, 3% royal rice flour, and 1% gypsum ingredients, stir evenly, containing The water volume is controlled at 70%, and the pH value is adjusted to 7 with lime water t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com