System and process for storing and releasing electric energy

A storage system and process technology, applied in the direction of storage of electric energy systems, electrical components, etc., can solve problems such as unsatisfactory power development, low efficiency, energy storage limitations, etc., to solve large-scale storage problems, ease supply and demand, improve storage The effect of energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

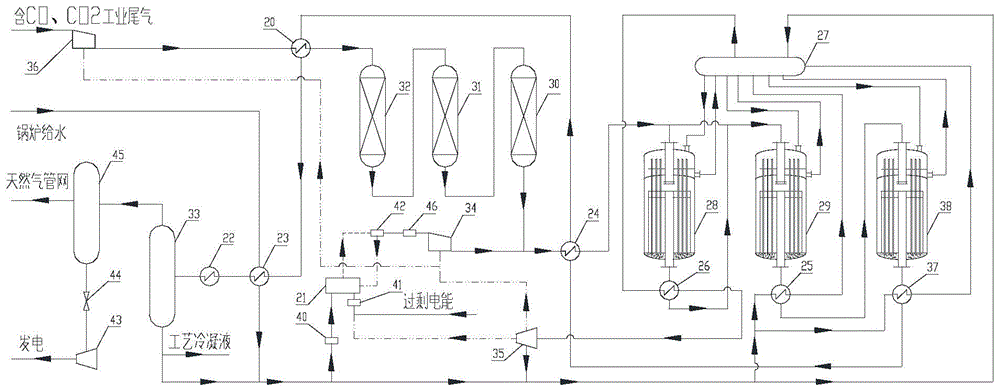

[0061] like figure 1 As shown, M=3.0 containing CO 2 , CO industrial tail gas, after dedusting and purification treatment, is pressurized and sent to 1# raw material heater 20 through carbon oxide gas compressor 36, and the purified gas after preheating passes through hydrolysis reactor 32, fine desulfurization reactor 31, deoxidation, After the denitrification reactor 30, the obtained purified gas has a sulfur content of 65ppb, a nitrogen content of 150ppm, and an oxygen content of 270ppm.

[0062] The wind power that is difficult to store and grid-connected is rectified by the AC / DC rectifier 41 and introduced into the manganese salt solution electrolytic cell 21 . The manganese salt solution electrolytic cell 21 obtains metal manganese, and the precipitated metallic manganese reacts with dilute sulfuric acid in the manganese dilute acid reaction device 42 to generate a large amount of hydrogen and manganese salt solution, and the manganese salt solution returns to the elec...

Embodiment 2

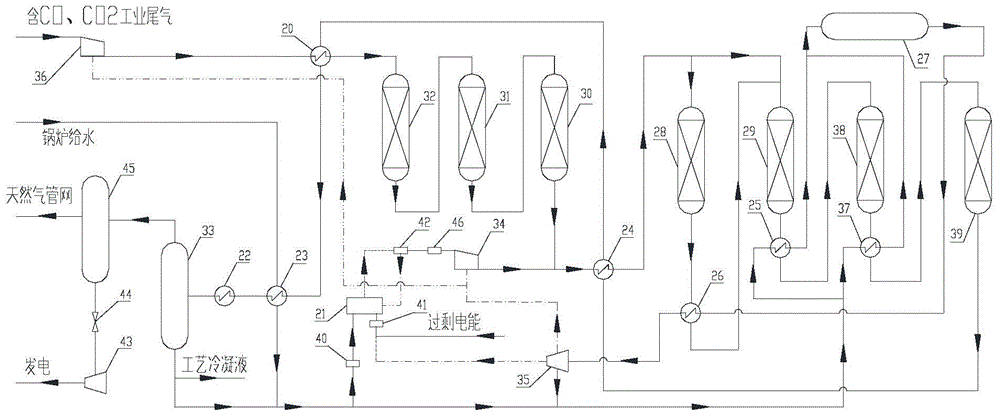

[0072] like figure 2 As shown, embodiment 2 is basically the same as embodiment 1, and the difference is: 1) use four radial bed reactors with diversion cone heat transfer instead of heat pipe reactor; 2) 1# methanation reactor outlet is set Steam superheater 26; 3) Medium pressure waste boiler 25 and medium pressure waste boiler 37 are installed at the outlets of 2# and 3# methanation reactors respectively; 4) 3# and 4# methanation reactors are connected in series. The specific process is as follows:

[0073] The electric energy generated by wind power and solar energy, which is difficult to store and grid-connected, is rectified by the AC / DC rectifier 41 and then introduced into the manganese salt solution electrolytic cell 21 . The manganese salt solution electrolytic cell 21 obtains metal manganese, and the precipitated metallic manganese reacts with dilute sulfuric acid in the manganese dilute acid reaction device 42 to generate a large amount of hydrogen and manganese ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com