High-temperature propylene chlorination process epichlorohydrin production waste water integrated treatment process

A technology for epichlorohydrin and a treatment process is applied in the field of integrated treatment process for producing epichlorohydrin wastewater by a high-temperature propylene chlorination method, which can solve the problems of low utilization rate, pollution discharge and the like, and achieve the effect of strengthening microbial enrichment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

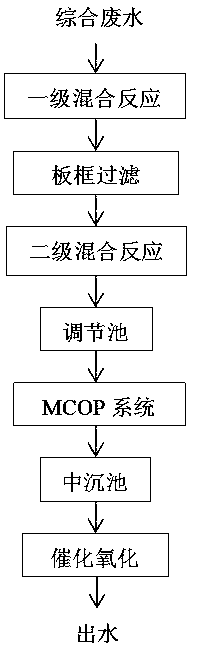

[0015] The present invention provides an integrated treatment process for the production of epichlorohydrin wastewater by high-temperature propylene chlorination. In order to make the purpose, technical scheme and effect of the present invention clearer and clearer, the present invention will be described in conjunction with the accompanying drawings and through specific implementation methods Further details. The embodiment of the present invention takes the annual production of 50,000 tons of epichlorohydrin as an example. It should be pointed out that the specific implementation described here is only for explaining the present invention, and is not intended to limit the present invention.

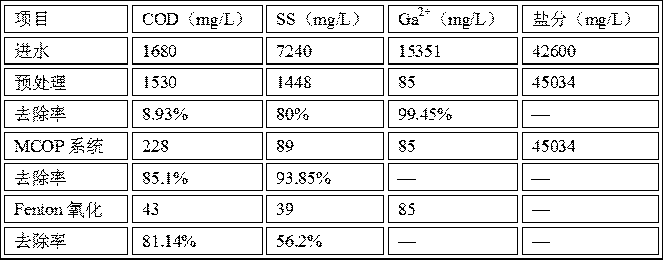

[0016] (1) The comprehensive wastewater enters the primary reaction tank, and the water quality of the epichlorohydrin comprehensive wastewater is as follows: COD is 1680 mg / L; total salt is 42600 mg / L; Ca 2+ 15351 mg / L; SS 7240 mg / L; waste water 420 m 3 / h. Add Na to the primary reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com