Blast furnace bottom joint filler and preparation method thereof

A technology of blast furnace and joint filler, which is applied in the field of metallurgical refractory materials, can solve the problems of hindering the performance of high thermal conductivity carbon bricks, high carbon porosity, and reduced thermal conductivity, and achieve strong adsorption capacity, chemical reactivity, and good suspension performance , the effect of high surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The blast furnace bottom joint filler of this embodiment, in parts by weight, includes: 100 parts by weight of dry material and 12 parts by weight of binder; wherein,

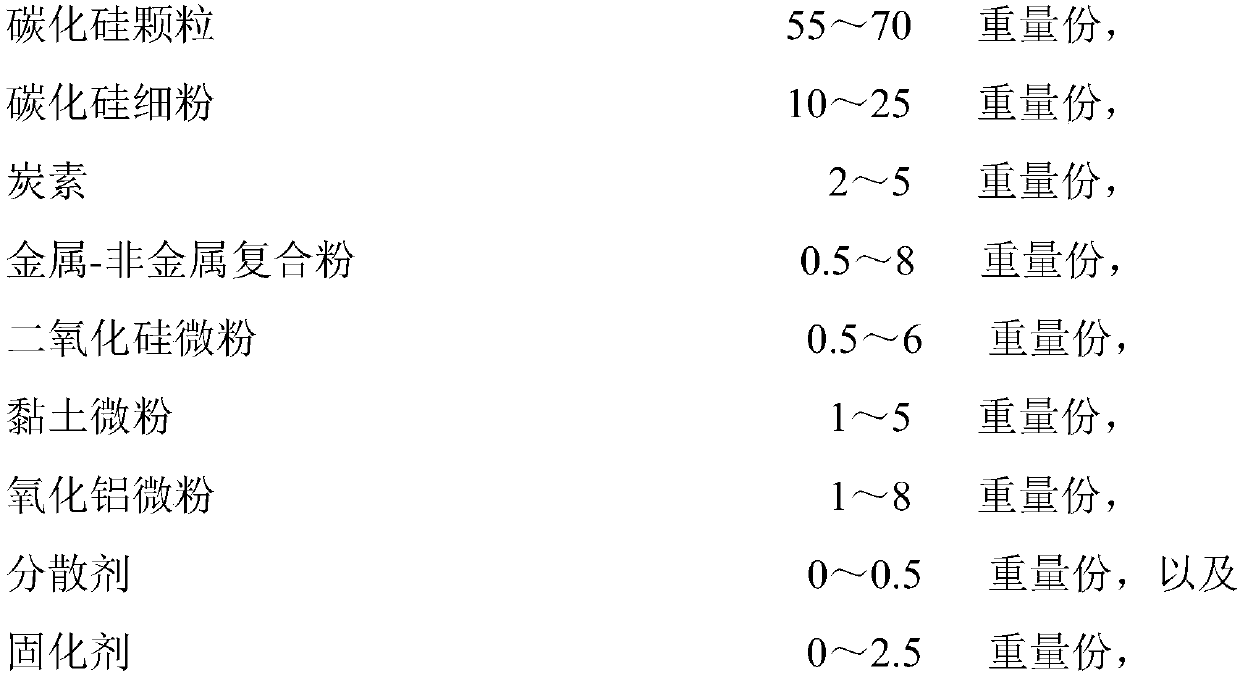

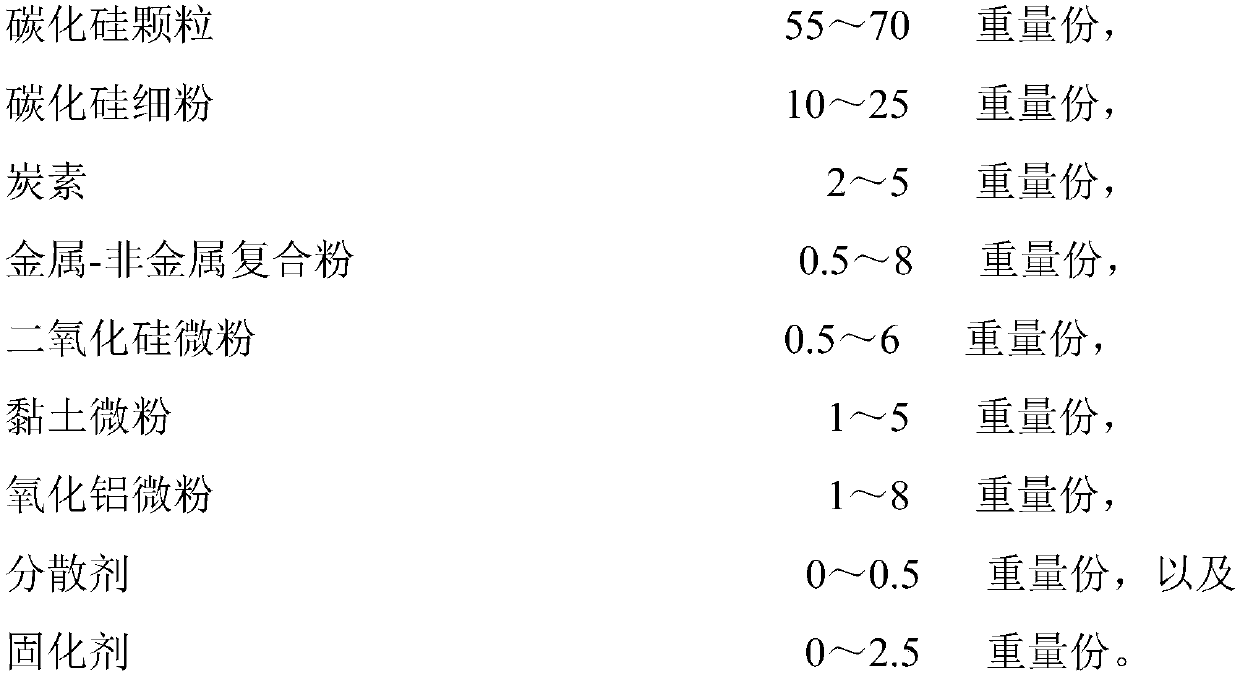

[0053] 100 parts by weight dry material contains:

[0054]

[0055] Among them, electrode powder, fixed carbon ≥ 92wt%, particle size ≤ 0.088mm;

[0056] In the metal-nonmetal composite powder, the total content of monocrystalline silicon and silicon dioxide is 34.47wt%, the content of silicon carbide is 62.58%, and the rest are impurities;

[0057] Silica powder, commercially available, refractory material, SiO 2 Content ≥ 92wt%, particle size distribution mainly concentrated in 0.5 ~ 2μm;

[0058] Clay powder, commercially available, refractory raw material, the particle size distribution is mainly concentrated in 15-45μm;

[0059] Alumina micropowder, commercially available, refractory raw material, the particle size distribution is mainly concentrated in 0.5-2μm;

[0060] The curing agent is m...

Embodiment 2

[0065] The blast furnace bottom joint filler of this embodiment, in parts by weight, includes: 100 parts by weight of dry material and 15 parts by weight of binder; wherein,

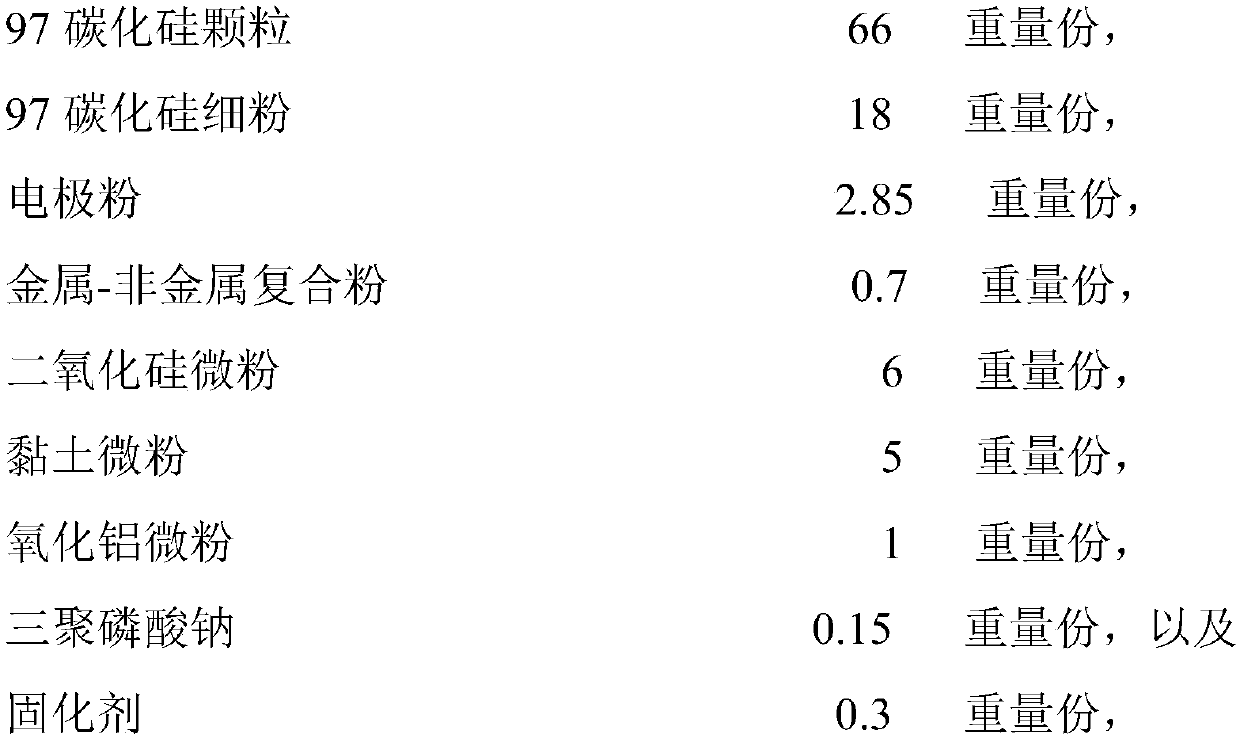

[0066] 100 parts by weight dry material contains:

[0067]

[0068]

[0069] Among them, electrode powder, fixed carbon ≥ 92wt%, particle size ≤ 0.088mm;

[0070] In the metal-nonmetal composite powder, the total content of monocrystalline silicon and silicon dioxide is 34.47wt%, the content of silicon carbide is 62.58%, and the rest are impurities;

[0071] Silica powder, commercially available, refractory material, SiO 2 Content ≥ 92wt%, particle size distribution mainly concentrated in 0.5 ~ 2μm;

[0072] Clay powder, commercially available, refractory raw material, the particle size distribution is mainly concentrated in 15-45μm;

[0073] Alumina micropowder, commercially available, refractory raw material, the particle size distribution is mainly concentrated in 0.5-2μm;

[0074] The curing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com