A high thermal conductivity high strength aluminum matrix composite material for die casting and its preparation method

An aluminum-based composite material and high-strength technology, which is applied in the field of metal-based composite materials, can solve problems such as poor thermal conductivity and difficulty in satisfying rapid heat dissipation of components, so as to improve thermal conductivity and strength, expand industrialization, and have a wide range of sources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

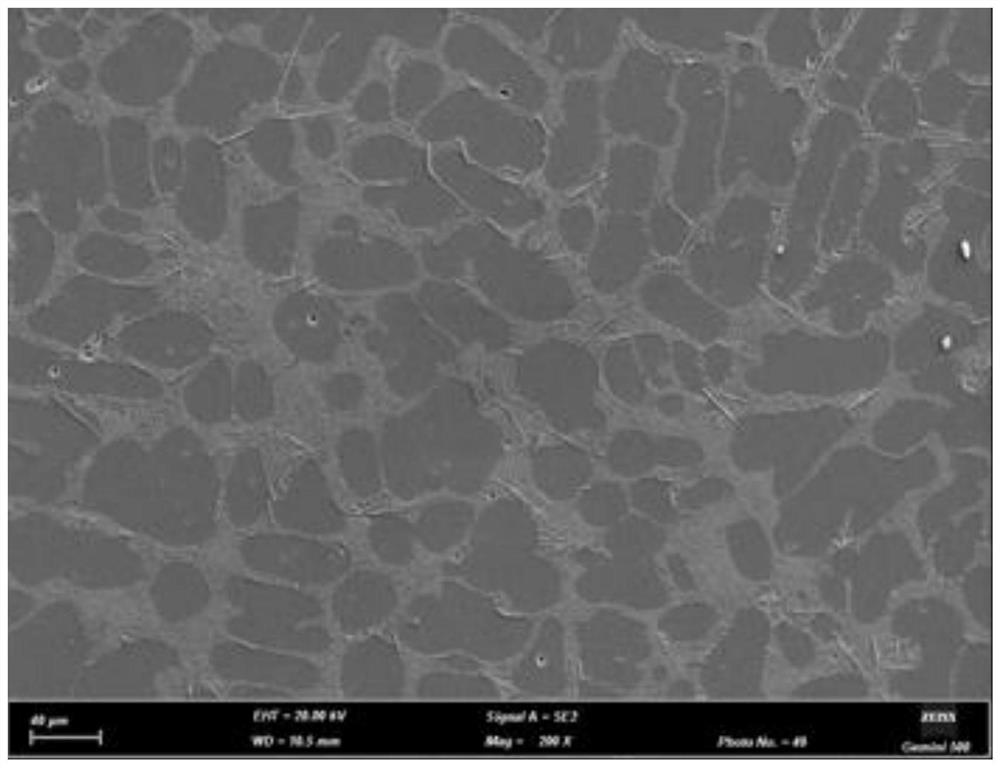

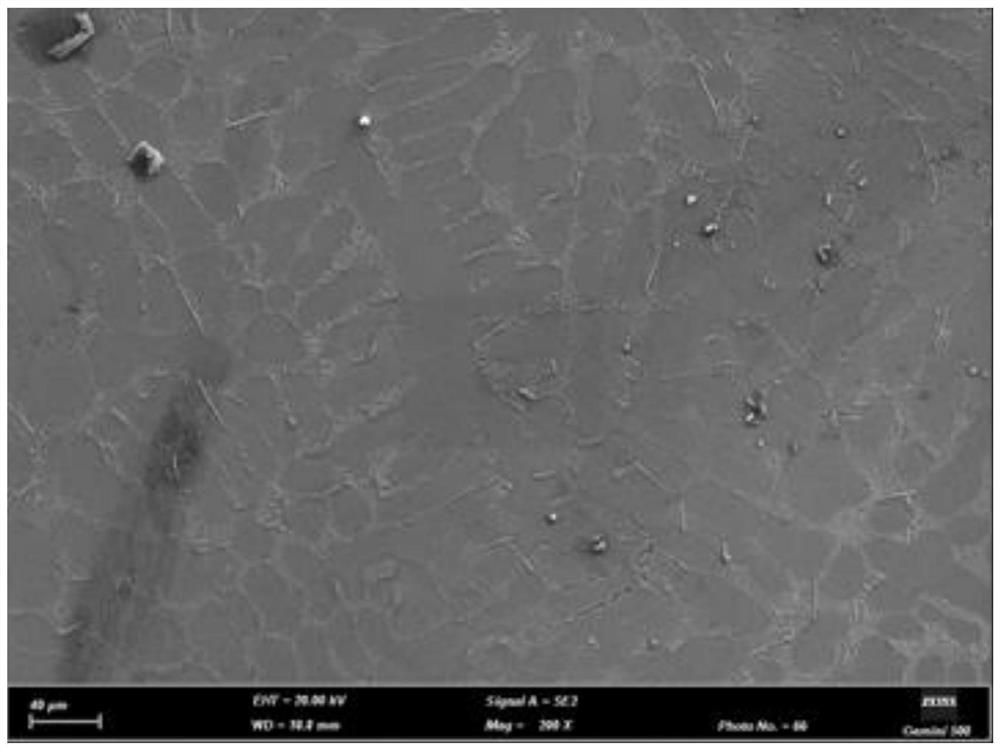

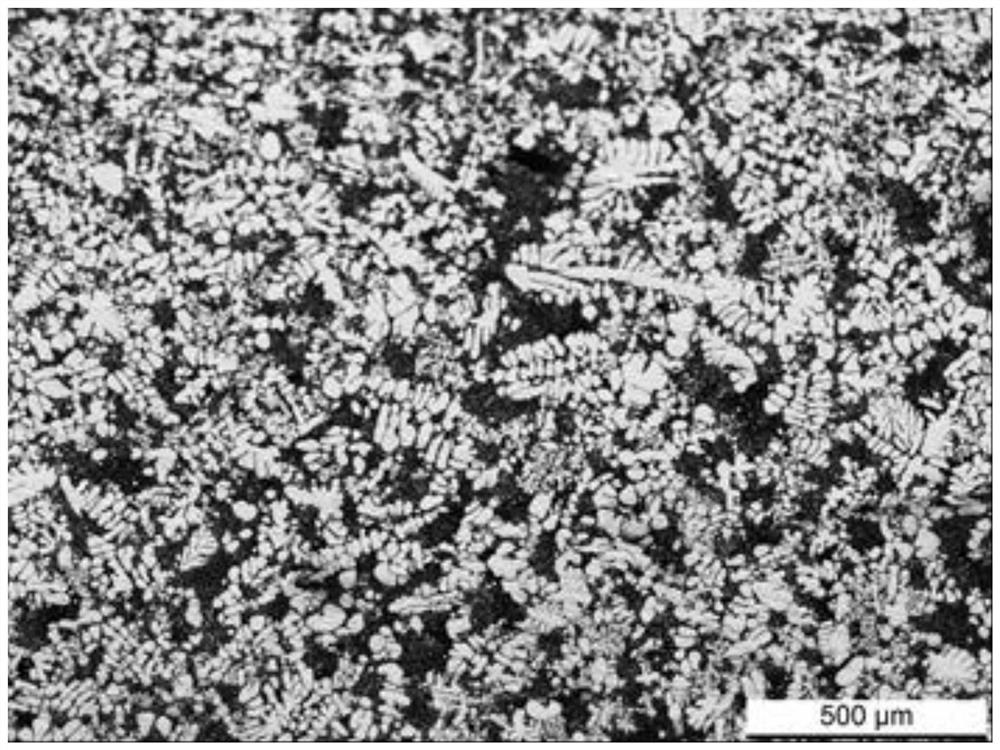

Image

Examples

preparation example Construction

[0049] The preparation method of the high thermal conductivity and high strength aluminum matrix composite material for die casting of the present invention specifically comprises the following steps:

[0050] S1) Weighing and drying raw materials: Weighing the aluminum alloy matrix and reinforcing particles according to the composition content, and placing the reinforcing particle mixture in a drying oven to dry;

[0051] S2) Melting: putting the preheated aluminum alloy substrate into a melting furnace for heating and melting to obtain a melting melt;

[0052] S3) Refining: After the smelting melt is completely melted, adding a refining agent and / or an inert gas to the smelting melt for refining to obtain a refining melt;

[0053] S4) Preparation of aluminum-based composite material melt: adding the dried reinforcing particles into the refining melt obtained in step S3) and stirring, removing surface slag inclusions to obtain an aluminum-based composite material melt;

[00...

Embodiment 1

[0061] The specific composition and mass fraction of the aluminum alloy matrix are: Si 4.0%, Fe 0.30%, Mg 0.10%, Cu0.10%, Sr 0.02%, La 0.10%, and the rest are Al and unavoidable impurities, among which unavoidable impurities The total mass fraction of elements is 0.05%; the reinforcing particles are SiC particles with an average particle size of 5 μm and a purity of 99.5% and AlB with an average particle size of 1 μm and a purity of 99%. 2 particles, among which SiC particles and AlB 2 The volume fractions of particles are 1% and 0.1%, respectively;

[0062] The preparation method of the aluminum matrix composite material with high thermal conductivity and high strength for die casting, the method specifically includes the following steps:

[0063] S1) Weigh and dry the raw materials: Weigh the pure Al and Al-12Si ingots, Al-10Fe and Al-5Sr master alloys, SiC particles and AlB required for the above-mentioned aluminum matrix composite materials according to the composition co...

Embodiment 2

[0070] The specific composition and mass fraction of the aluminum alloy matrix are: Si 10.0%, Fe 0.80%, Mg 0.80%, Cu 0.50%, Sr 0.12%, Ce 0.40%, and the rest are Al and unavoidable impurities. Among them, unavoidable impurities The total mass fraction of elements is 0.20%; the reinforcing particles are SiC particles with an average particle size of 25 μm and a purity of 99.5% and AlB particles with an average particle size of 20 μm and a purity of 99%. 2 particles, among which SiC particles and AlB 2 The volume fractions of particles are 5% and 0.5%, respectively;

[0071] The preparation method of the aluminum matrix composite material with high thermal conductivity and high strength for die casting, the method specifically includes the following steps:

[0072] S1) Weigh and dry raw materials: Weigh the pure Al and Al-12Si ingots, Al-10Fe and Al-5Sr master alloys, SiC particles and AlB2 particles required for the above-mentioned aluminum-based composite materials according t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com