Nanometer Na/Fe composite type solid acid catalyst and preparation method and application thereof

A solid acid catalyst and composite technology, applied in catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of low furfural selectivity, low selectivity, secondary There are many products, etc., to achieve the effects of cheap and easy-to-obtain raw materials, improved selectivity, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A method for preparing a nano-Na / Fe composite solid acid catalyst provided in an embodiment of the present invention comprises the following steps:

[0034] S1 weighs the required mass of FeCl 3 ·6H 2 O and FeCl 2 4H 2 O, put into deionized water and stir evenly to form a clear solution, add hydrochloric acid and stir, wherein, FeCl 3 ·6H 2 O and FeCl 2 4H 2 O by Fe 3+ :Fe 2+ The molar fraction ratio of the preparation is 2:1, the concentration of hydrochloric acid is 12mol / L, and the addition amount of hydrochloric acid is according to Fe 3+ :H + The mole fraction ratio is determined at 1.5:2;

[0035]S2 is gradually dripped into the NaOH solution under the agitation of the stirrer to produce red and black precipitates, until the pH of the solution is 2-6, the dropwise addition is completed, and the stirring is continued, and then it is allowed to stand for a period of time to drop to room temperature, wherein the concentration of the NaOH solution is 1mol / ...

Embodiment 1

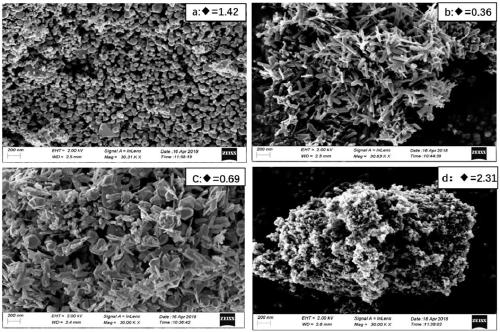

[0042] Weigh 31.62g of ferric chloride hexahydrate and 12.54g of ferric dichloride tetrahydrate, stir in 150ml deionized water to form a clear solution, add dropwise 5ml of 12mol / L hydrochloric acid and stir, then adopt forward coprecipitation method, in Under stirring with a magnetic stirrer at 60°C, 1.5mol / L NaOH solution was gradually added dropwise. At this time, a red-black precipitate was formed immediately, and the dropwise addition was completed when the Na / Fe mass ratio of the solution was equal to 1.42, and then continued to maintain a constant speed (800r / min ) and stirred for 1 hour, and left to stand for about 30 minutes to lower the temperature to room temperature. The reaction product was recovered by centrifugation, washed twice with 1600ml of deionized water, collected, and baked in an oven at 60°C for 12 hours to obtain a nano-Na / Fe composite solid acid catalyst.

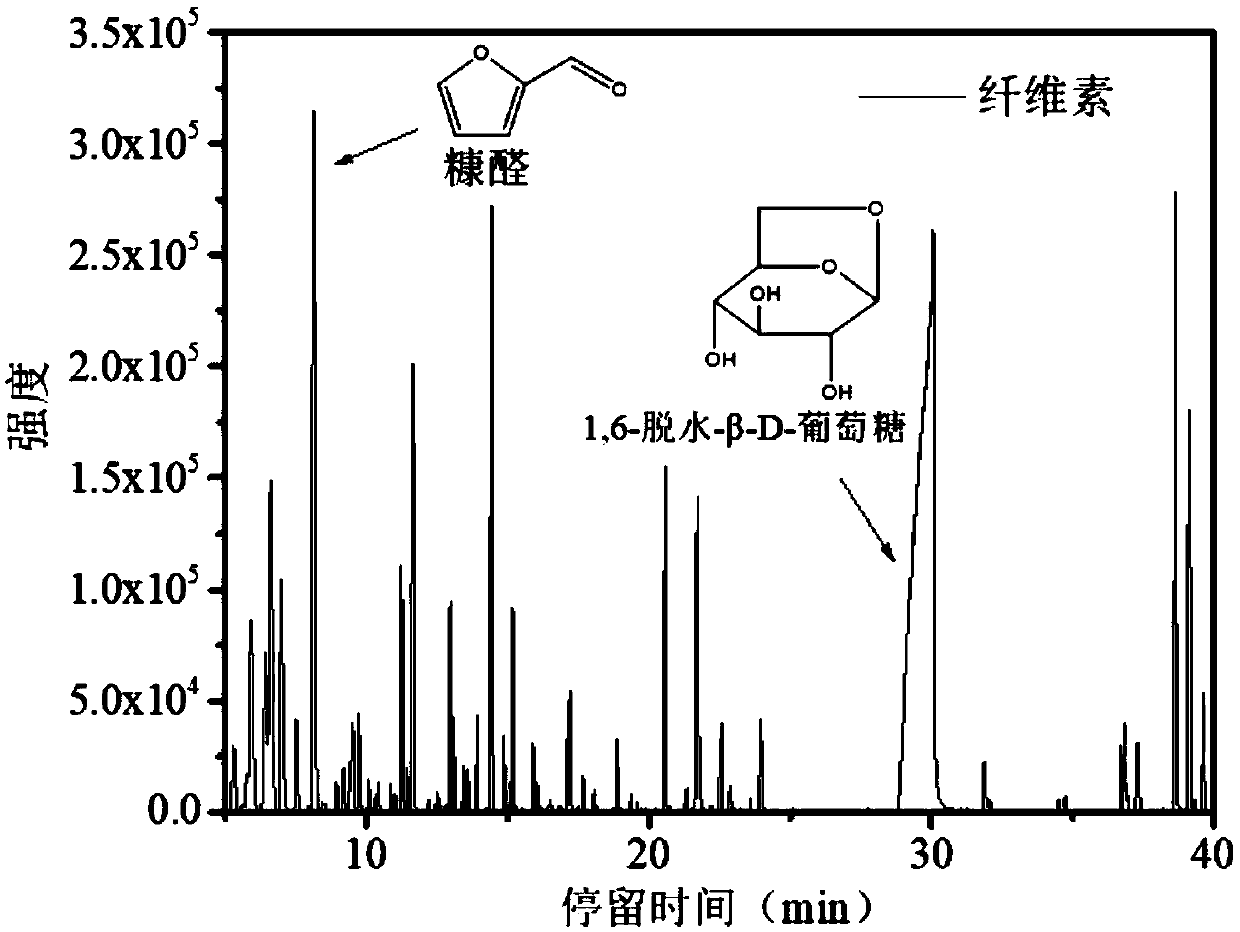

[0043] Using cellulose as raw material for catalytic pyrolysis, cellulose and nanometer Na / Fe c...

Embodiment 2

[0046] This example is the same as Example 1, except that the amount of NaOH added is prepared with a final Na / Fe mass ratio of 0.36, and other conditions are the same as Example 1.

[0047] figure 1 b is the SEM image of the catalyst prepared in Example 2, from which it can be seen that the catalyst has a rod-like morphology.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com