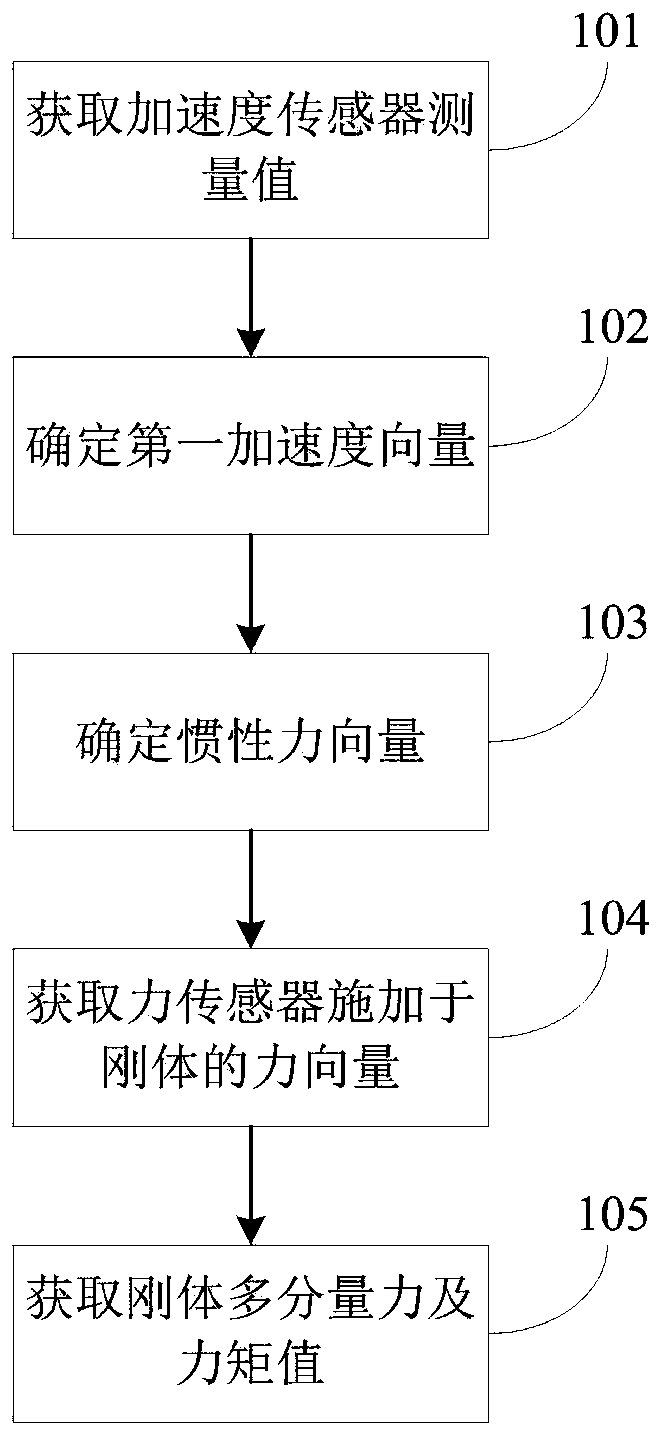

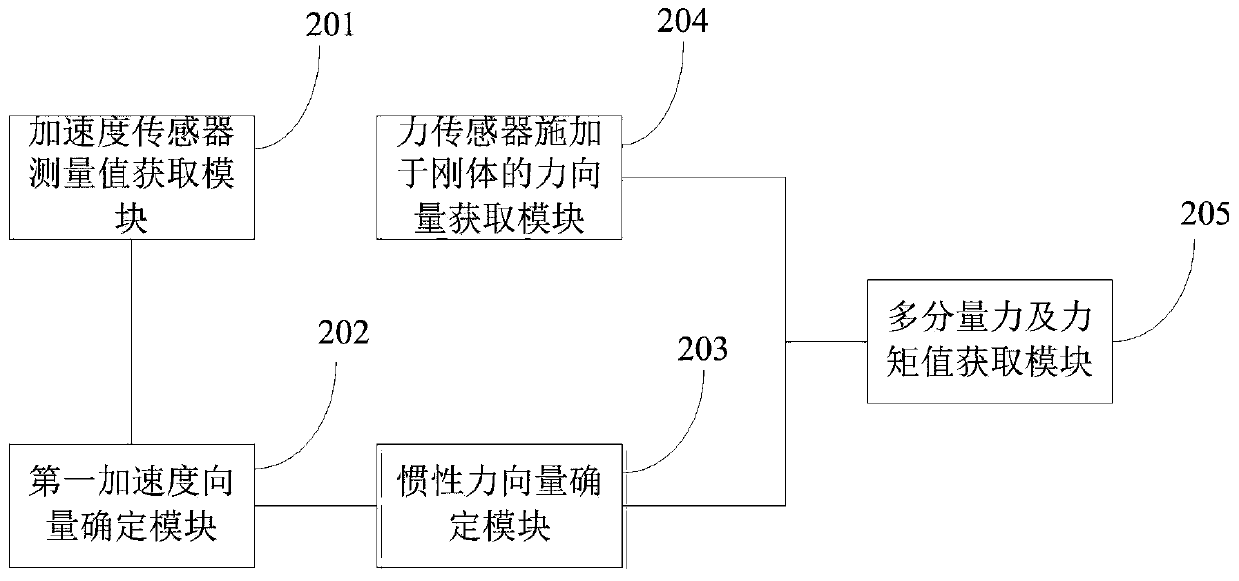

Method and system for measuring multi-component force and moment

A measurement method and multi-component technology, applied in the field of multi-component force and torque measurement methods and systems, can solve problems such as difficult to accurately measure rapidly changing force and torque input, difficult to set damping mechanism, and low damping ratio of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

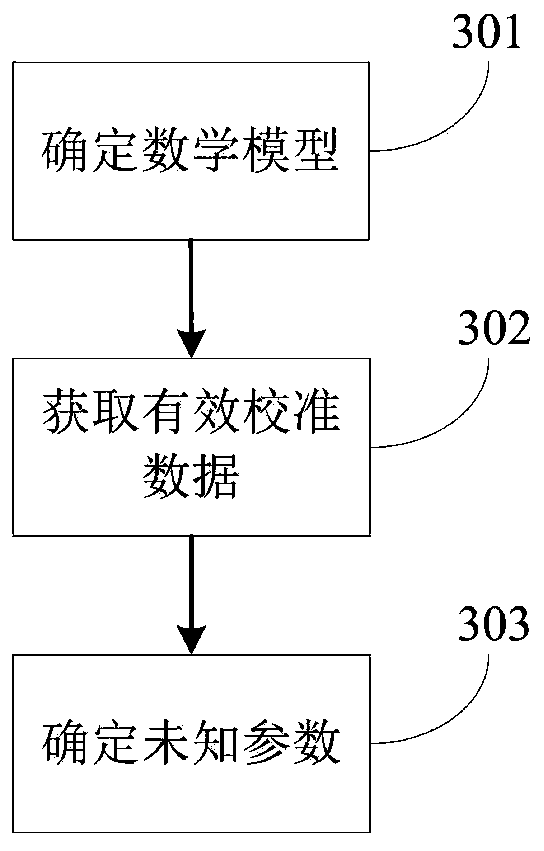

Method used

Image

Examples

Embodiment 1

[0141] Embodiment 1: adopt the above-mentioned process of the present invention to carry out 6 component force and moment measurement, the first-order and second-order derivatives in the data in the measurement process can be calculated by numerical difference, use amplitude-frequency characteristics such as Figure 5 As shown, the phase-frequency characteristic is calculated as a FIR filter of π / 2 plus a constant group delay.

[0142] Image 6 It is a schematic diagram of the measurement results of rapidly changing 6-component force and moment in Embodiment 1 of the present invention. The first 6 channels in the figure are the measurement results of the force sensor, and the last 6 channels are the corresponding fast-changing 6-component force and torque measurement results. Note the rapidly changing last three forces and moments (M x , M Z , M y ) The pulse that appears near the step moment of Y is caused by the loading method, not the error caused by this method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com