Adjusting method for imprint apparatus, imprinting method, and article manufacturing method

An adjustment method and a technology for adjustment steps, which are applied in the fields of adjustment of imprinting devices, imprinting, and article manufacturing, and can solve the problems of expensive molds, mold deterioration, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Hereinafter, exemplary embodiments of the present disclosure will be described with reference to the accompanying drawings.

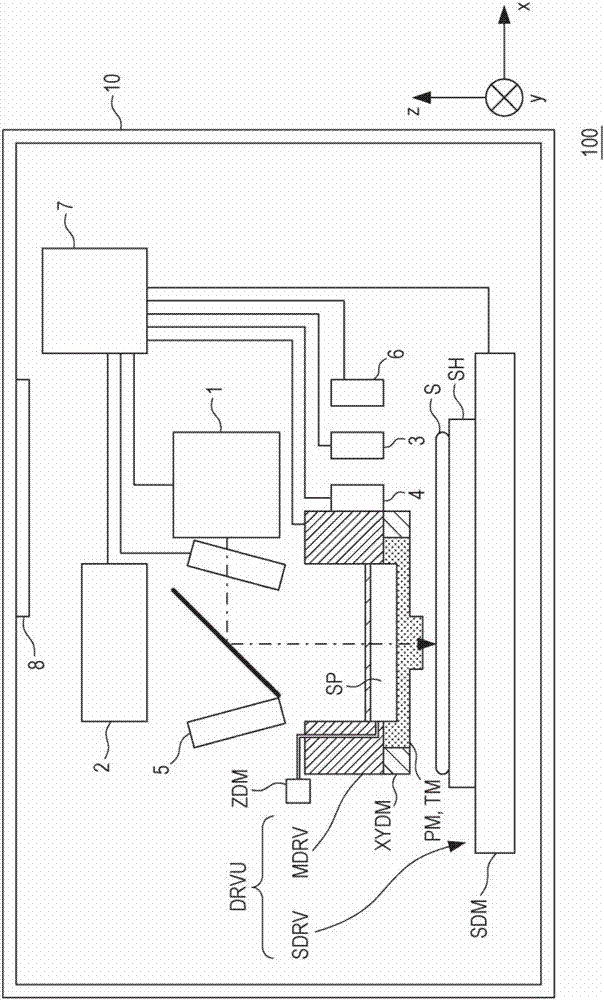

[0017] figure 1 The structure of the imprint apparatus 100 according to the embodiment of the present disclosure is schematically shown. The imprint apparatus 100 shapes an imprint material supplied on a substrate S using a mold (pattern model) PM, and forms a pattern on the substrate S by curing the shaped imprint material. Imprint materials are curable compositions that are cured by providing energy for curing the material. The imprint material can be in a cured or uncured state. The energy used for curing may be, for example, electromagnetic waves, heat, and the like. For example, the electromagnetic wave may be light (for example, infrared light, visible light, or ultraviolet light) whose wavelength is selected within a range of equal to or greater than 10 nm to less than or equal to 1 mm.

[0018] Typically, curable compositions are cure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com