Membrane recycling assembly

A technology of membrane components and needle components, which is applied in the field of agricultural machinery, can solve problems such as damage, reduction in plowing, land preparation operation efficiency, and crop yield reduction, achieving high efficiency, good automation of membrane removal, and low power demand.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

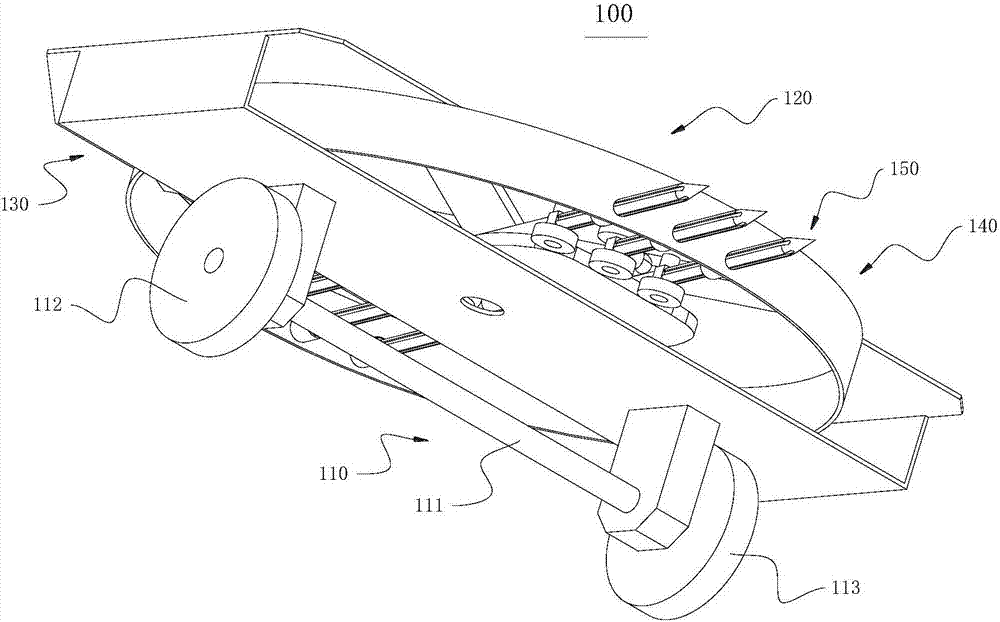

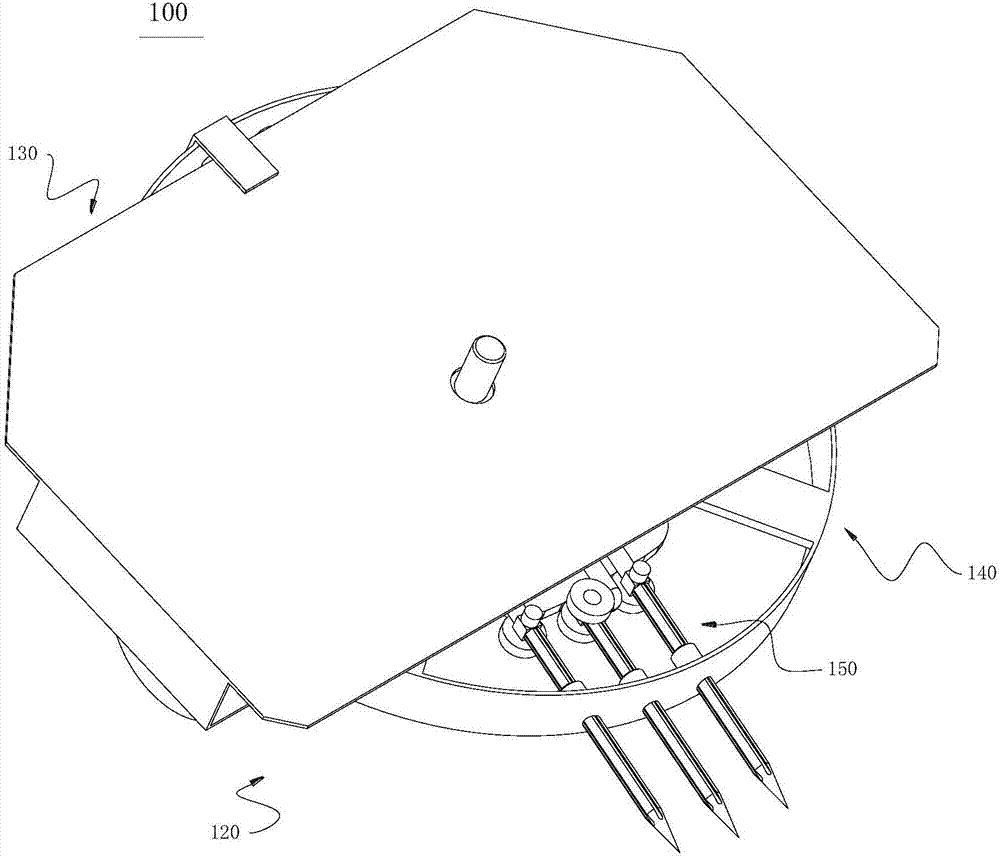

[0028] Please also refer to figure 1 and figure 2 , the present embodiment provides a residual film recycling machine 100 , including a driving and moving device 110 and a film removing assembly 120 connected to the driving and moving device 110 .

[0029] Specifically, the driving and moving device 110 includes an installation shaft 111 and a first roller 112 and a second roller 113 disposed on the installation shaft 111 . The first roller 112 and the second roller 113 are respectively rotatably arranged at two ends of the installation shaft 111 , in order to drive the film lifting assembly 120 to move by driving the moving device 110 .

[0030] The film removal assembly 120 includes a fixed support 130 , a rotating support 140 and three film removal needle assemblies 150 arranged side by side.

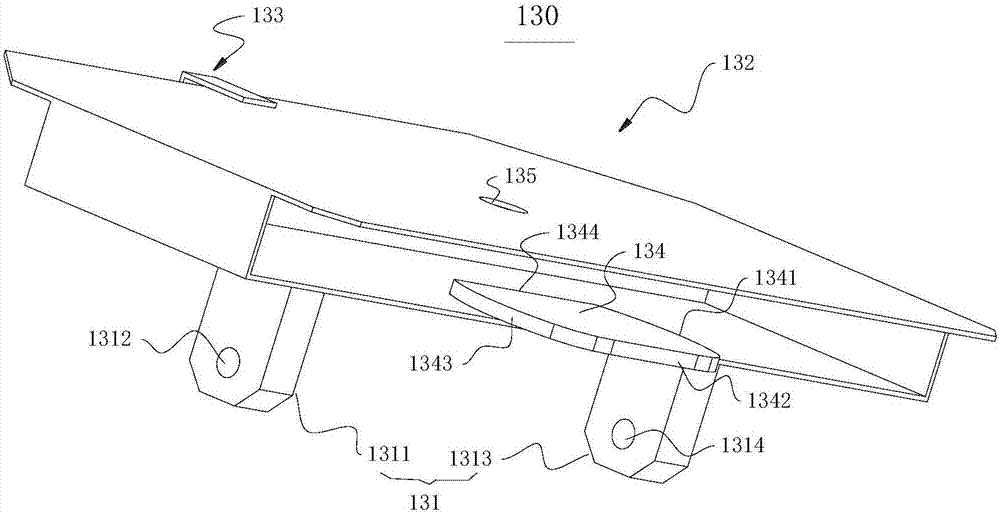

[0031] see image 3 The fixed bracket 130 includes a frame body 132 and a connecting piece 131 fixedly connected with the bracket. The connecting piece 131 includes a first conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com