Super-hard grinding wheel production line and conveying device thereof

A conveying device and production line technology, applied in grinding devices, transportation and packaging, metal processing equipment, etc., can solve the problems of large power required for mold pushing, increased energy consumption and production cost, and achieve low conveying resistance, The effect of reducing energy consumption and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

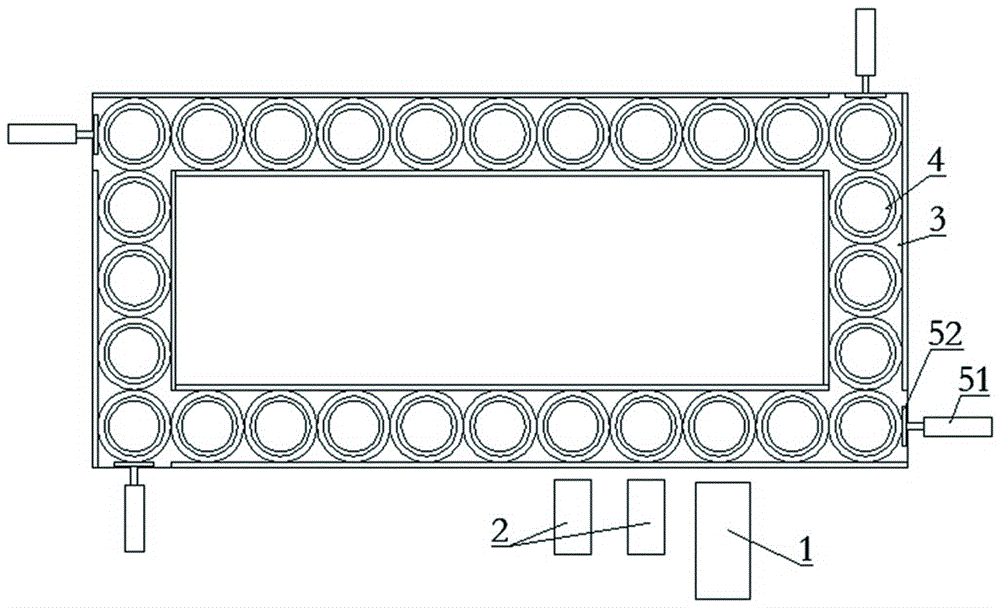

[0018] The embodiment of superhard emery wheel production line of the present invention: as figure 1 As shown, the production line includes a conveying device and a batching device 1 and a spreading device 2 arranged sequentially along the conveying direction on it, wherein the batching device 1 adopts a vibrating feeder, and the spreading device 2 is a spreading device with a spreading scraper. Mechanism, and there are two spreading devices 2, which are arranged in turn along the conveying direction to realize rough spreading and fine spreading. The conveying device is mainly composed of a conveying chute 3, a pushing device and a mold 4.

[0019] The outer peripheral surface of the mold 4 is a cylindrical surface, and the outer peripheral surface of the mold 4 is in rolling fit with the groove wall surface of the conveying chute 3 .

[0020] The cross-section of the conveying chute 3 is rectangular, and the conveying chute 3 is a quadrilateral circular conveying track formed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com