Pair of shoes equipped with welt having multi-color side wall

A technology of side walls and welts, applied in shoe uppers, footwear, boot legs, etc., can solve the problems of poor tortuosity, degumming, and incomplete adhesion of shoes, improve appearance variability, reduce thickness and weight, and improve tortuous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

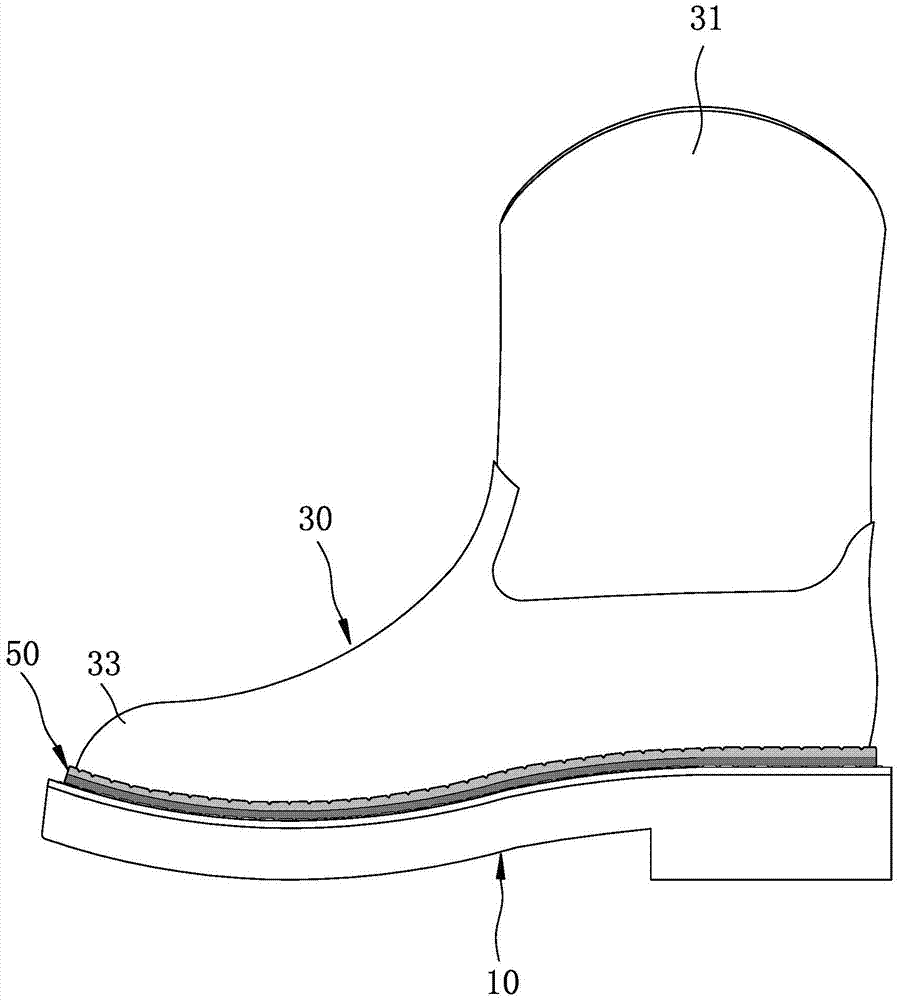

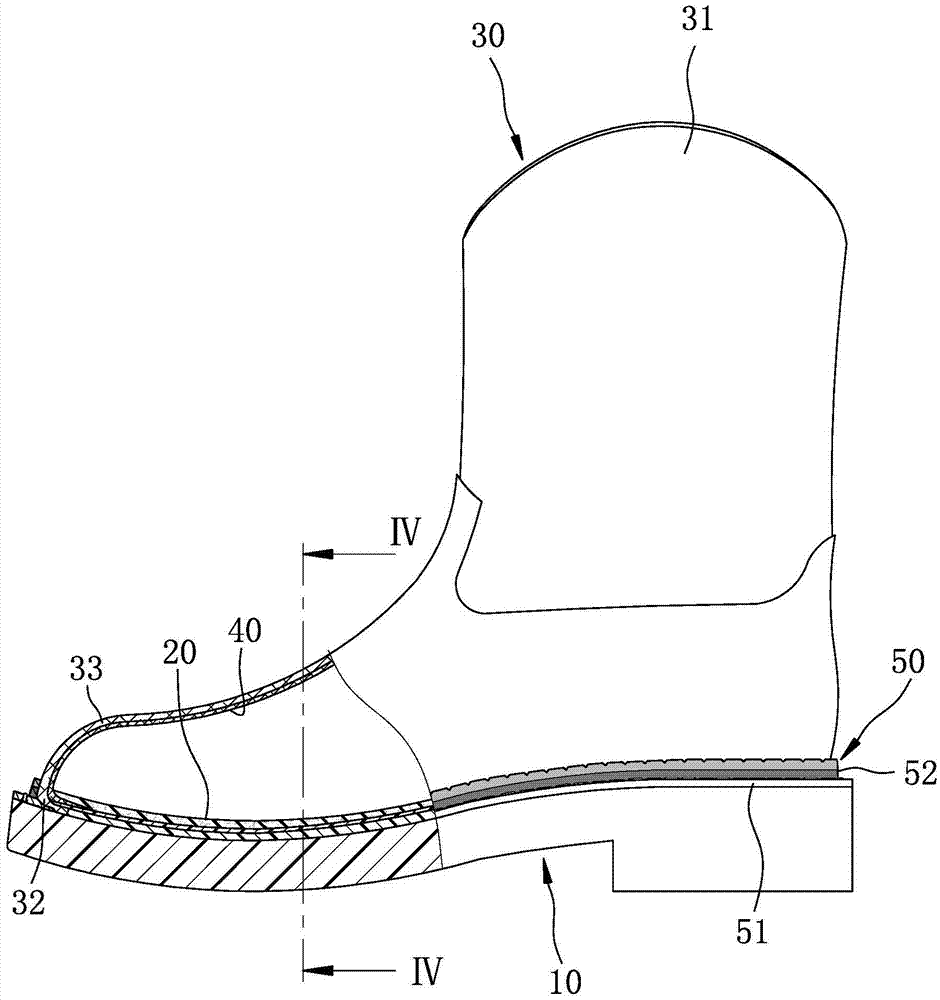

[0030] refer to figure 2 , 3 , is the first embodiment of the shoes with multi-color welt side walls of the present invention, the shoes with multi-color welt side walls include: a sole unit 10, a midsole plate 20, a vamp unit 30, an inner liner Li 40, and a welt unit 50.

[0031] The upper unit 30 is arranged on the sole unit 10, and has a top open end 31, a bottom open end 32 connected with the sole unit 10, and a bottom open end 31 between the top open end 31 and the bottom open end. Toe portion 33 between portions 32 .

[0032] In this embodiment, the inner lining 40 is disposed inside the upper unit 30 .

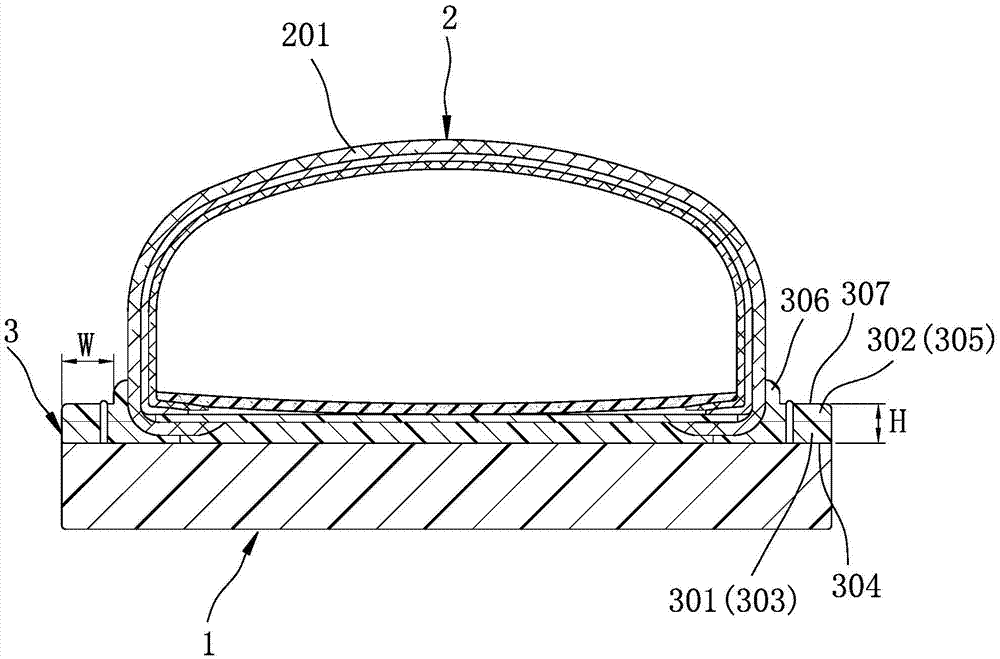

[0033] Such as image 3 , 4 , 5, the strip unit 50 is arranged on the top surface of the sole unit 10, and extends along a length direction L, the strip unit 50 has a base 51, a side wall 52 arranged on the base 51 , a flange 53 integrally extending inwardly from an inner end of the base 51 , and a suture 54 sewn on the base 51 . The flange piece 53 has a contin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com