Adjustable baffling lamella settler

An adjustable technology for inclined plate sedimentation, applied in the direction of sedimentation separation, flocculation/sedimentation water/sewage treatment, settling tank, etc., can solve the problem of single sedimentation efficiency in the form of inclined plate sedimentation tank, so as to facilitate sludge discharge and improve efficiency , The effect of reducing manufacturing and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

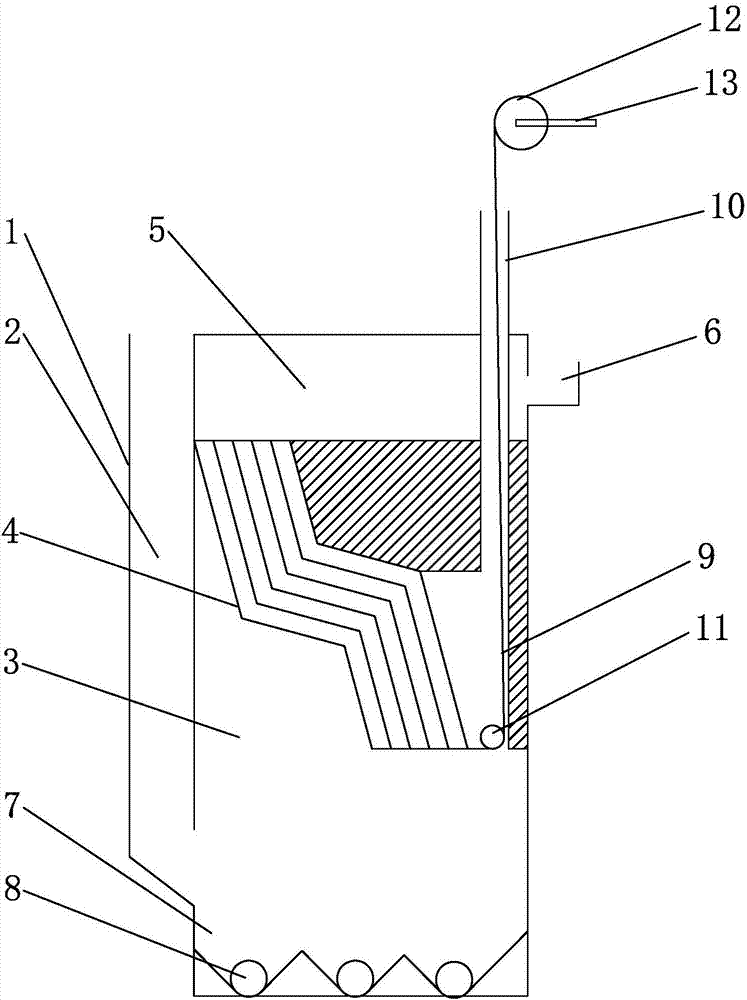

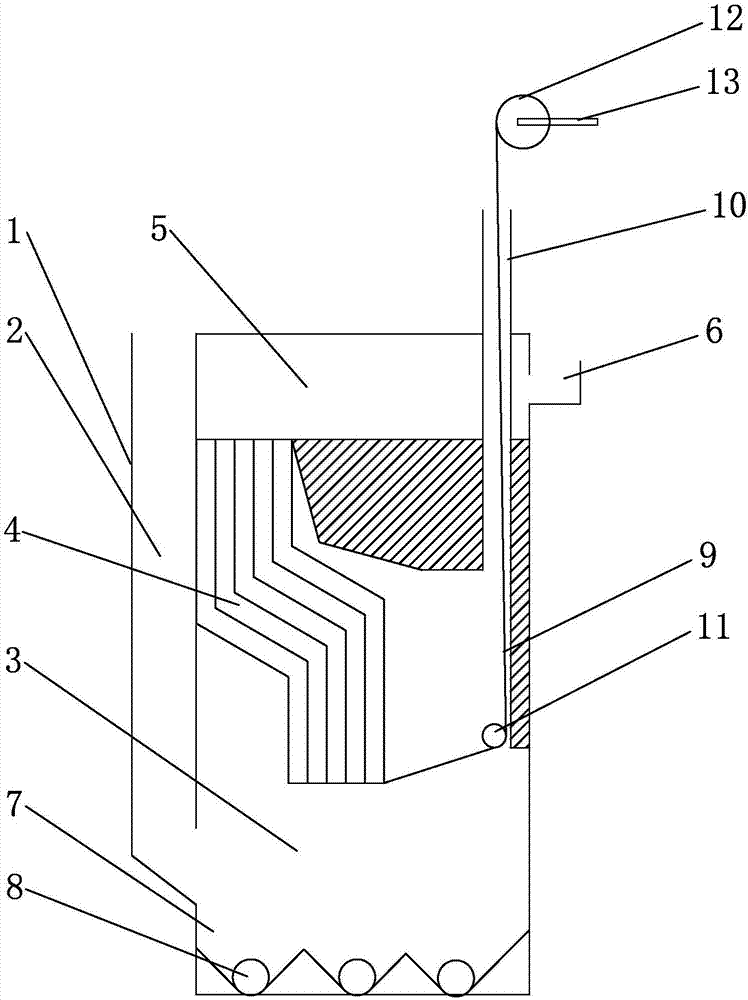

[0020] In order to solve the problems that the inclined plate sedimentation tank has a single form and the sedimentation efficiency needs to be further improved, the present invention proposes an adjustable baffle inclined plate sedimentation tank.

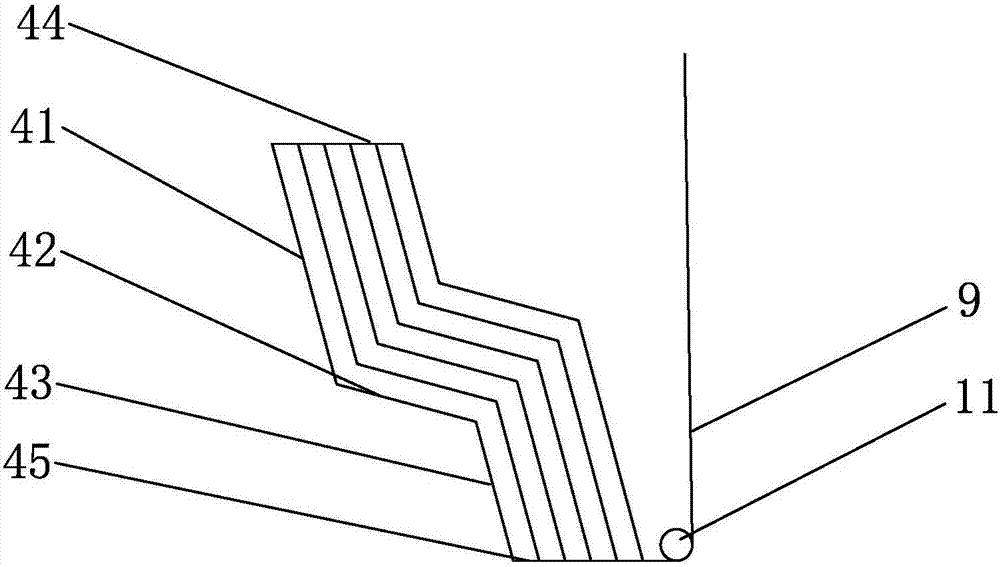

[0021] Including shell 1, water inlet channel 2, sedimentation area 3, baffle inclined plate 4, clear water area 5, water outlet 6, mud bucket 7, mud pipe 8, control rope 9, pipeline 10, pulley 11, hinge wheel 12 , Handle 13.

[0022] Sewage enters the sedimentation zone 3 of the sedimentation tank through the water inlet channel 2, and after the sedimentation of the baffle swash plate 4, the clear water enters the clear water zone 5 and is discharged from the water outlet tank 6; the sedimented sludge falls into the sedimentation zone 3 and then falls Enter the mud bucket 7, and after the mud bucket 7 is full, the sludge is discharged from the mud discharge pipe 8.

[0023] There are multiple baffle swash plates 4, and each baffle swas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com