Biogas-fermentation settling pond

A biogas fermentation and sedimentation tank technology, applied in filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of difficult to control the flow speed of manure and sewage, large floor space, poor sedimentation effect, etc., to facilitate daily management. and maintenance, increase the flow distance, improve the effect of sedimentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific implementation, structure, features and effects provided by the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

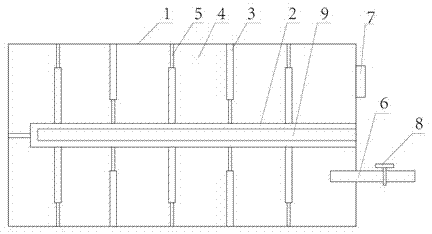

[0013] Such as figure 1 The shown biogas fermentation sedimentation tank includes a rectangular pool body 1, the pool body includes a central wall 2 and a partition 3, the central wall 2 is arranged on the center line of the pool body along the square shape of the pool body, and the central wall Only one end of the body is connected to the pool body 1, and a plurality of partitions 3 perpendicular to the central wall are arranged in the pool body, which divides the pool body into a plurality of sedimentation units 4, and two adjacent partitions 3 are connected to the central wall respectively. 2 or the pool body 1 is connected, so that the entrances of the two connected sedimentation units are staggered, and a filter plate 5 is provided between each partition 3 and the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap