A kind of acrylate composite grouting filling material and its preparation method and application

A technology of composite grouting and filling materials, applied in application, soil conditioning materials, chemical instruments and methods, etc., can solve problems such as low compressive strength, environmental impact, difficulty in meeting engineering needs, etc., and achieve good toughness and chemical corrosion resistance Good adhesion, good bond strength, and good injectability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

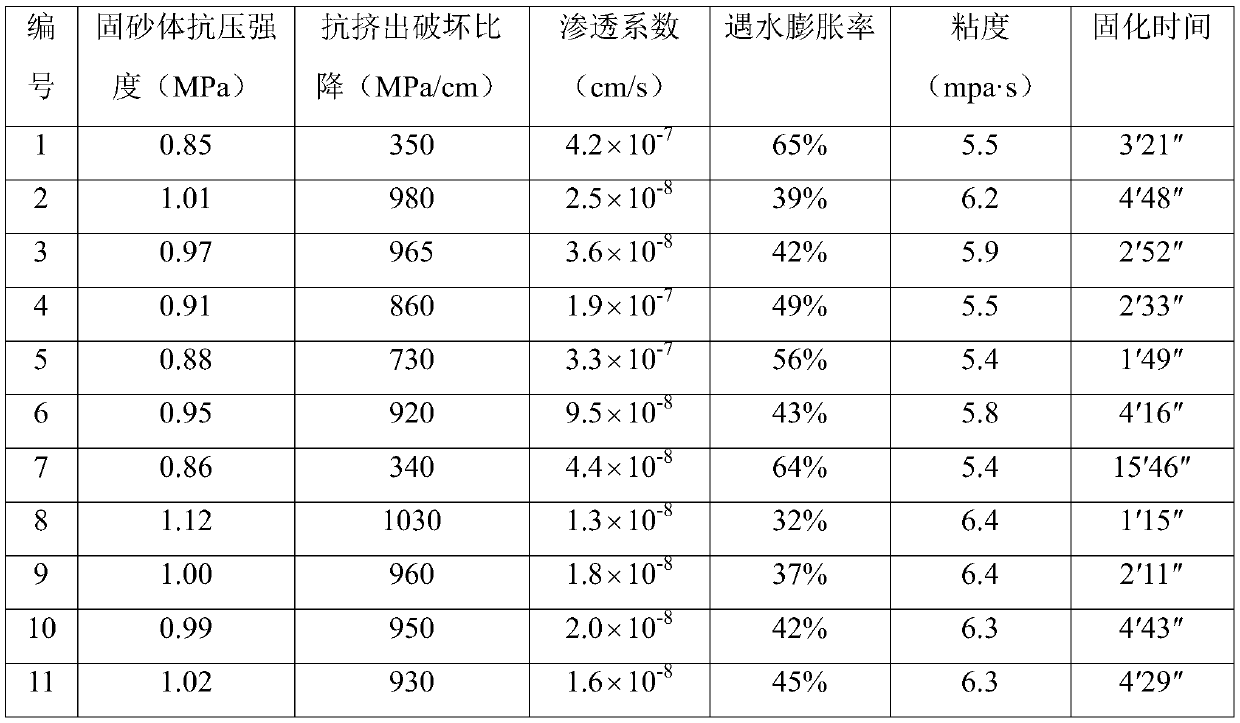

Examples

Embodiment 1

[0048] Prepare environment-friendly acrylate composite grouting material according to the following proportions:

[0049] Component A (by weight fraction): 6 parts of magnesium acrylate, 8 parts of calcium acrylate, 16 parts of copper acrylate, 4.8 parts of polyethylene glycol diallyl ether, 1.2 parts of ethoxylated bisphenol A diallyl ether, 50 parts of water;

[0050] Component B (by weight fraction): 3 parts of triethylenediamine, 1 part of ammonium persulfate, 3 parts of nano silicon dioxide, 0.02 part of sodium α-alkenyl sulfonate, 0.02 part of alkyl polyglycoside, iron chloride Potassium 0 parts, water 90 parts.

Embodiment 2

[0052] Prepare environment-friendly acrylate composite grouting material according to the following proportions:

[0053] Component A (by weight fraction): 8 parts of magnesium acrylate, 10 parts of calcium acrylate, 22 parts of copper acrylate, 4.8 parts of polyethylene glycol diallyl ether, 1.2 parts of ethoxylated bisphenol A diallyl ether, 50 parts of water;

[0054] Component B (by weight fraction): 3 parts of triethylenediamine, 1 part of ammonium persulfate, 3 parts of nano silicon dioxide, 0.02 part of sodium α-alkenyl sulfonate, 0.02 part of alkyl polyglycoside, iron chloride Potassium 0 parts, water 90 parts.

Embodiment 3

[0056] Prepare environment-friendly acrylate composite grouting material according to the following proportions:

[0057] Component A (by weight fraction): 6 parts of magnesium acrylate, 8 parts of calcium acrylate, 16 parts of copper acrylate, 8 parts of polyethylene glycol diallyl ether, 2 parts of ethoxylated bisphenol A diallyl ether, 50 parts of water;

[0058] Component B (by weight fraction): 3 parts of triethylenediamine, 1 part of ammonium persulfate, 3 parts of nano silicon dioxide, 0.02 part of sodium α-alkenyl sulfonate, 0.02 part of alkyl polyglycoside, iron chloride Potassium 0 parts, water 90 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| osmotic coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com