Smelting device and smelting method for electronic scraps

A technology of electronic waste and smelting equipment, applied in the direction of improving process efficiency, etc., can solve problems such as environmental pollution, overall backward technology, and low level of chemical method equipment, and achieve the effects of improving smelting efficiency, saving fuel, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

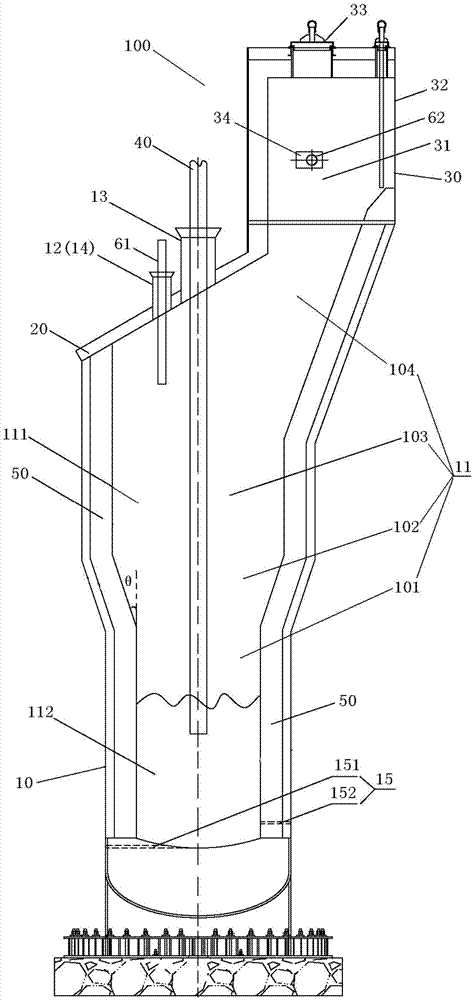

[0030] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

[0031] The electronic waste smelting device 100 according to the embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

[0032] refer to figure 1 As shown, the electronic scrap smelting device 100 according to the embodiment of the present invention may include a furnace body 10 , a furnace roof 20 , a secondary combustion chamber 30 and a spray gun 40 .

[0033] A furnace 11 may be defined inside the furnace body 10, and the furnace 11 may have an open upper end, that is, the upper end of the furnace 11 is open. The furnace 11 may include a gas phase zone 111 and a reaction zone 112 , and the gas pha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com