Horizontal barrel-plating production line capable of improving efficiency

A production line and barrel plating technology, applied in the direction of electrolysis process, electrolysis components, etc., can solve problems such as poor contact of cleaning bath plating solution, unsatisfactory design of barrel plating production line, and easy splashing of plating solution on conductors, etc. Ideal design, saving manpower and material resources, and improving the effect of equipment cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

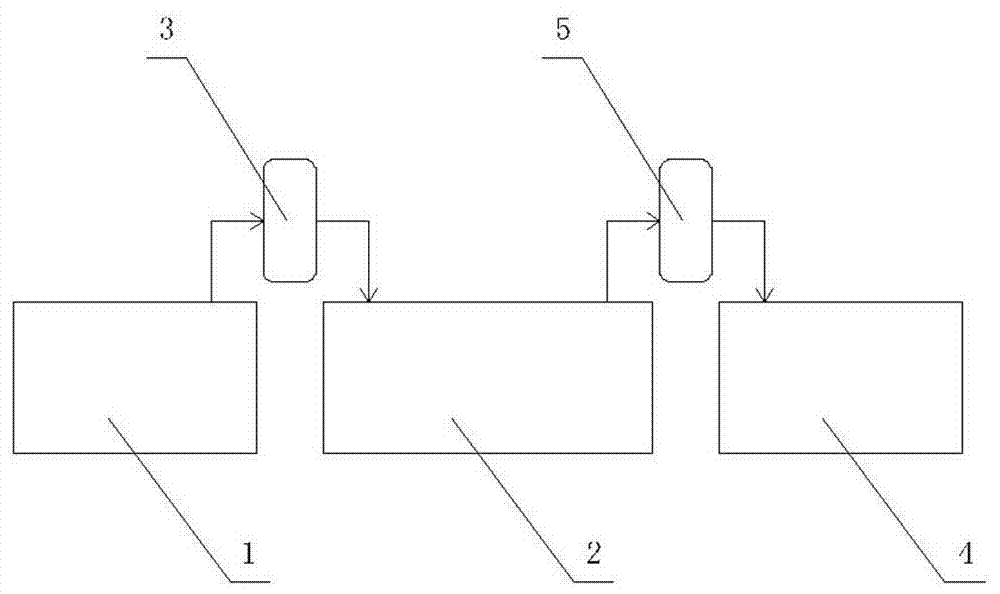

[0025] Refer to attached figure 1 , figure 2 , Figure 4 and Figure 7 . A horizontal barrel plating production line with improved efficiency, comprising a degreasing pool 1, a barrel plating pool 2, a first lifting mechanism 3 for transferring the drum in the degreasing pool 1 to the barrel plating pool 2, a cleaning pool 4, and a barrel plating pool 2 The inner drum is transferred to the second lifting mechanism 5 in the cleaning tank 4 .

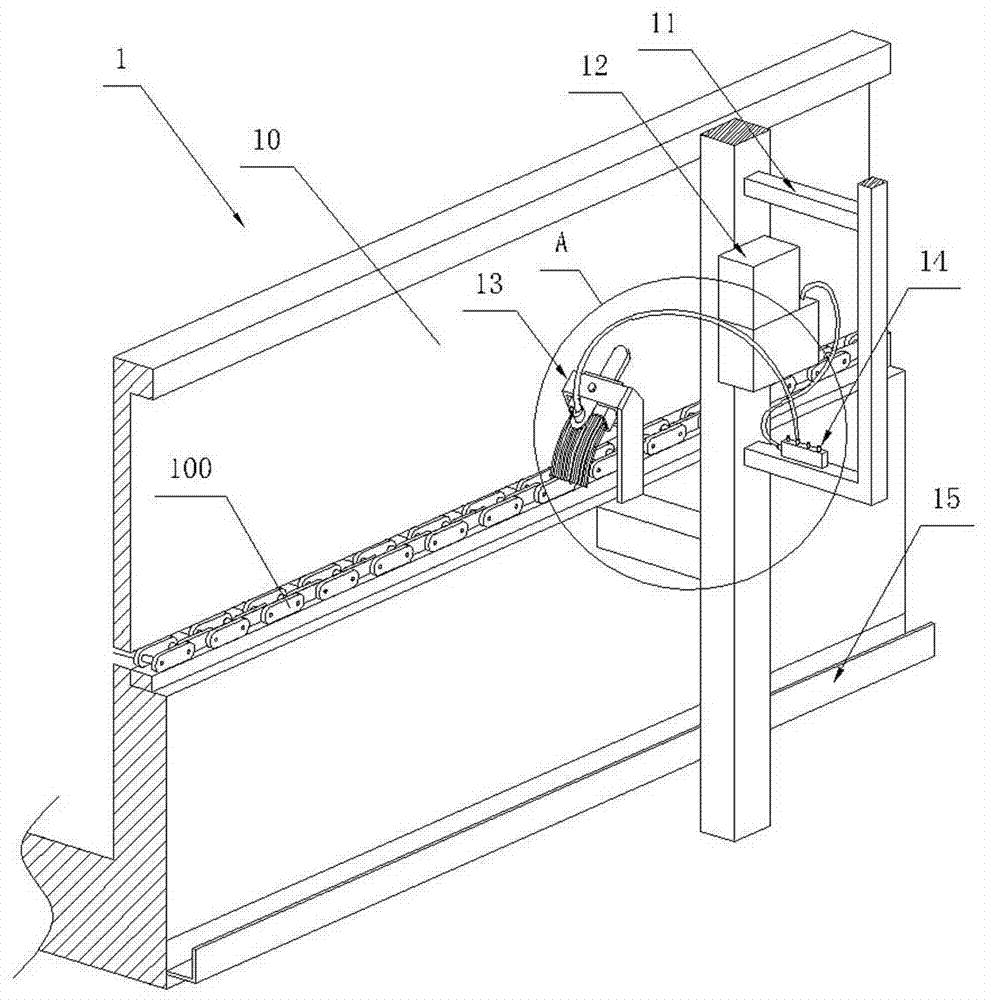

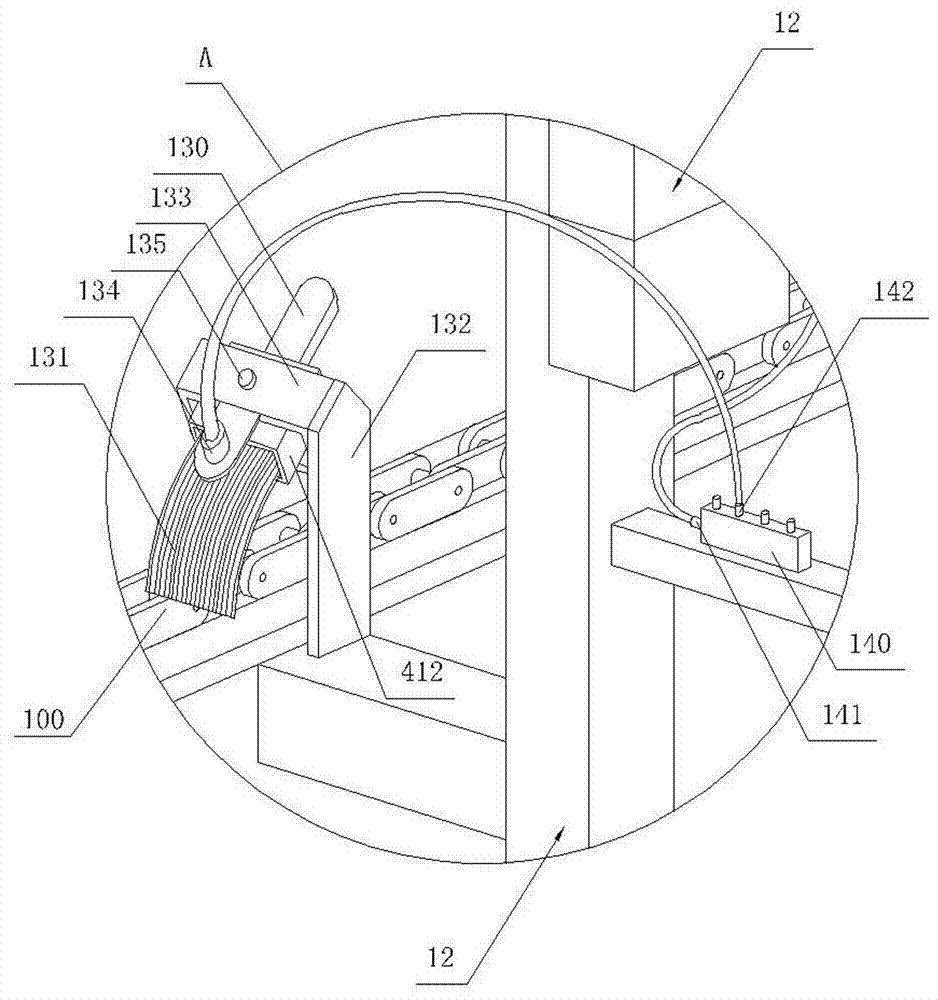

[0026] Refer to attached figure 2 and image 3 . The degreasing tank 1 comprises a degreasing tank body, a fixed frame 11 fixedly installed on the outer wall 10 of the degreasing tank body, and an oil supply mechanism 12 and a brushing mechanism 13 installed on the fixed frame 11. The mechanism 12 supplies oil to the brushing mechanism 13 through an oil guide mechanism 14, and the brushing mechanism 13 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com