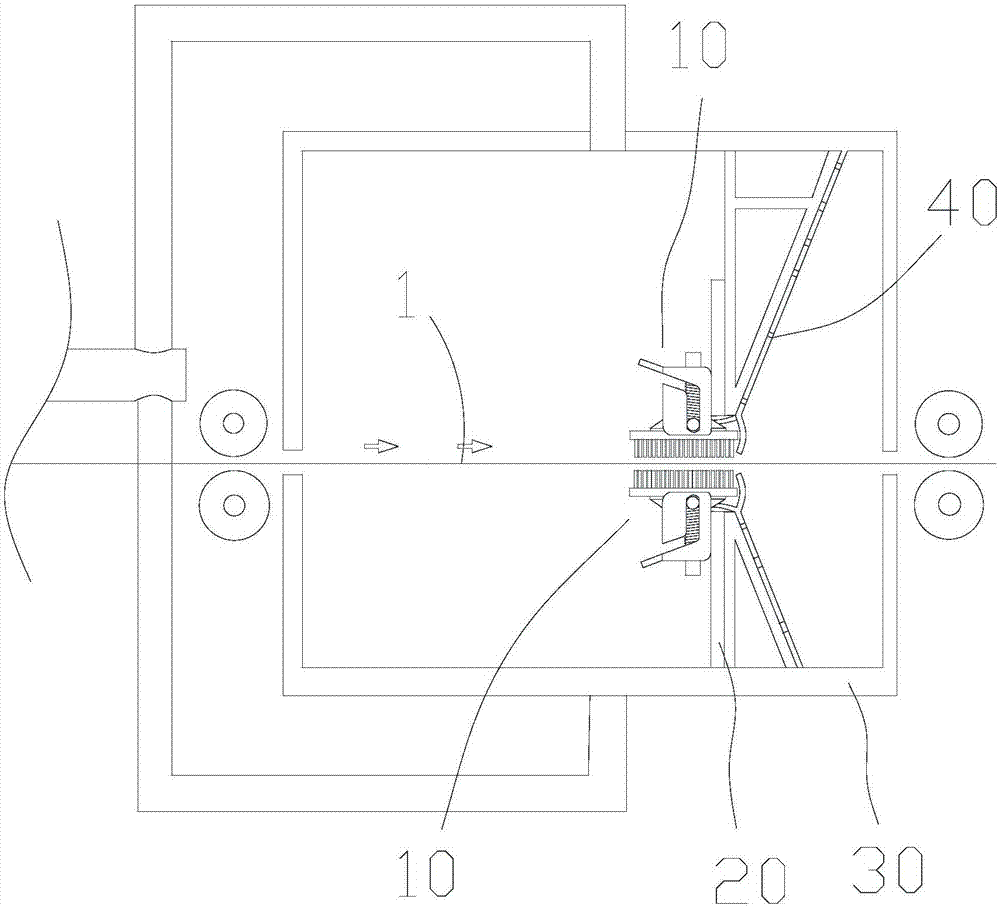

Fluff treatment device for lint manufacturing

A processing device and fluff technology, applied in the direction of floating yarn, etc., can solve problems such as difficult to clean fluff, fluff flying, and difficulty in disassembling brushes, etc., and achieve the effect of increasing thickness range, increasing usability, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

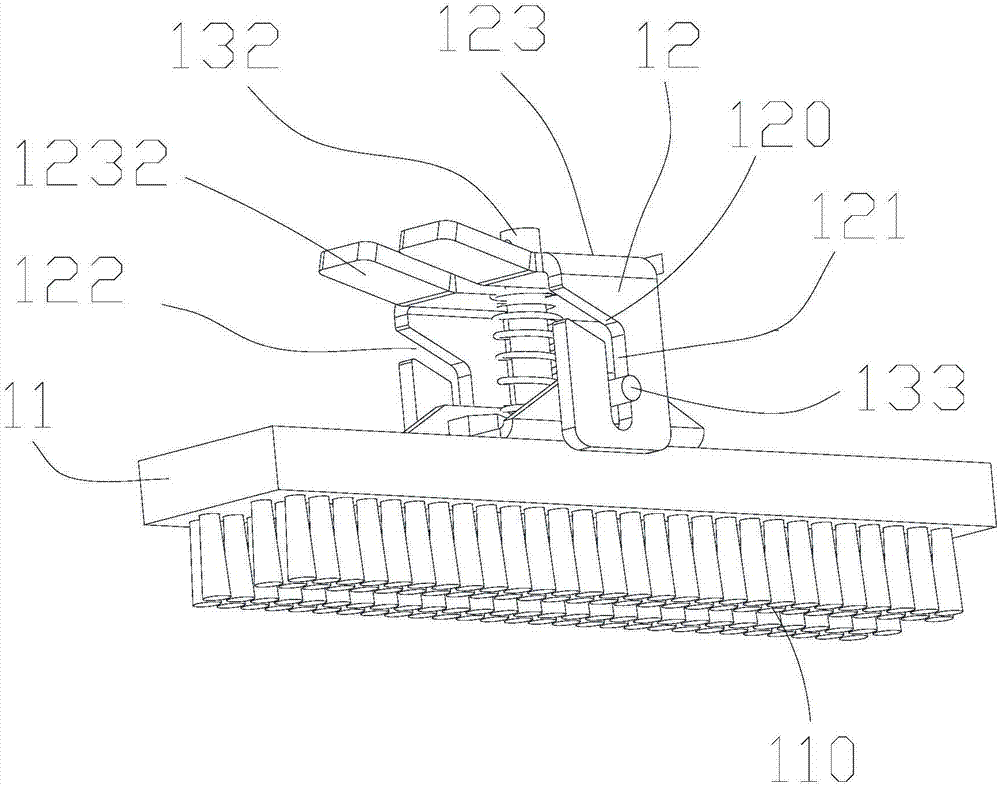

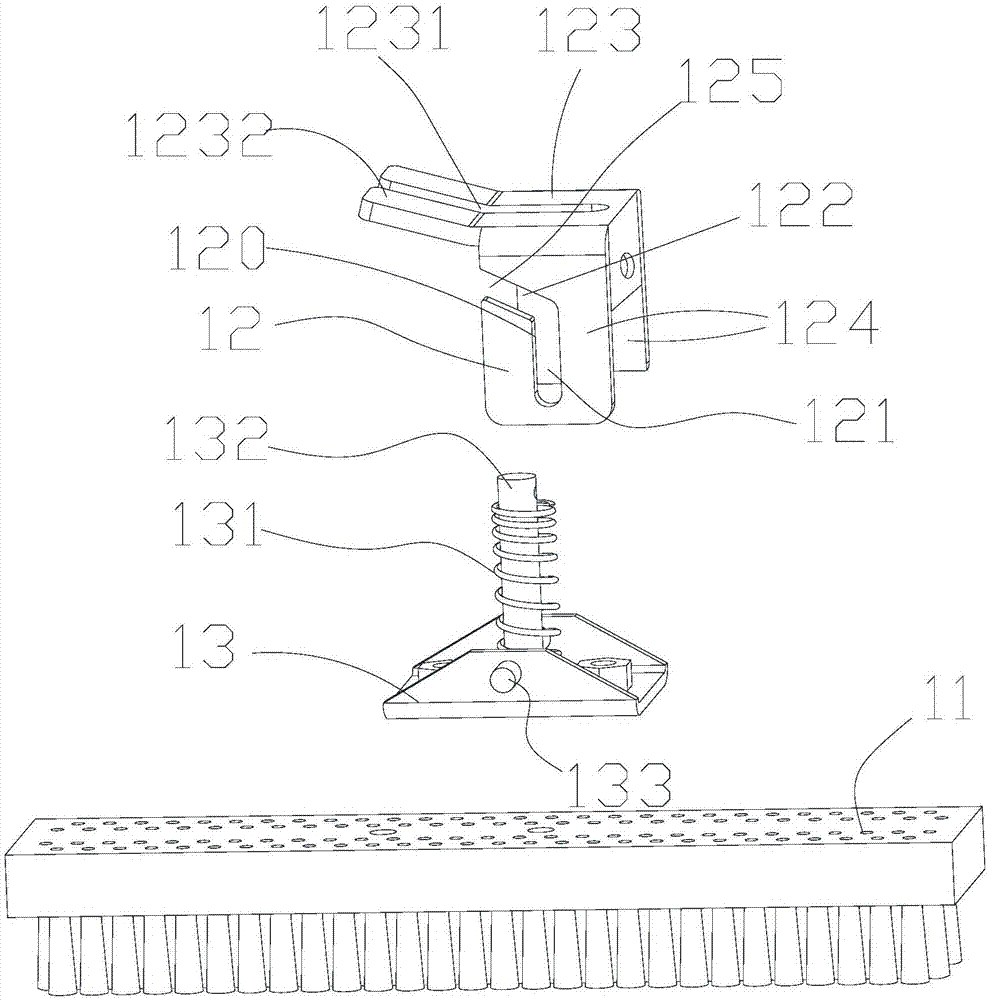

[0018] A fluff processing device for flannelette manufacture, such as figure 2 with image 3 As shown, it includes a brush mounting frame 12 fixed on the fixed frame 20 and a brush 11 installed on the brush mounting frame 12, and one side of the brush 11 has a The bristle portion 110 in contact with the surface, the brush installation frame 12 has two ear plates 124 arranged in parallel, the two ear plates 124 are symmetrically provided with strip mounting holes 120, one end side of the strip mounting holes 120 An opening 125 is opened to form an open strip-shaped mounting hole. A mounting member 13 is fixed on the side of the brush 11 facing away from the bristle portion 110. Two trunnions 133 are symmetrically arranged on the mounting member 13. The two trunnions 133 are arranged symmetrically. The trunnions 133 are respectively placed in the two-shaped mounting holes 120, and a spring 131 is arranged between the brush mounting bracket 12 and the mounting member 13, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com