Pan head cross self-drilling screw and processing process thereof

A technology of drilling tail screws and pan heads, which is applied in the direction of screws, nuts, bolts, etc., which can solve the problems of reducing connection strength and connection life, high temperature resistance of drilling tail screws, time-consuming and labor-intensive problems, etc., to improve anti-embroidery performance and drill holes Efficient, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

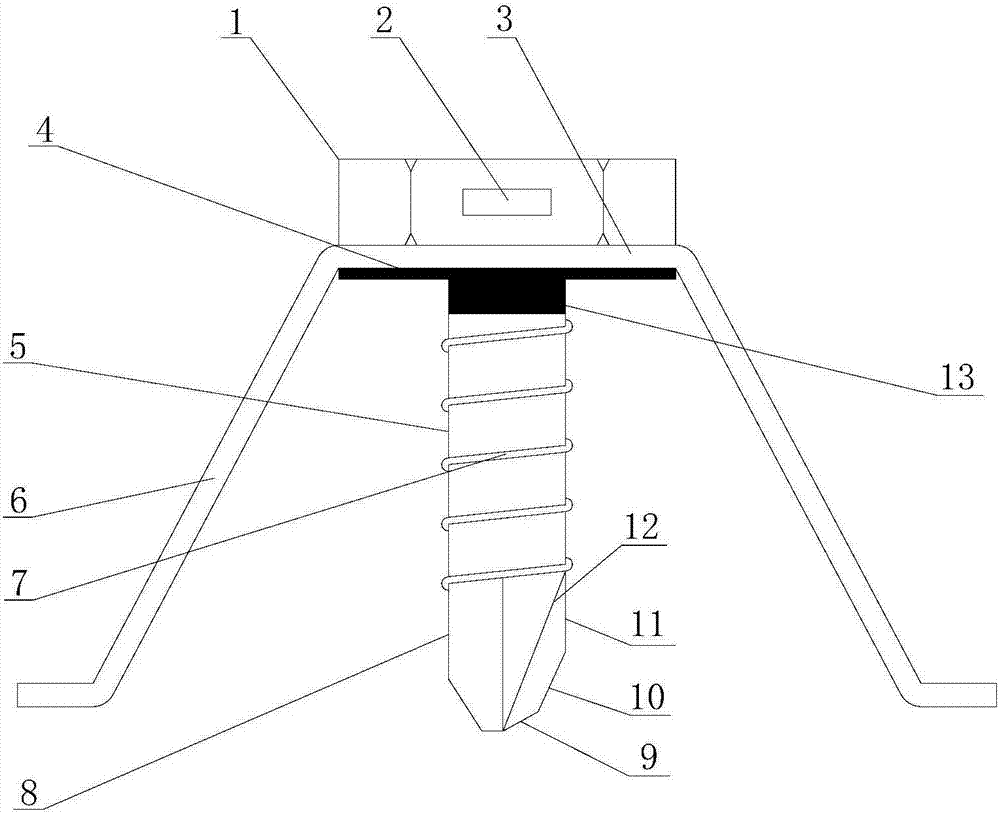

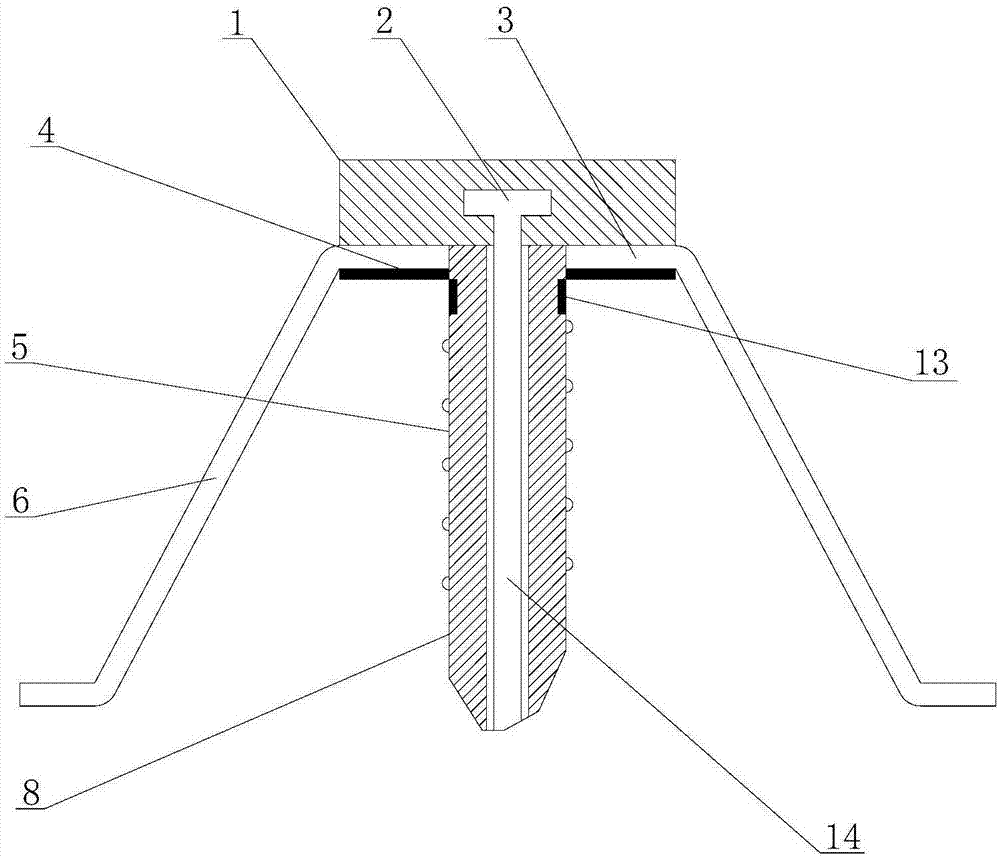

[0051] A kind of pan head cross-drilling screw of this embodiment, such as figure 1 with 2 As shown, it includes pan head 1, support gasket 3, screw rod 5 and drill tail 8. Pan head 1 is in the shape of a hexagonal column. A chip discharge port 2 is provided on the side of pan head 1, and a support pad is provided at the lower end of pan head 1. Sheet 3, the lower surface of the support gasket 3 is covered with the first water-expandable waterstop 4, the upper end of the screw rod 5 runs through the support gasket 3 and is fixedly connected to the lower end of the pan head 1, and the screw rod 5 is provided with an external thread 7, and the screw rod 5 The lower end is fixedly connected with the drill tail 8, and the middle part of the screw rod 5 is provided with a through hole 14 from top to bottom, the upper end of the through hole 14 communicates with the chip discharge port 2, and the lower end of the through hole 14 extends to the lowermost end of the screw tail 8, and ...

Embodiment 2

[0077] A kind of pan head cross-drilling screw of this embodiment, such as figure 1 with 2 As shown, it includes pan head 1, support gasket 3, screw rod 5 and drill tail 8. Pan head 1 is in the shape of a hexagonal column. A chip discharge port 2 is provided on the side of pan head 1, and a support pad is provided at the lower end of pan head 1. Sheet 3, the lower surface of the support gasket 3 is covered with the first water-expandable waterstop 4, the upper end of the screw rod 5 runs through the support gasket 3 and is fixedly connected to the lower end of the pan head 1, and the screw rod 5 is provided with an external thread 7, and the screw rod 5 The lower end is fixedly connected with the drill tail 8, and the middle part of the screw rod 5 is provided with a through hole 14 from top to bottom, the upper end of the through hole 14 communicates with the chip discharge port 2, and the lower end of the through hole 14 extends to the lowermost end of the screw tail 8, and ...

Embodiment 3

[0103] A kind of pan head cross-drilling screw of this embodiment, such as figure 1 with 2 As shown, it includes pan head 1, support gasket 3, screw rod 5 and drill tail 8. Pan head 1 is in the shape of a hexagonal column. A chip discharge port 2 is provided on the side of pan head 1, and a support pad is provided at the lower end of pan head 1. Sheet 3, the lower surface of the support gasket 3 is covered with the first water-expandable waterstop 4, the upper end of the screw rod 5 runs through the support gasket 3 and is fixedly connected to the lower end of the pan head 1, and the screw rod 5 is provided with an external thread 7, and the screw rod 5 The lower end is fixedly connected with the drill tail 8, and the middle part of the screw rod 5 is provided with a through hole 14 from top to bottom, the upper end of the through hole 14 communicates with the chip discharge port 2, and the lower end of the through hole 14 extends to the lowermost end of the screw tail 8, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com