Drilling tools and drill bits

A technology for drilling tools and drill bits, which is applied in the field of drilling tools and drill bits, can solve the problems of chip removal efficiency, the difficulty of supporting the strength of the blade, and achieve the effects of being conducive to discharge, strong anti-deformation ability, and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

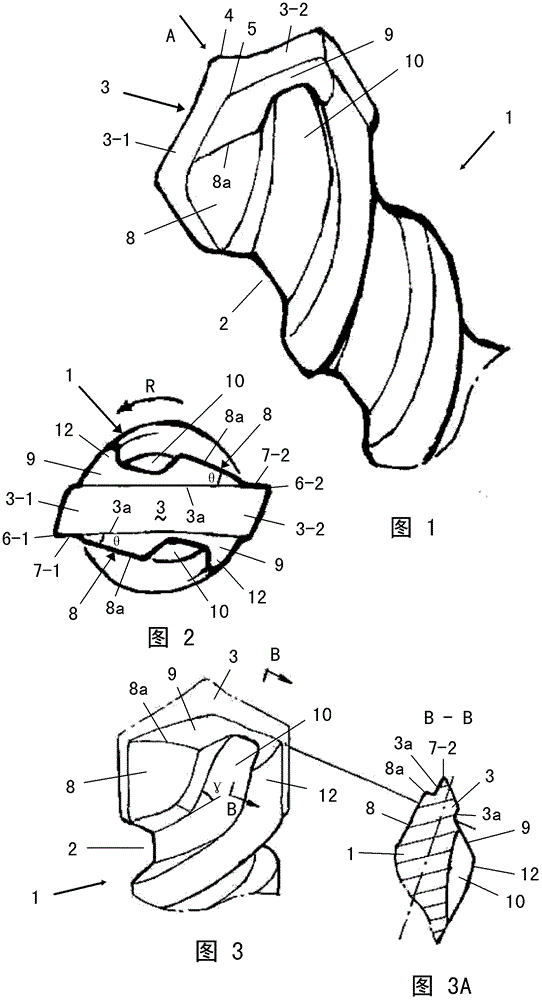

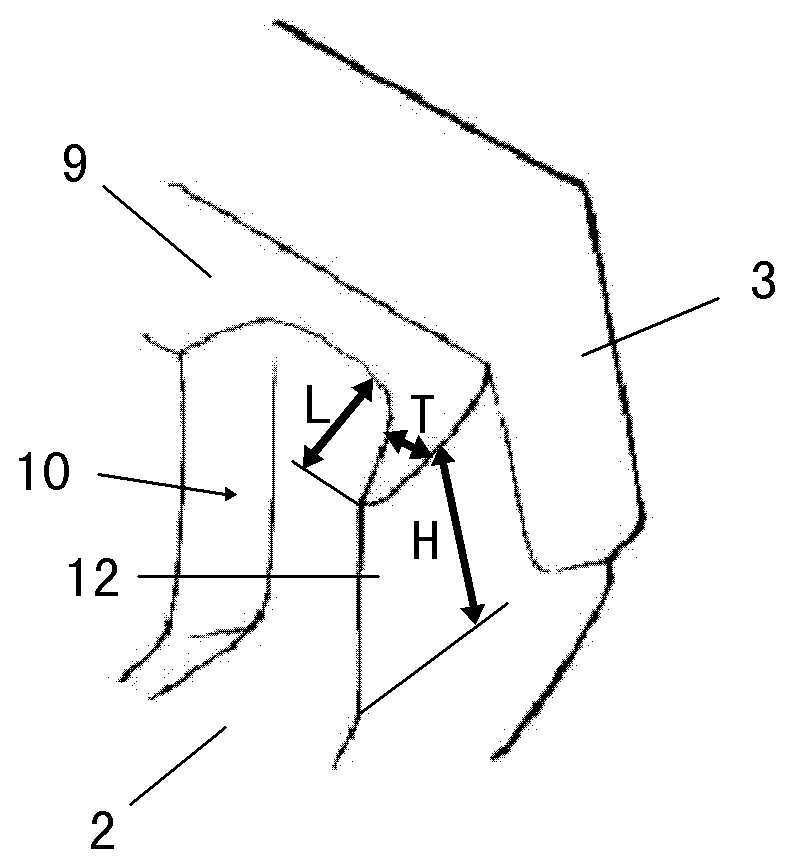

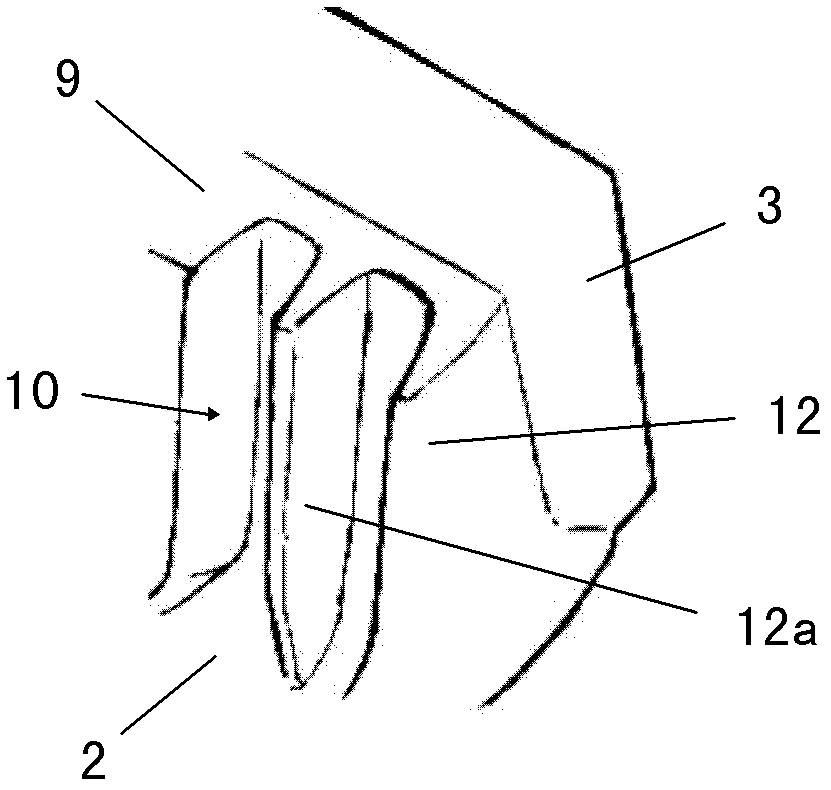

[0028] The present invention relates to improvements to the distal (tip) portion of drill bits. The present invention is particularly applicable to drills with carbide inserts at the distal end, such as percussion drills, masonry drills, glass drills, multifunctional drills, and the like. The following description is mainly directed to drills with carbide inserts, however, it should be pointed out that the basic principles of the invention can also be applied to drills without carbide inserts. Therefore, the present invention is applicable to various drill bits and corresponding drilling tools (such as electric drilling tools, especially portable electric drilling tools).

[0029] In the present application, the so-called "distal side" refers to the direction toward the drill part to be drilled into the processing object, and "near side" refers to the direction toward the drill part to be clamped in the electric drilling tool body.

[0030] As is well known in the art, a dril...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com