UF6 gas leakage detecting, sample and monitoring device and method thereof

A sampling device and gas technology, applied in the field of UF6 gas leak detection sampling monitoring device, can solve the problems of observation and monitoring, UF6 leakage failure, etc., and achieve the effect of preventing serious accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In the following, in conjunction with the drawings and embodiments, a UF of the present invention 6 The gas leak detection sampling monitoring device and method are described in detail.

[0021] When the gas uranium hexafluoride encounters water, the following reactions occur:

[0022] UF 6 +H 2 O→UO 2 F 2 +4HF

[0023] The reaction will be completed in a very short time, and a large number of positive and negative ions are generated in the solution, which will inevitably lead to a sharp rise in the conductivity of water.

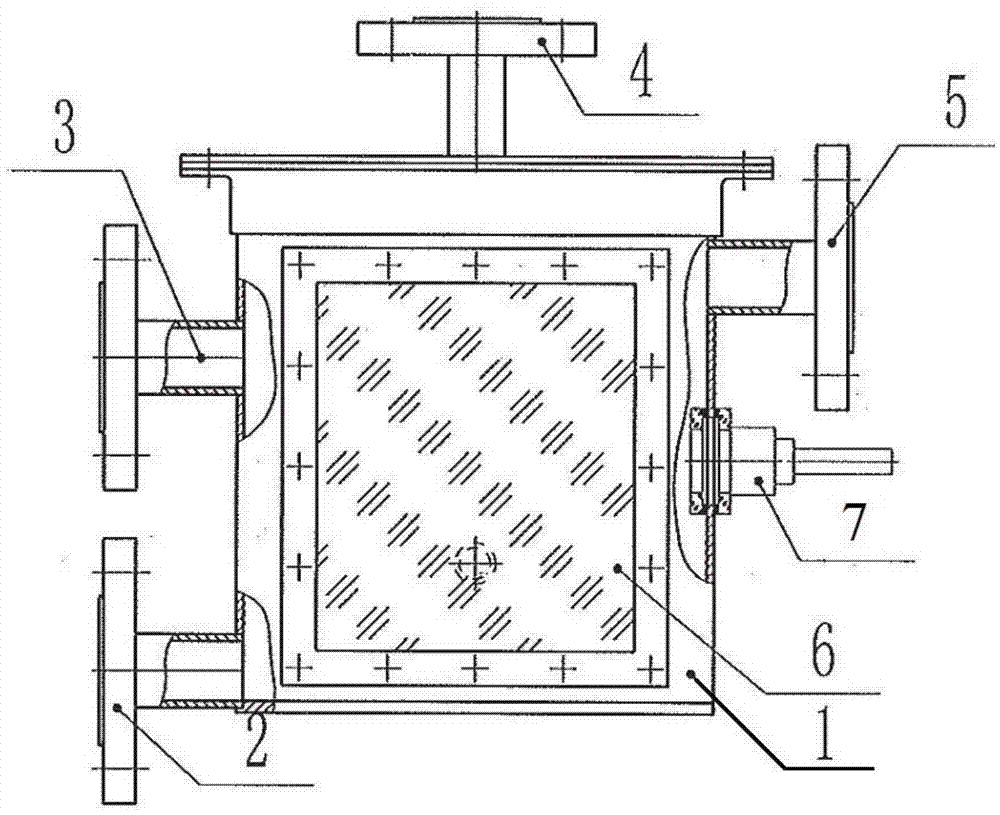

[0024] UF of the present invention 6 Gas leak detection sampling device such as figure 1 As shown, it includes: the tank body 1, the air inlet 2, the overflow port 3, the air outlet 4, the deionized water injection port 5, the organic glass window 6 and the conductivity probe 7.

[0025] The tank body 1 is a cylindrical tank body, the air inlet 2 is provided at the lower part of the tank body 1, and the air inlet 2 is connected to the UF 6 The gas sampling pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com