Multi-ported valve control function test method

A technology of control function and test method, which is applied in the direction of machine/structural component testing, measuring electricity, measuring devices, etc., and can solve problems affecting the normal operation of diesel engines and complex structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

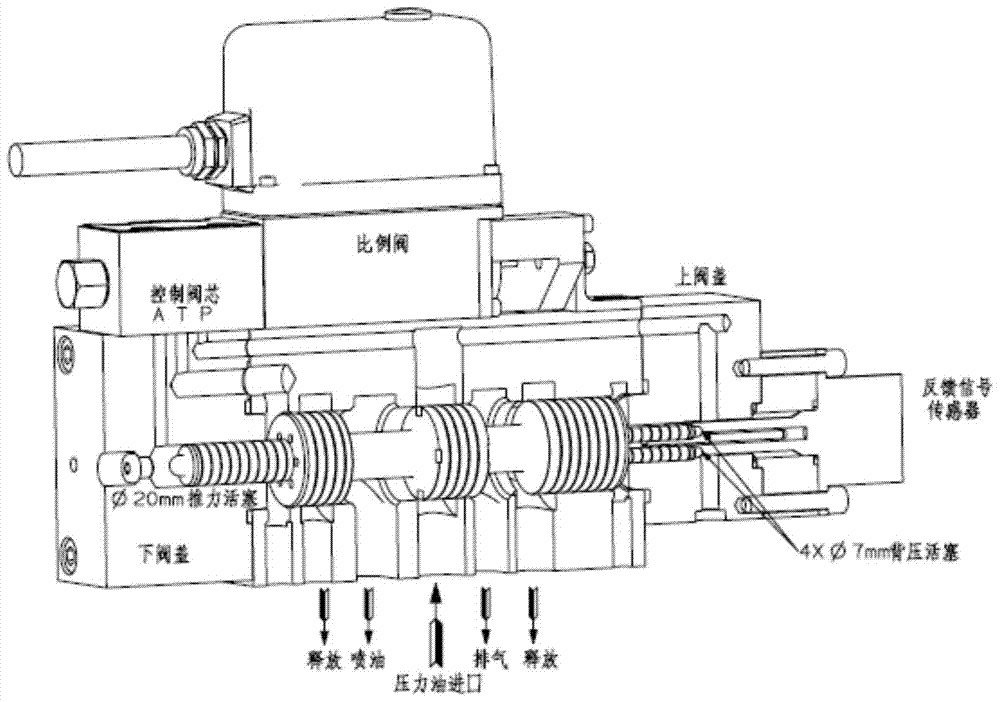

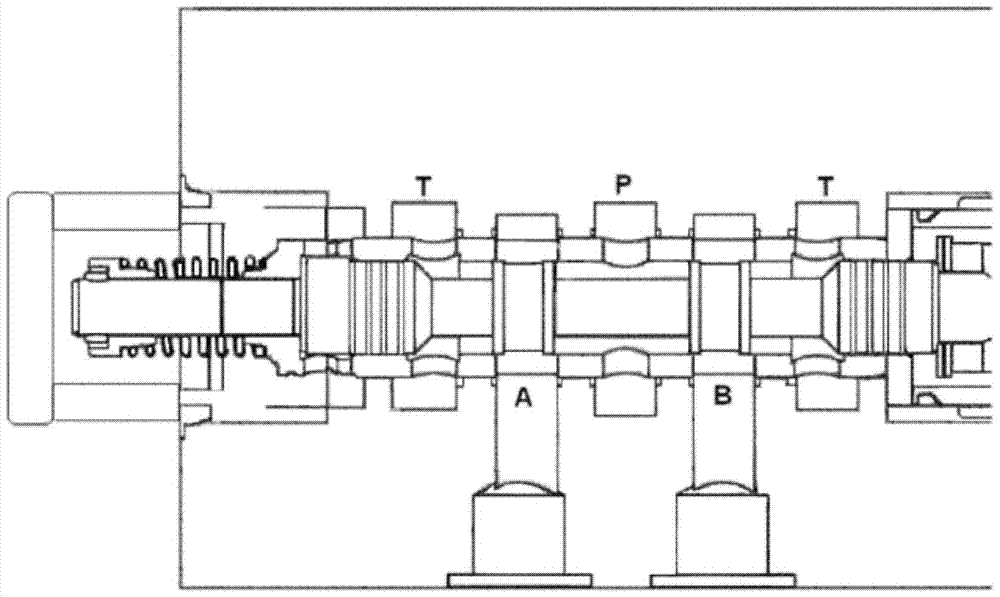

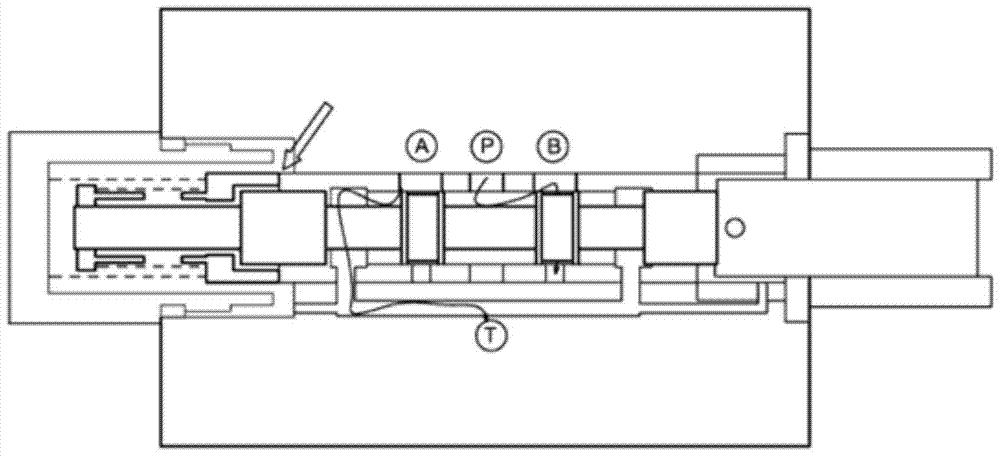

[0019] Embodiments of the present invention are described below with reference to the drawings, in which like parts are denoted by like reference numerals.

[0020] In the present invention, when a current signal is input to the proportional valve, the internal spool of the proportional valve will move, and the proportional valve itself will feed back a voltage signal. By comparing the signal input and output values and observing the position of the spool, it is judged whether the control function of the proportional valve is normal.

[0021] The equipment required for the test is: DC stabilized power supply 4; adjustable signal generator 2, which can provide at least 4mA-20mA output; voltage testing device 3, such as voltmeter and multimeter. The devices can be connected via an intermediate junction box 5 .

[0022] The multi-way valve control function testing method of the present invention comprises the following steps:

[0023] S1: if Figure 7 The proportional valve 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com