Protective film of photosensitive dry film

A technology of photosensitive dry film and protective film, which is applied in the direction of photosensitive materials, optics, and optical components used in optomechanical equipment. It can solve the problems of lamination failure, insufficient rigidity, bamboo-shaped annular protrusions, etc., and achieve high fog Accuracy and hiding power, improve quality, and prevent slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to facilitate the understanding of those skilled in the art, the invention will be further described below in conjunction with the accompanying drawings.

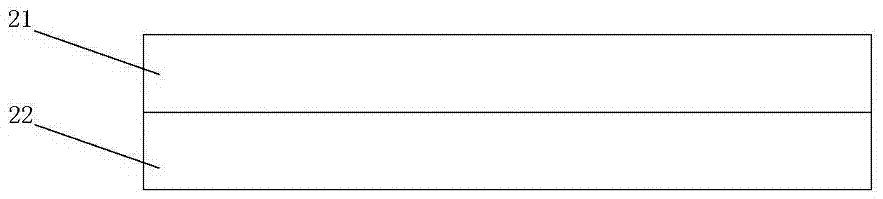

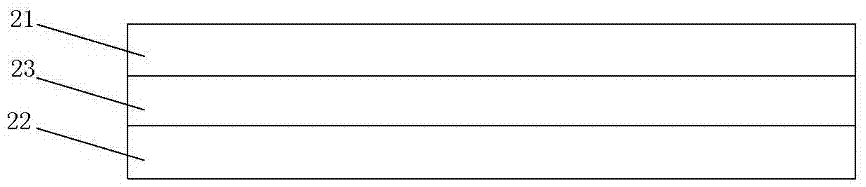

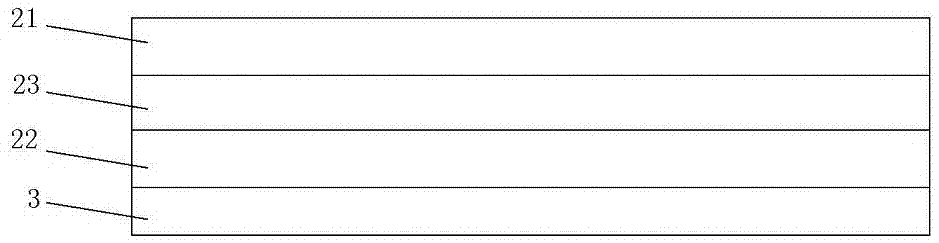

[0023] as attached figure 1 , 2 Shown in and 3, the present invention discloses a protective film of a photosensitive dry film, comprising a film body, the film body comprising a matte layer 21 with a matte surface and a glossy layer 22 with a glossy surface; the glossy layer The roughness Ra of 22 is 0-0.15 microns, the surface energy is 0-25 dynes / cm, and the release force is 0-2000 grams; the roughness Ra of the matte surface layer 21 is greater than 0.15 microns, and the surface energy is greater than 25 dynes / cm cm, the release force is greater than 2000 grams. The roughness of the glossy layer refers to the roughness of the smooth surface where the glossy layer is located, and the roughness of the matte layer refers to the roughness of the matte surface where the matte layer is located. The glossy s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| release force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com