Wafer jacking device and jacking method thereof

A technology for lifting devices and wafers, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve problems such as wafer pollution and wafer offset, and achieve pollution-free, space-saving, gentle and stable lifting processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

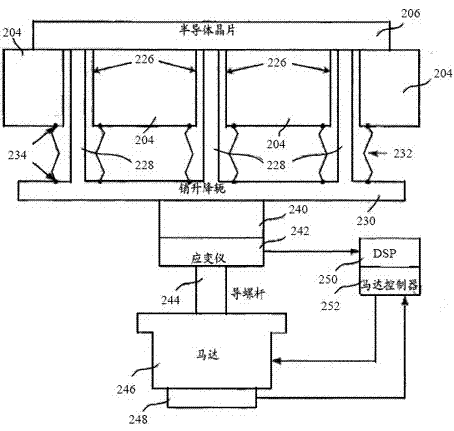

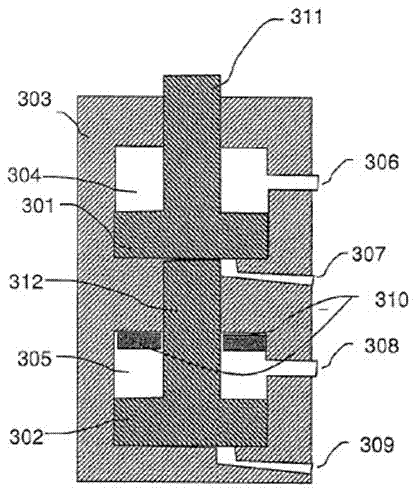

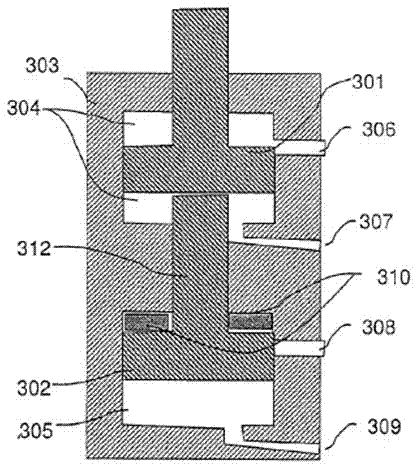

[0050] based on the following Figure 4 ~ Figure 8B , specifically explain the preferred embodiment of the present invention.

[0051] Such as Figure 4 As shown, the present invention provides a wafer jacking device, which is arranged in the plasma etching chamber. An equipment tray 3 is arranged in the etching chamber, and an electrostatic chuck 2 is arranged on the equipment tray 3. The wafer is adsorbed on the electrostatic chuck 2, and the static electricity Both the suction cup 2 and the equipment tray 3 have a number of through holes, and the through holes on the equipment tray 3 and the through holes on the electrostatic chuck 2 form a guiding channel 21. The wafer lifting device includes:

[0052] A plurality of first lifting components, which are arranged under the wafer through the guide channel 21, are used to complete the first lifting stage, and lift the wafer to a distance of 0.5 to 3 mm from the electrostatic chuck to separate the wafer from the electrostatic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com