OLED (Organic Light-Emitting Diode) display panel packaging structure and packaging method

A display panel and packaging structure technology, which is applied in the field of OLED display panels, can solve the problems of package failure, poor user experience, screen wiring and circuit damage, etc., to improve the packaging effect, realize narrow frame display, reduce Effect of border size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and examples.

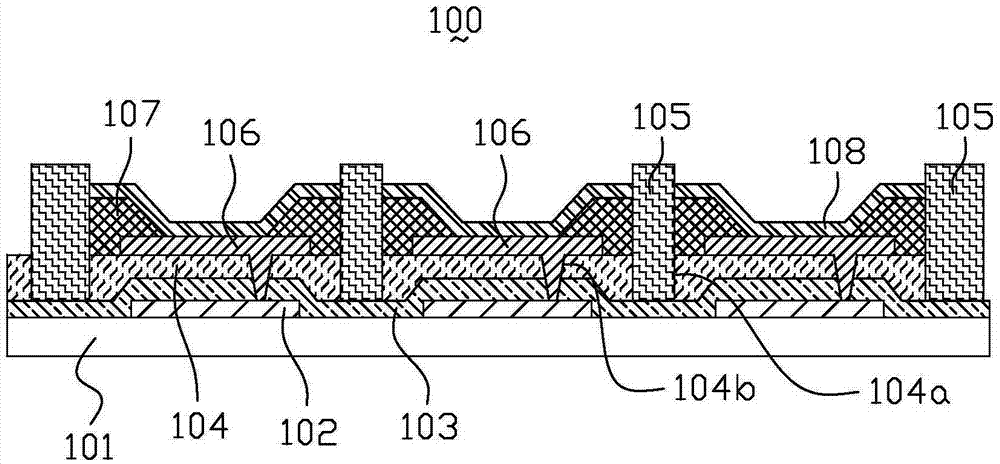

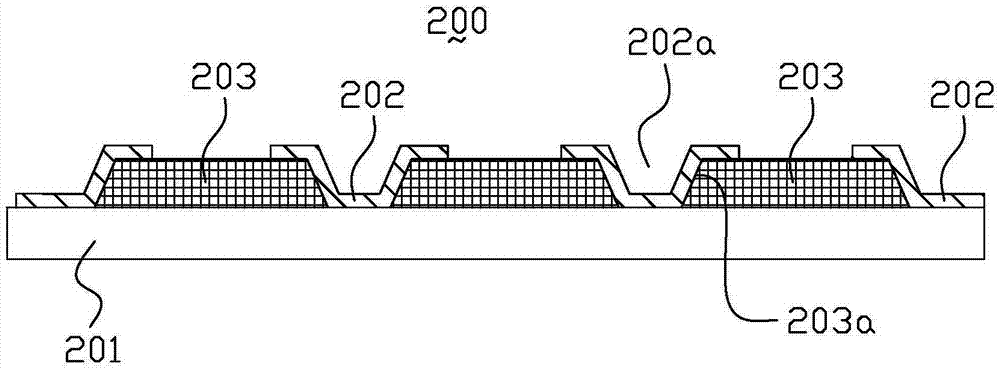

[0028] An embodiment of the present invention provides a packaging structure of an OLED display panel, which includes a substrate 100 and a cover 200, and is formed by two parts of the substrate 100 and the cover 200, respectively as follows figure 1 and figure 2 shown.

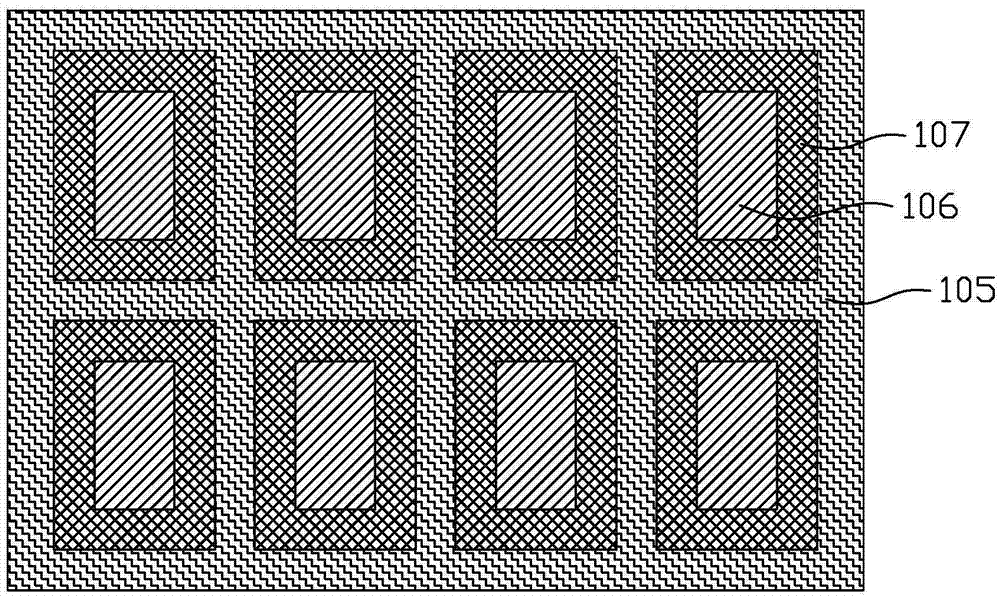

[0029] Please refer to figure 1 , the substrate 100 includes a first substrate 101, a plurality of pixel regions are formed on the first substrate 101, an OLED device 108 and a pixel circuit 102 for driving the OLED device 108 are formed in each pixel region, and the OLED device 108 is located in the pixel circuit 102 above. The substrate 100 forms a metal isolation wall 105 around the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com