Spraying control method for spraying manipulator

A control method and manipulator technology, applied in the direction of spraying device, etc., can solve the problems of uneven spraying, waste of spraying paint, etc., and achieve the effect of even spraying, saving spraying time and manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

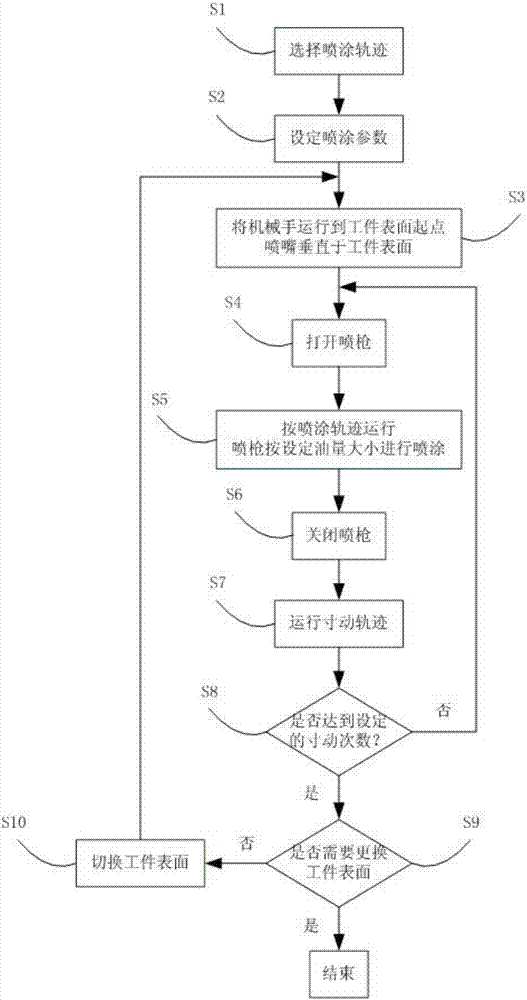

[0039] A spraying control method of a spraying manipulator, such as figure 1 shown, including the following steps:

[0040] S1: Select the spraying trajectory according to the surface of the workpiece to be sprayed;

[0041] S2: Set the spraying parameters;

[0042] S3: Run the manipulator to the starting point of the workpiece surface, and the nozzle of the manipulator spray gun is always perpendicular to the workpiece surface;

[0043] S4: open the spray gun;

[0044] S5: The spray gun runs equidistantly along the surface of the workpiece according to the spray trajectory selected in step S1, and sprays according to the set oil volume, that is, the proportional valve of the spray gun is controlled by the analog voltage output, so as to control the spray gun according to the set oil volume to spray;

[0045] S6: close the spray gun;

[0046] S7: Run the inching track;

[0047] S8: Judging whether the set number of times of inching has been reached, if yes, go to step S9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com