Formaldehyde-free plywood of full-symmetrical structure

A plywood, fully symmetrical technology, used in the bonding of wooden veneers, adhesive application devices, manufacturing tools, etc., can solve problems such as formaldehyde release and plywood deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

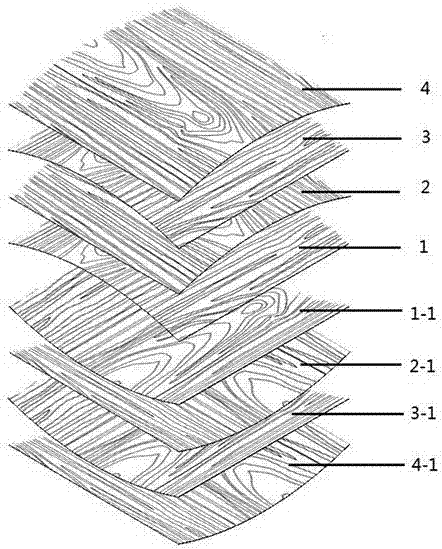

[0016] Embodiment one: if figure 1 As shown, from the center line of the plywood to both sides, layers 1 and 1-1, 2 and 2-1, 3 and 3-1, 4 and 4-1 are respectively arranged, among which 1 and 1-1 are made of the same material and have the same thickness , the wood fibers are in the same direction, and the loose side of the rotary cut veneer is opposite. 2 and 2-1 have the same material, the same thickness, and the wood fibers are in the same direction, and the loose side of the rotary-cut veneer is opposite; the fiber directions of layer 2 and layer 1 are perpendicular to each other.

Embodiment 2

[0017] Embodiment two: if figure 2 As shown, from the center line of the plywood to both sides, layers 1 and 1-1, 2 and 2-1, 3 and 3-1, 4 and 4-1 are respectively arranged, among which 1 and 1-1 are made of the same material and have the same thickness , the wood fibers are in the same direction, and the tight sides of the rotary cut veneer are opposite. 2 and 2-1 have the same material, the same thickness, the wood fibers are in the same direction, and the tight surface of the rotary cut veneer is opposite; the fiber directions of layer 2 and layer 1 are perpendicular to each other.

Embodiment 3

[0018] Embodiment 3: From the center line of the plywood to both sides, layers 1 and 1-1 are made of the same material, have the same thickness, the wood fibers are in the same direction, and the tight surfaces of the rotary-cut veneers are opposite. 2 and 2-1 have the same material, the same thickness, and the wood fibers are in the same direction, and the loose side of the rotary-cut veneer is opposite; the fiber directions of layer 2 and layer 1 are perpendicular to each other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com