Integral window drilling tool

A window-opening sidetracking and integrated technology is applied in the field of oil drilling to achieve the effects of reducing milling, cost and tension.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

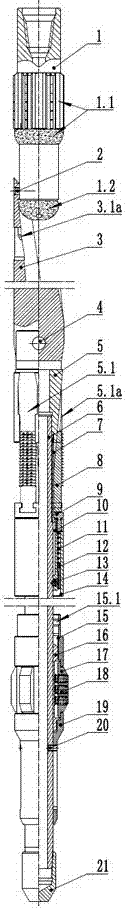

[0032] In order to overcome the problems of existing mechanical and hydraulic window tools, this embodiment provides a Figure 1 to Figure 4 The integrated fenestration sidetracking tool shown in the figure includes three parts: a fenestration sidetracking unit, a slip anchoring unit, and a friction steering unit connected sequentially from top to bottom;

[0033] The window sidetracking unit includes a milling cone 1 and a bevel 3, and the lower part of the milling cone 1 is connected to the upper part of the bevel 3 through a shear nail 2;

[0034] The slip anchoring unit includes a central shaft 6 inside and a slip 8 and a jacket 14 outside the upper part of the central shaft 6. The outer side of the slip 8 is provided with teeth, and the upper and lower ends of the slip 8 are respectively connected to the upper slips. Seat 5 and lower slip seat 9, the outer side of the upper slip seat 5 is provided with an inclined chute 5.1, the upper end of the slip 8 is nested in the in...

Embodiment 2

[0043] On the basis of Embodiment 1, this embodiment provides an integrated sidetracking tool for opening windows. In order to facilitate the lowering of the tool, a guide cone 21 is provided outside the lower end of the central shaft 6 .

[0044] The milling cone 1 has a two-stage structure, the middle part is a window repairing part 1.1, and the lower end is a window opening part 1.2. The two-stage milling cone can complete the window opening and repairing operation in one pass, and after the shear nails are cut off, the milling cone can directly act on the casing wall, reducing the milling of the milling cone on the guide bevel, shortening the milling time and reducing the It reduces the cost and helps to improve the window opening efficiency.

Embodiment 3

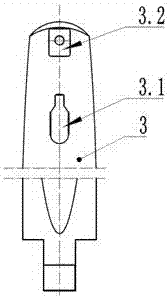

[0046] On the basis of Embodiment 2, this embodiment provides an integrated sidetracking tool for opening windows. The angle of the inclined surface of the leading inclined body 3 is 2-3°, and the upper part of the inclined surface of the leading inclined body 3 is provided with an inner cylindrical boss. 3.2, the shear nail 2 passes through the shear nail hole on the inner cylindrical boss 3.2 and is tightened with the threaded hole on the milling cone 1 . Ensure that the inner cylindrical surface of the inner cylindrical surface boss 3.2 is in close contact with the outer cylindrical surface of the milling cone 1. This design not only enhances the strength around the shear nail hole, but also reduces the tension on the shear nail 2. At the same time, it effectively makes the milling cone 1 acts directly on the casing wall, reducing the milling of the milling cone 1 for the guide bevel 3.

[0047] A salvage hole 3.1 is provided on the middle and upper part of the inclined sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com