Mine overall precise wind measurement sensor optimal arrangement method

A layout method and sensor technology, applied in mine/tunnel ventilation, mining equipment, earthwork drilling and mining, etc., can solve the problems of difficult accurate wind speed monitoring, low wind speed, and low sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

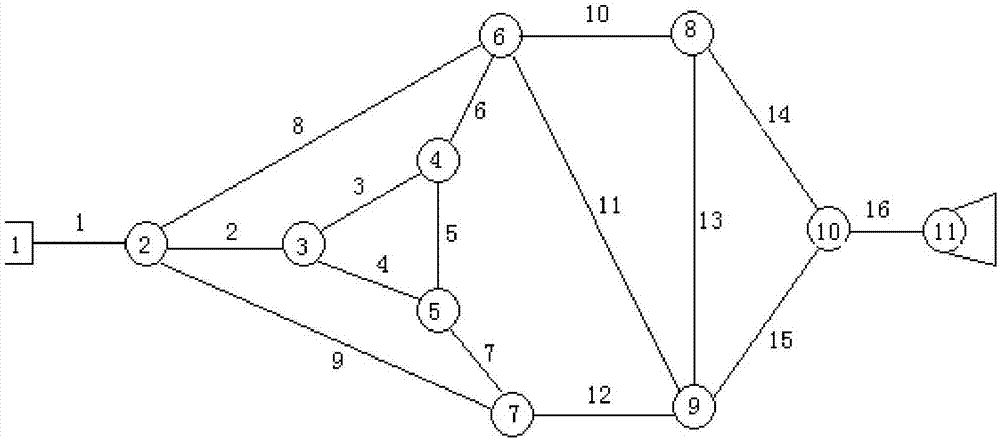

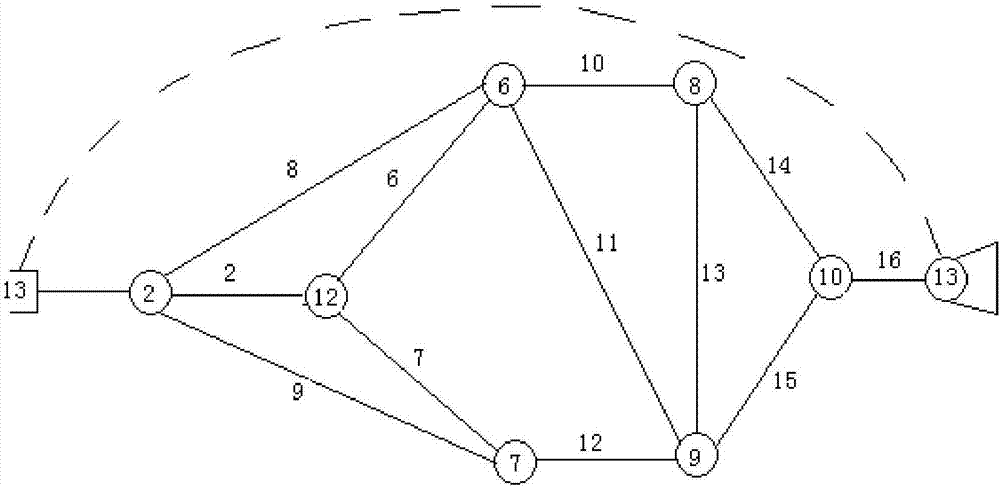

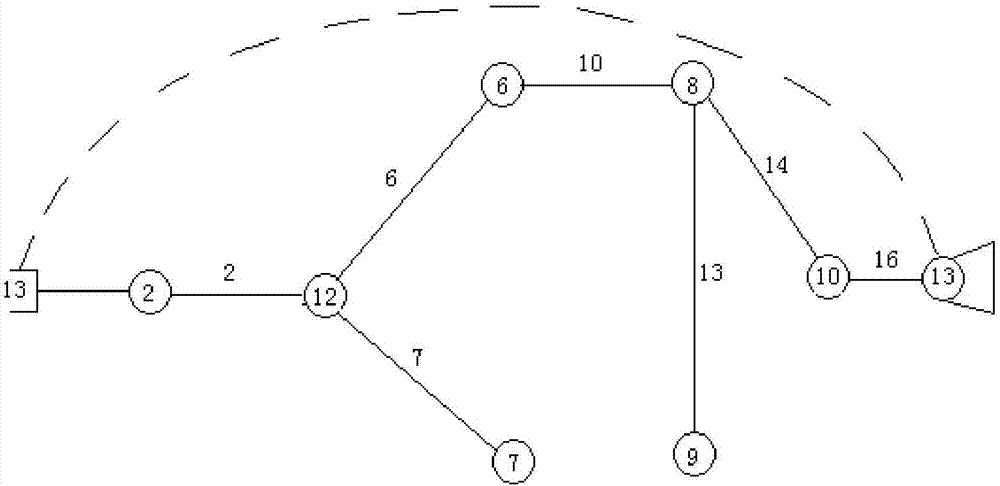

[0096] like figure 1 Shown is the network topology diagram of the mine ventilation system. Assumption figure 1 Among them, the air ducts 10, 11, and 12 are the air ducts where the mining face with large wind resistance changes; the air ducts 3, 4, and 5 are the natural air ducts of the air inlet area with basically constant wind resistance; 13 is the unmeasurable air duct where the wind speed sensor cannot be arranged; the air duct 16 is the air duct where the fan is located, and the working characteristic curve of the fan is:

[0097] P f =-0.09921Q2 +2.54271Q+4861.9637

[0098] Step 1, establish a complete mine ventilation system network topology diagram and number it, and obtain the numbered mine ventilation system network topology diagram G=(V, E), where V={1,2,3,4,5, 6,7,8,9,10,11} is the node set, E={1,2,3,4,5,6,7,8,9,10,11,12,13,14,15,16 } is the wind channel set. That is, in figure 1 There are 11 nodes and 16 air ducts in total.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com