Autoclaved aerated concrete block masonry performance detection method

A technology of concrete block and autoclaved aeration, which is applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, strength characteristics, etc. and other problems, to achieve the effect of improving the standardization of testing, filling the gaps in the industry, and facilitating the implementation of testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

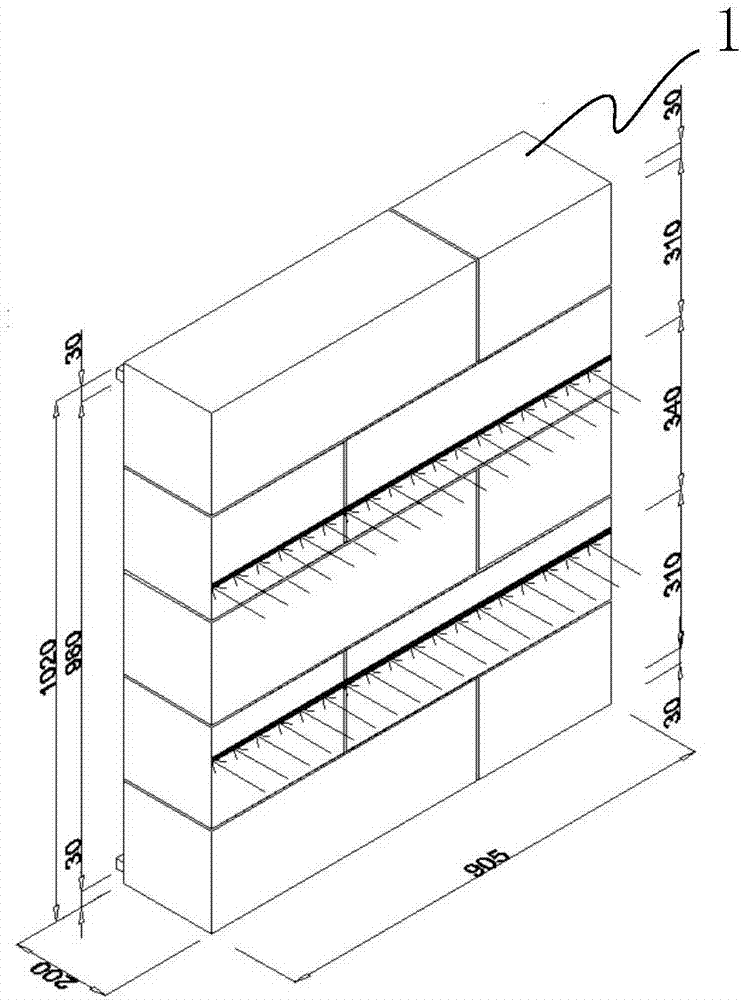

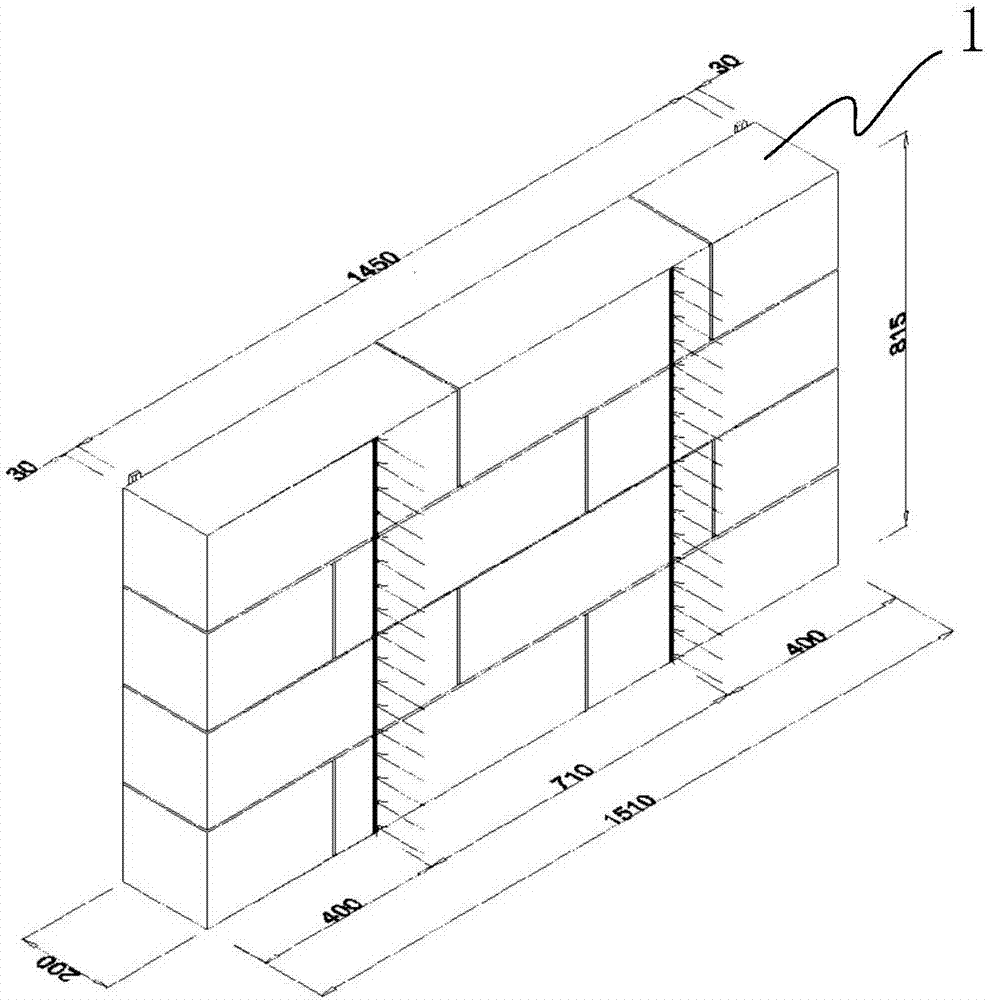

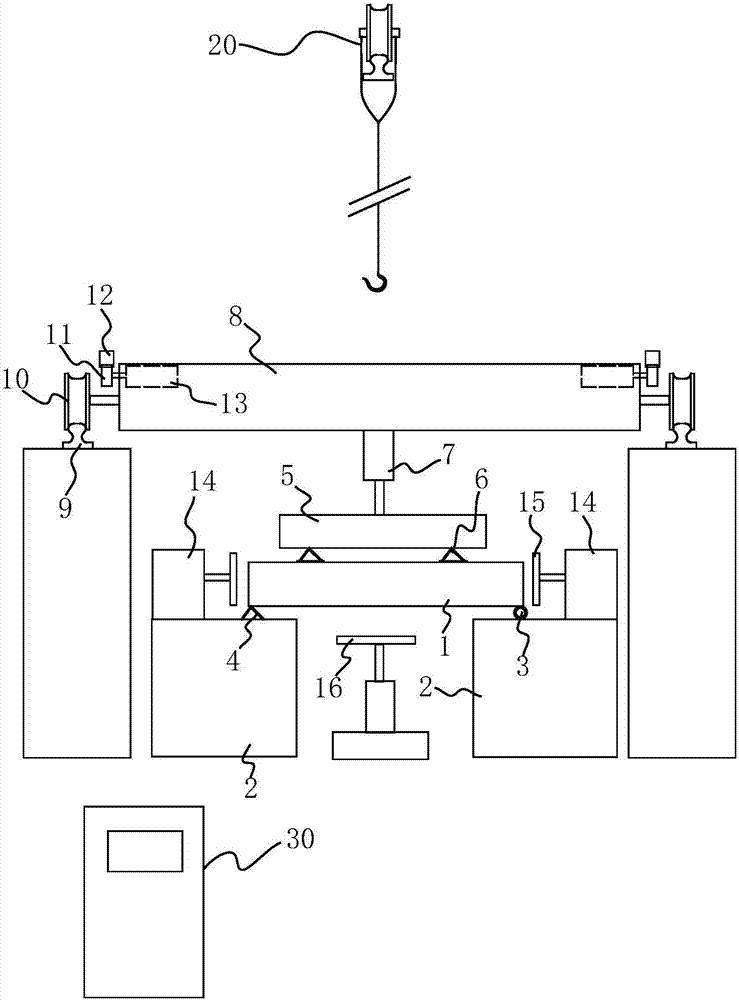

[0031] combine Figure 1~5 As shown, the present invention carries out the masonry 1 performance detection method of autoclaved aerated concrete block, and the steps include:

[0032] 1) Masonry 1. After the maintenance is completed, put the masonry 1 down and transfer it to the loading platform of the testing equipment; lay the masonry 1 flat, use 3 round steel pipe pads at one end, and 4 angle steel pads at the other end Pad, the corners of the angle steel 4 are in contact with the lower surface of the masonry 1;

[0033] 2), then use jack 7 to apply load to the surface of masonry 1 from top to bottom; loading speed: 0.03-0.3N / mm per minute 2 , the loading speed is controlled according to the failure of the specimen within 3min to 5min;

[0034] 3) Record the failure load value and failure characteristics, calculate and process the test data to obtain the test results.

[0035] In terms of steps, the steps 1) are as follows: Figure 4 , 5 As shown, the masonry 1 is plac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com