Worn steel rail polishing target profile rapid design method

A design method and rail technology, applied in computer-aided design, design optimization/simulation, calculation, etc., can solve problems affecting rail grinding construction efficiency, long calculation cycle, and large amount of calculation, achieve good engineering application value, improve design Efficiency, the effect of improving efficiency and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the purpose, technical solution and advantages of the present invention clearer and clearer, the specific content of the present invention will be further described below in conjunction with the accompanying drawings, but the specific embodiments of the present invention are not limited thereto.

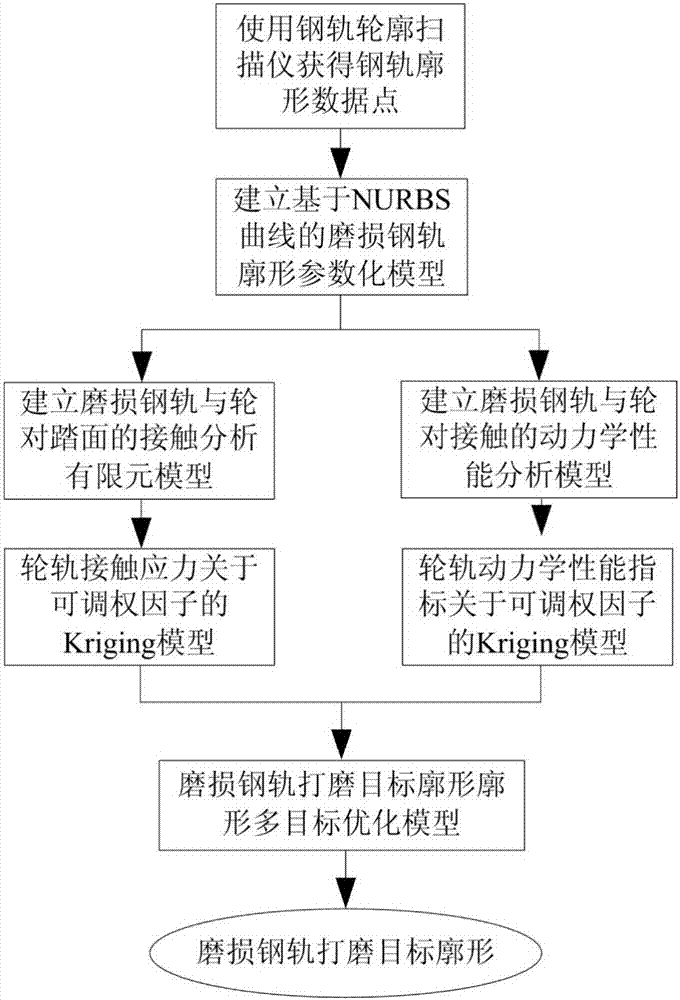

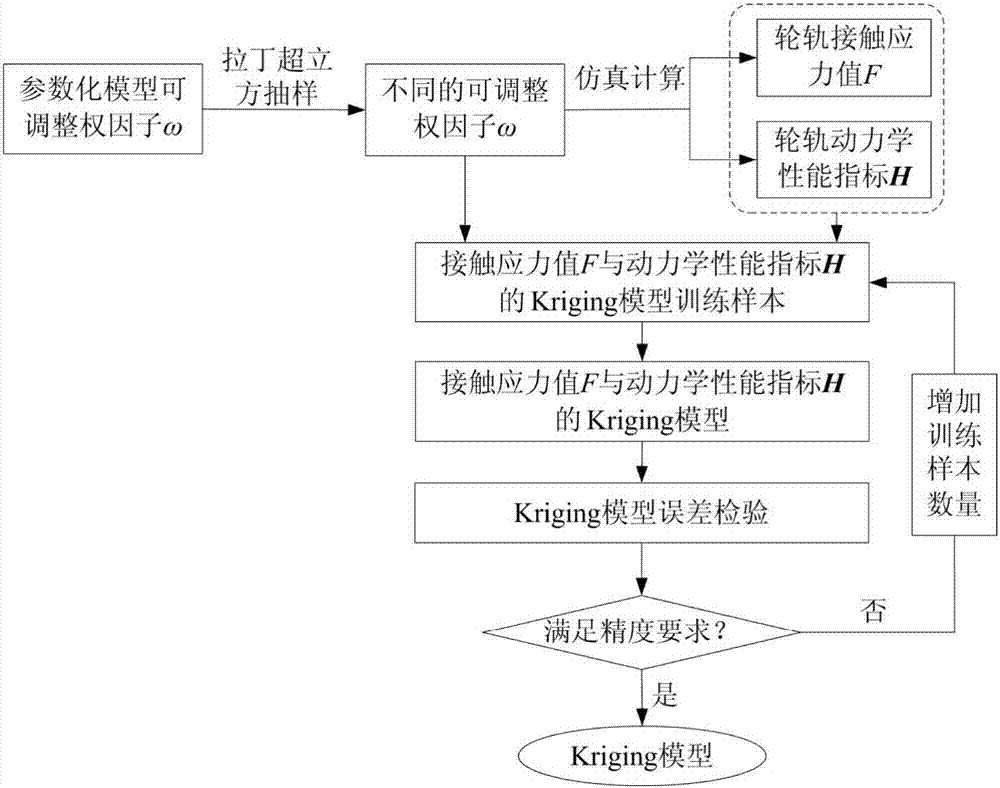

[0039] Such as figure 1 As shown, a rapid design method for the grinding target profile of worn rails includes the following steps:

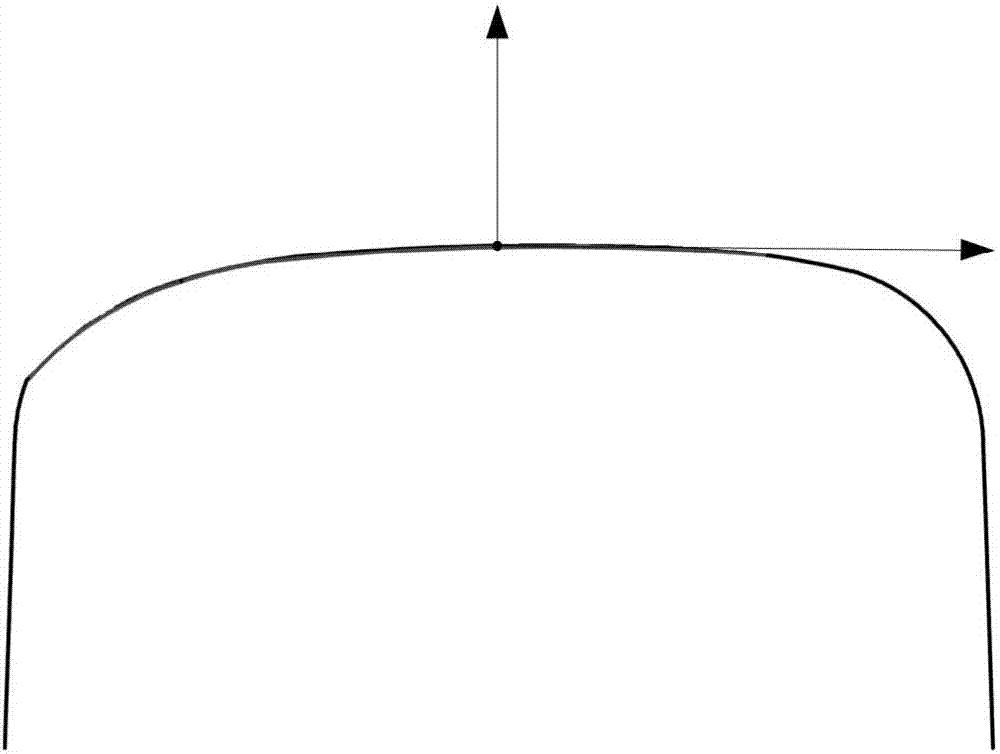

[0040] 1) build as figure 2 As shown in the global coordinate system of the rail profile, the rail profile scanner is used to obtain the data point coordinates of the profile of the worn rail section, which are used as the type value points of the NURBS curve to construct the polished cross-sectional profile of the worn rail based on the cubic NURBS curve Shape curve parametric model;

[0041] Described step (1) specifically comprises the following steps:

[0042] (1.1) Take the center of the rail top as the origin, take the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com