FDM type low-melting-point alloy 3D printer spraying head system and application thereof

A 3D printer, low melting point technology, applied in the direction of process efficiency improvement, additive manufacturing, additive processing, etc., can solve the problems of affecting printing accuracy, bulky structure, large nozzle volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below through the accompanying drawings.

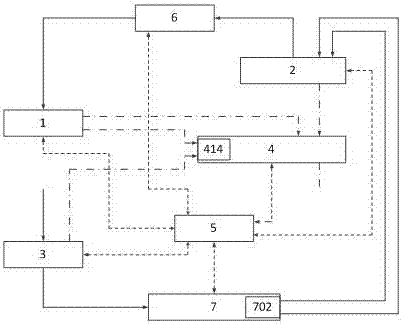

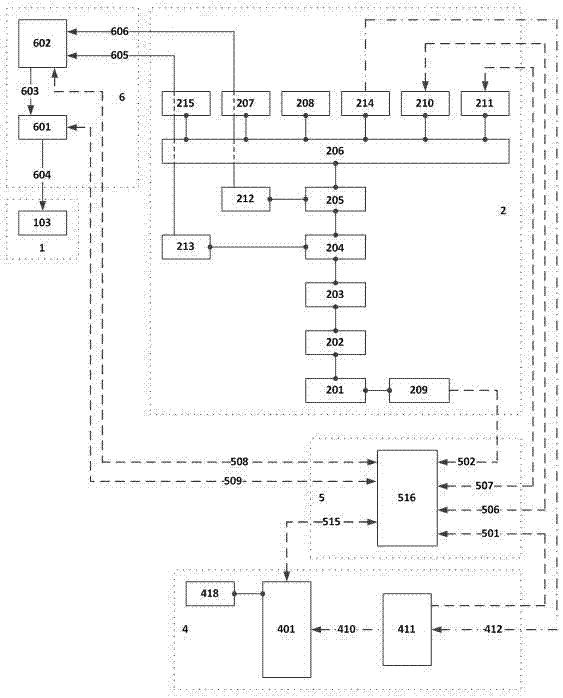

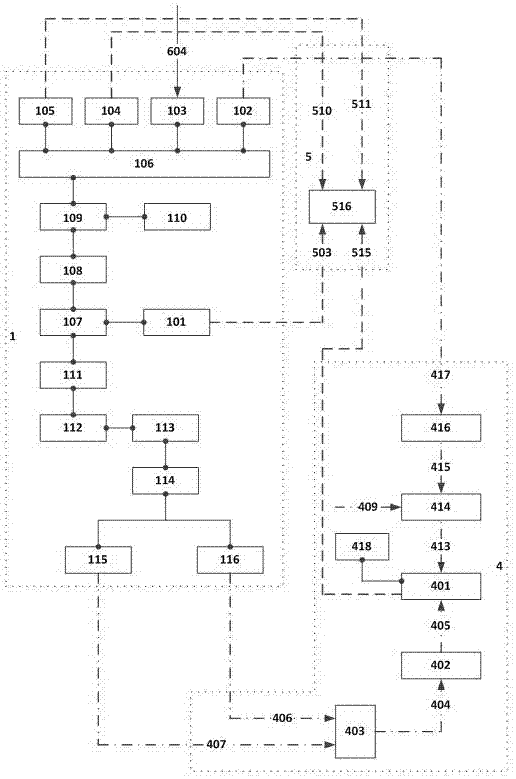

[0051] Such as Figure 1 to Figure 4 As shown, an FDM type low melting point alloy 3D printer nozzle system includes nozzle 1, molten low melting point alloy preparation device 2, recovery device 3, gas purification device 4, control device 5, feeding device 6 and extraction device 7; The device 6 conveys the printing material prepared by the molten low-melting alloy preparation device 2 to the nozzle 1; the extraction device 7 conveys the printing residue collected by the recovery device 3 from the nozzle 1 to the molten low-melting alloy preparation device 2; purification device 4 The harmful gases collected from the nozzle 1, the molten low melting point alloy preparation device 2 and the recovery device 3 are purified and discharged; the control device 5 passes through the first to fifth power supply wiring harnesses, the first to tenth power supply and signal wiring harnesses re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com