High precision grinding machine for bimetallic band saw blades

A bi-metal belt, high-precision technology, applied in metal sawing equipment, tool dressing of sawing machines, metal processing equipment, etc., can solve problems such as low grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

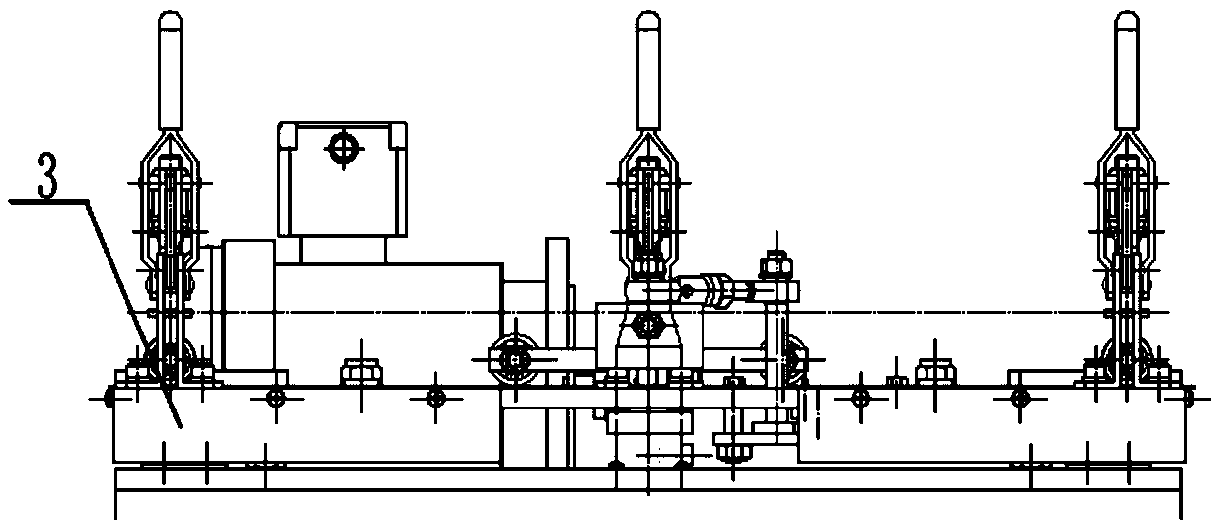

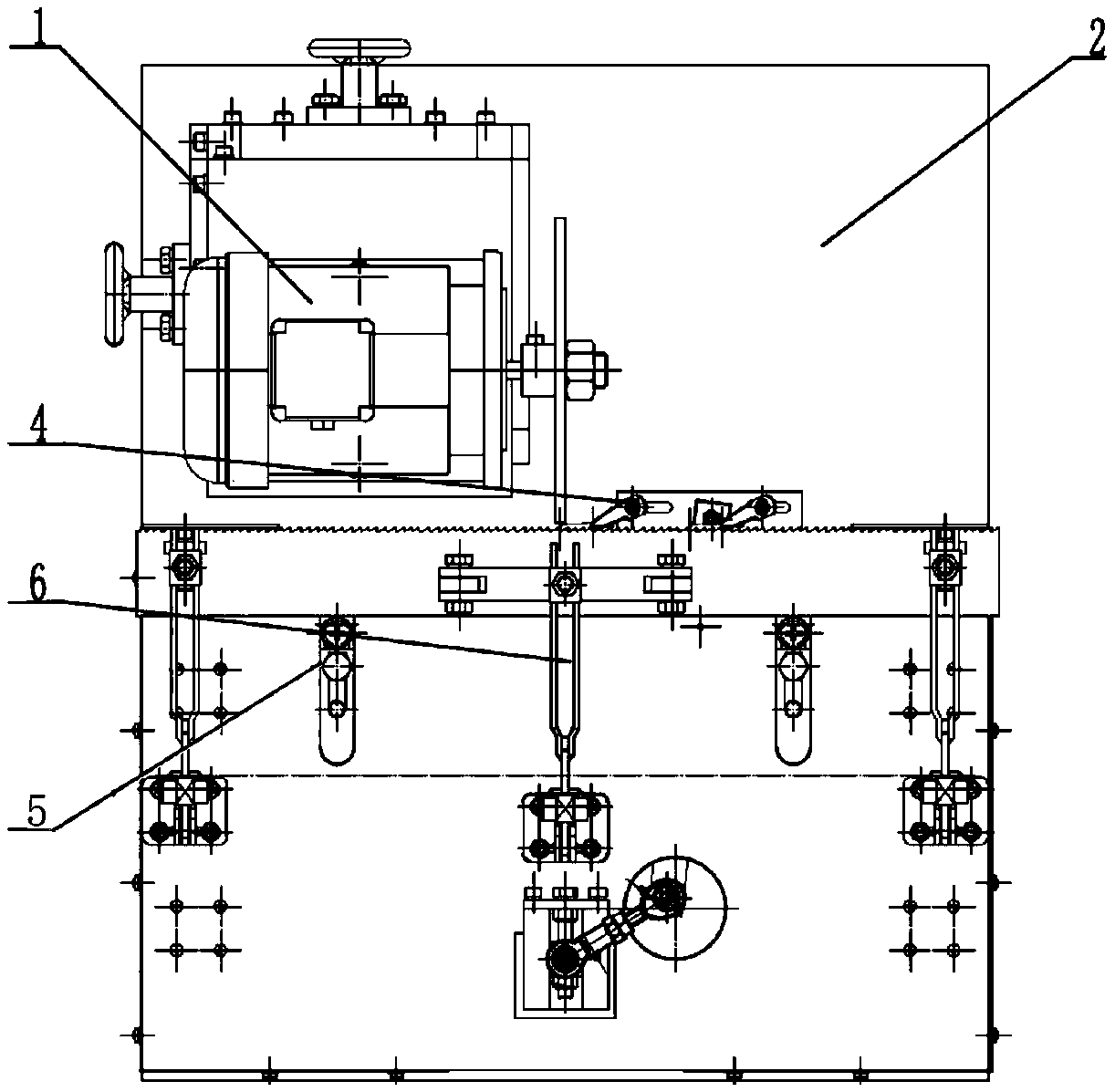

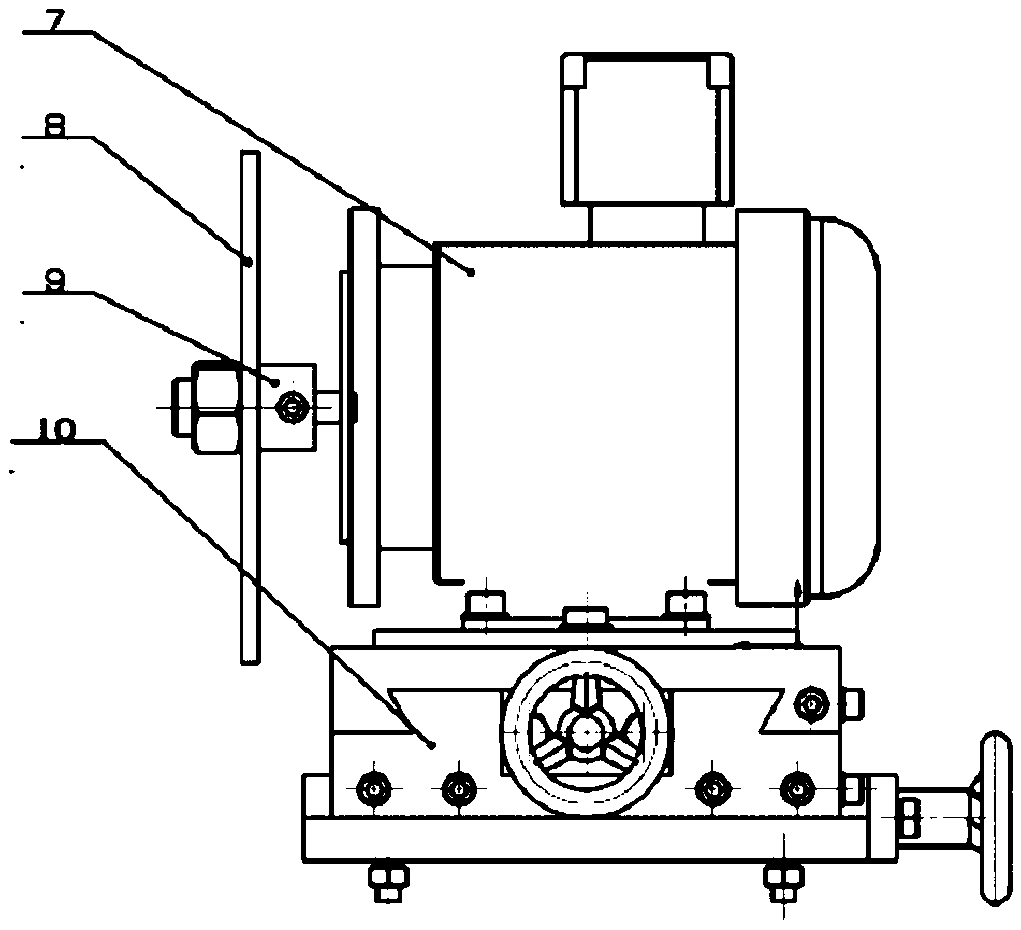

[0032] The invention provides a high-precision grinding machine tool for bimetallic band saw blades. The machine tool includes a grinding head mechanism 1, a workbench 2, a tooth-dividing grinding mechanism 3, a gear shifting mechanism 4, a positioning mechanism 5 and a clamping mechanism 6; The head mechanism 1 and the workbench 2 are respectively connected and installed on the electric control cabinet and the base. The tooth-dividing grinding mechanism 3 and the shifting gear mechanism 4 are both connected to the workbench 2 and installed inside the main frame. The positioning mechanism 5 and the clamping mechanism 6 All are connected and installed on the teeth-dividing grinding mechanism 3; the emery wheel 8 of the grinding head mechanism 1, the gear shifting mechanism 4, the positioning mechanism 5 and the clamping mechanism 6 are all corresponding to the stations where the saw blade is set.

[0033] The grinding head mechanism 1 includes a three-phase asynchronous motor 7,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com