Optical network electric wall polishing machine

A technology of wall grinding machine and optical mesh, which is applied to the parts of grinding machine tools, machine tools suitable for grinding workpiece planes, grinding machines, etc., can solve the problems of unreliability, low detection accuracy, low efficiency, etc. Decoration efficiency and quality, the effect of simple detection methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the implementation modes are not intended to limit the present invention.

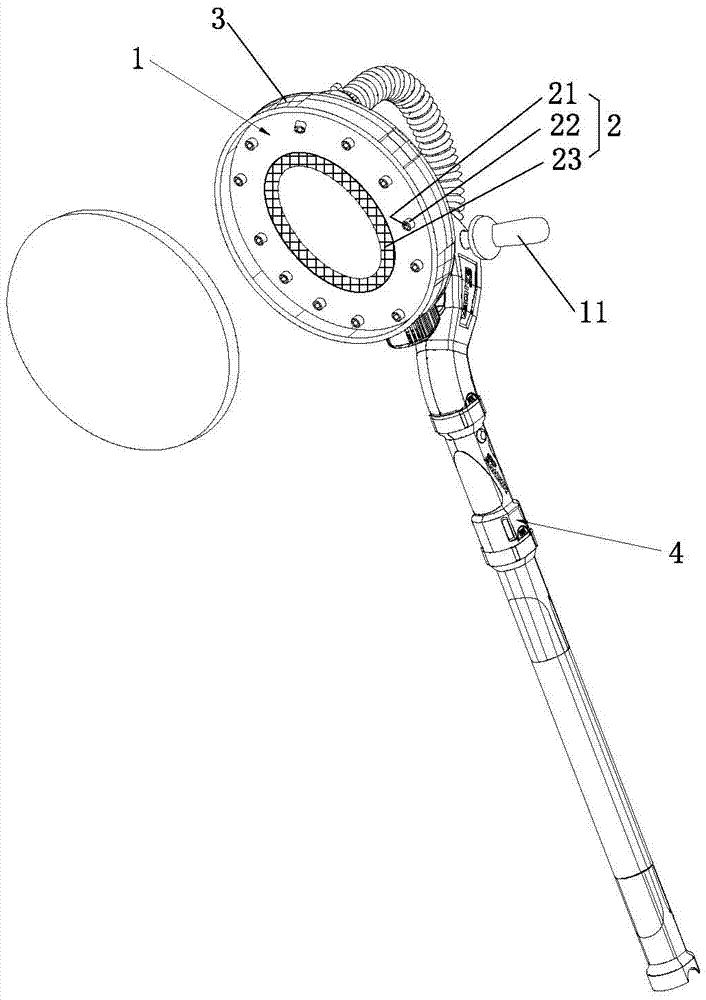

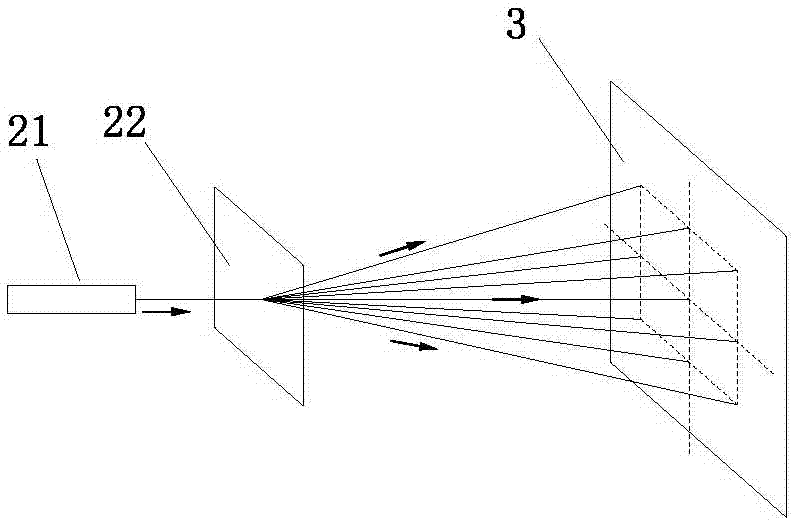

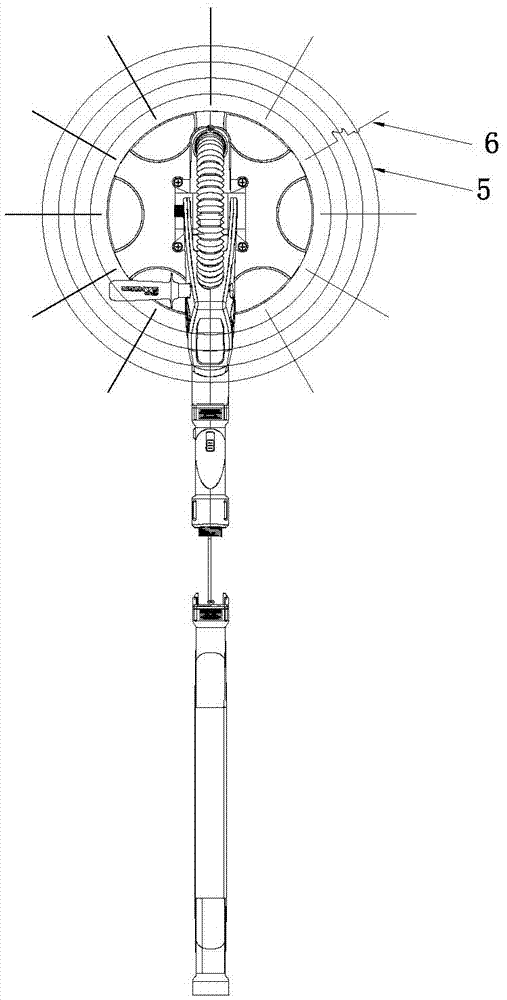

[0025] Please refer to Figure 1 to Figure 3 , an optical net electric wall grinder, comprising a grinding disc 1, said grinding disc 1 is provided with an optical net component 2 and a light-transmitting member 3, said optical net component 2 comprises a first light source 21 and a first light source for installation 21 is a light source cover 22, the light source cover 22 is arranged inside the grinding table 1, the light-transmitting member 3 is arranged on the grinding table 1, and the light source cover 22 is in a grid shape.

[0026] Specifically, in this embodiment, there are twelve optical network components 2, which are evenly distributed on the inner periphery of the grind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com