Forming device and method suitable for ultra-high pressure strengthening of square wood

A shaping device and ultra-high pressure technology, applied in wood compression, wood treatment, wood processing equipment, etc., can solve the problems of unfavorable wood later utilization and processing, achieve uninterrupted reliability, meet the continuity of pressure transmission, and strengthen reliable quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

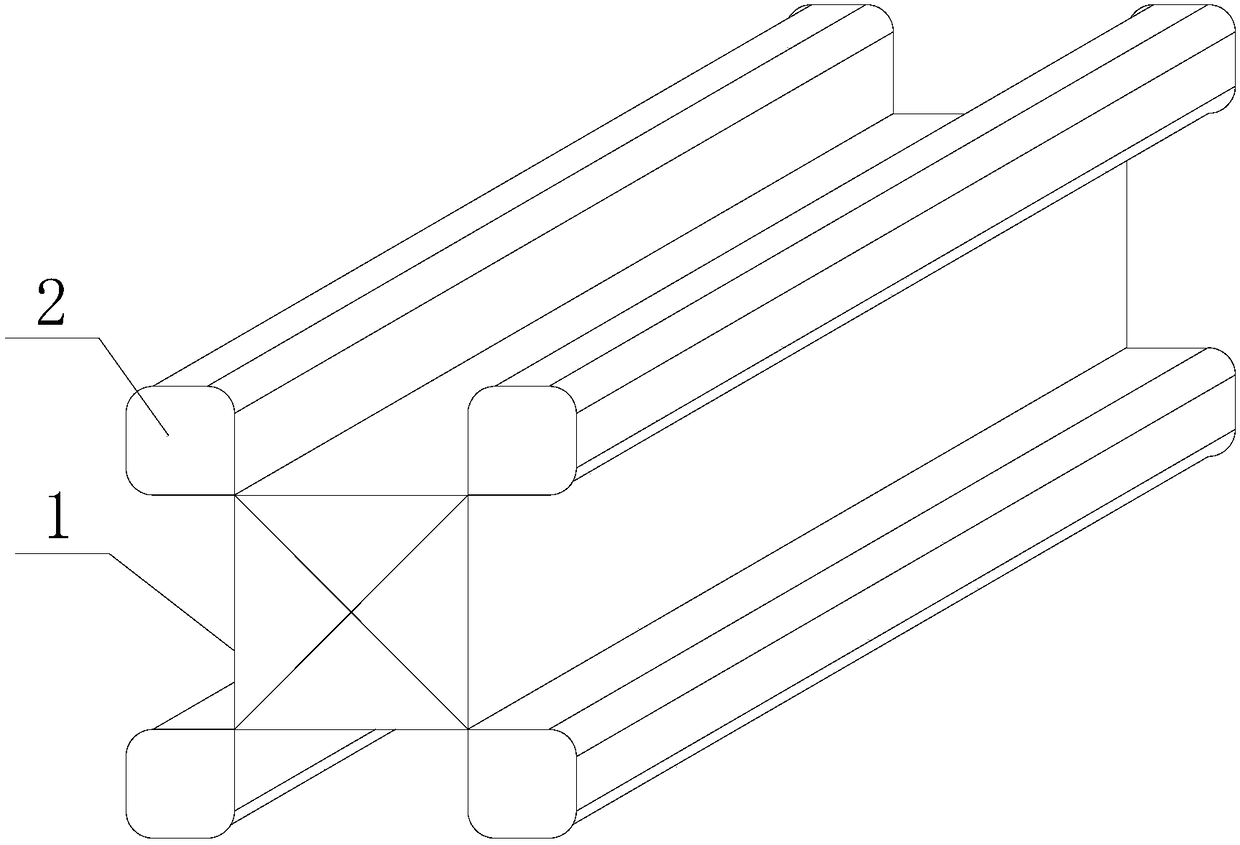

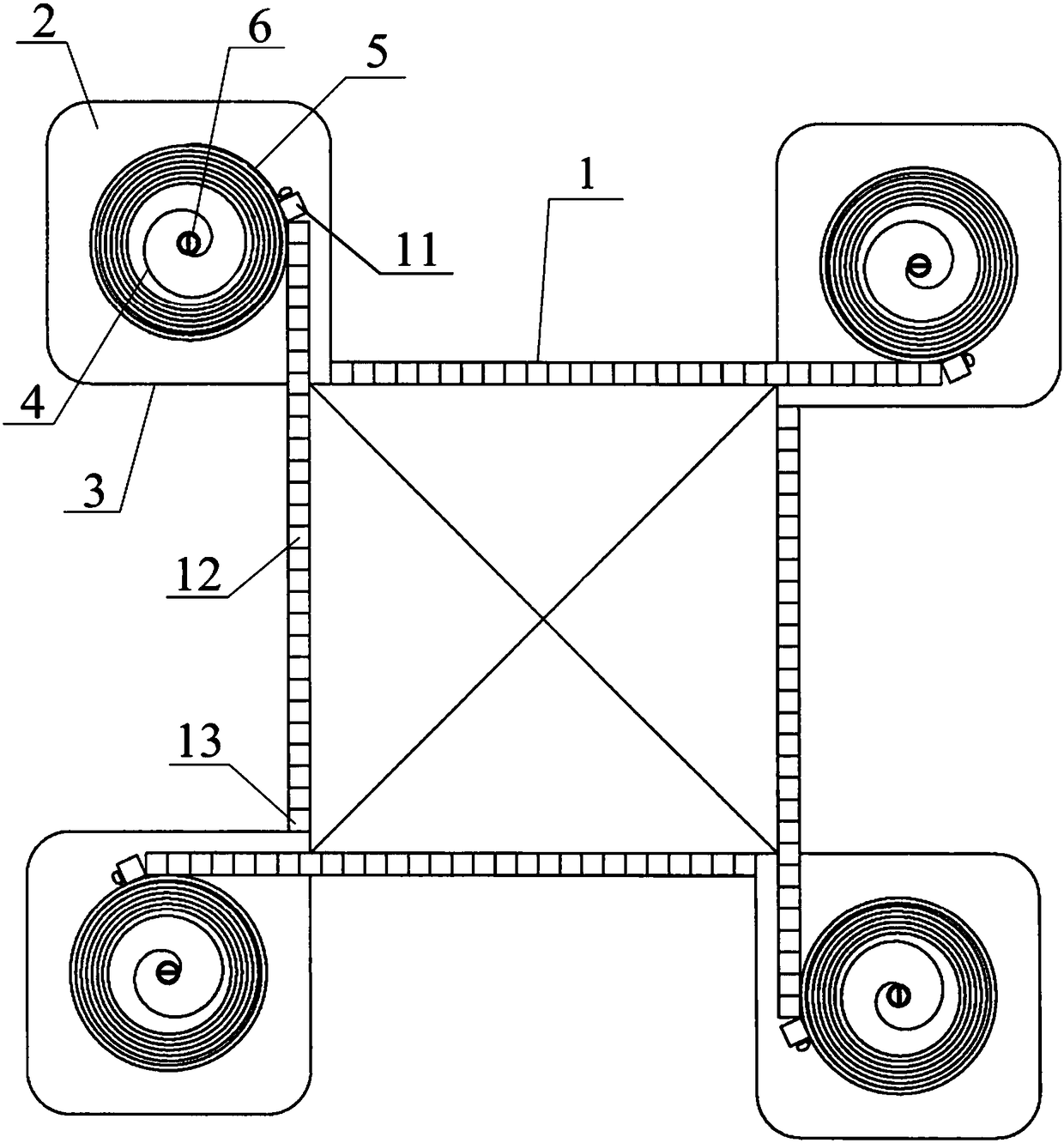

[0042] Embodiment 1, a kind of setting device that is suitable for square timber ultra-high pressure strengthening, such as Figure 1-7 As shown, it consists of four fixed parts; each fixed part includes a chain plane 1 and a plane vortex coil spring assembly 2; the four plane vortex coil spring assemblies 2 are arranged in a rectangle, that is, they are located at the four corners of the rectangle superior.

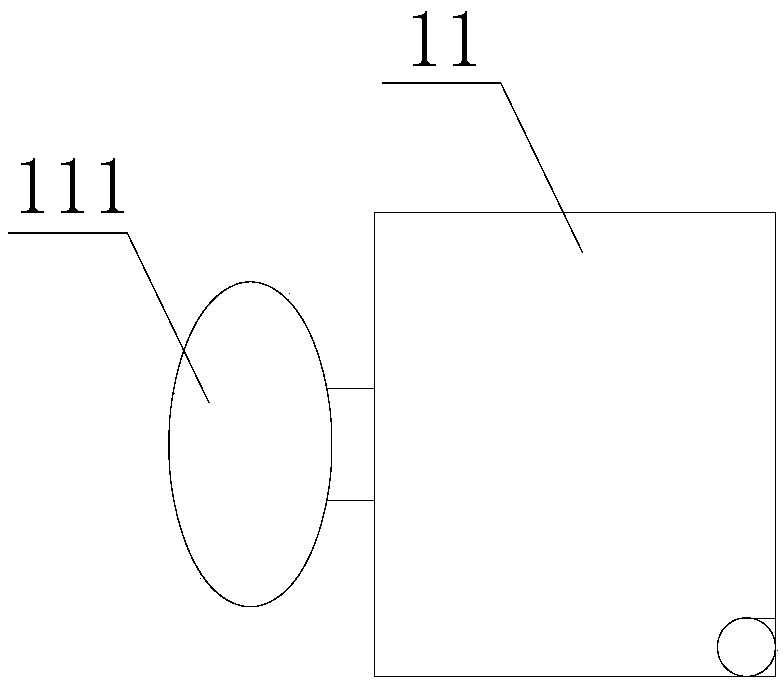

[0043] The chain plane 1 is composed of an initial connecting plate 11 fixedly connected in sequence, at least two intermediate connecting plates 12 and an end connecting plate 13; the number of intermediate connecting plates 12 can be specially adjusted according to actual needs.

[0044] One side of the starting connecting plate 11 is provided with pin holes, the opposite two sides of the intermediate connecting plate 12 are provided with pin holes, and one side of the end connecting plate 13 is provided with pin holes. The pin holes of the initial connecting plate 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com