Metal removing device and achieving method thereof

A metal removal device and metal technology, which is applied to the metal removal device that removes impurities efficiently, in the field of intelligence and high precision, can solve the problems of large production flow fluctuations, large amount of materials, metal inclusions, etc., and achieve simple and stable structure, Guaranteed detection accuracy and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

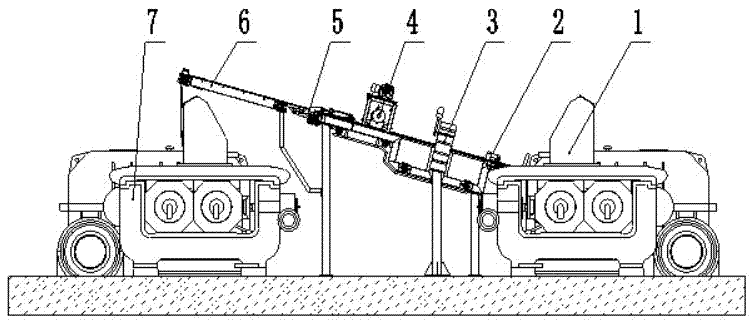

[0021] Such as figure 1 As shown, the present invention is a kind of metal rejecting device, and it comprises back and front track open mill 1, back conveying section 2, metal detection section 3, rotary cutter mechanism 4, impurity rejecting mechanism 5, front conveying 6 and back track opening Refining machine7.

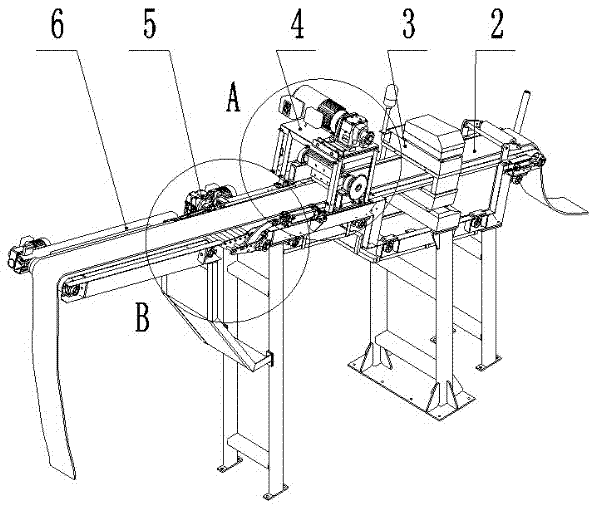

[0022] refer to figure 2 , showing the structural schematic diagram of the front conveying section 6 and the rear conveying section 2 of the present invention, the metal detection section 3, the rotary cutter mechanism 4, and the impurity removing mechanism 5 are sequentially installed on the rear conveying section 2 obliquely in a line, and the front conveying section 6 is placed at the forefront of the metal removal device.

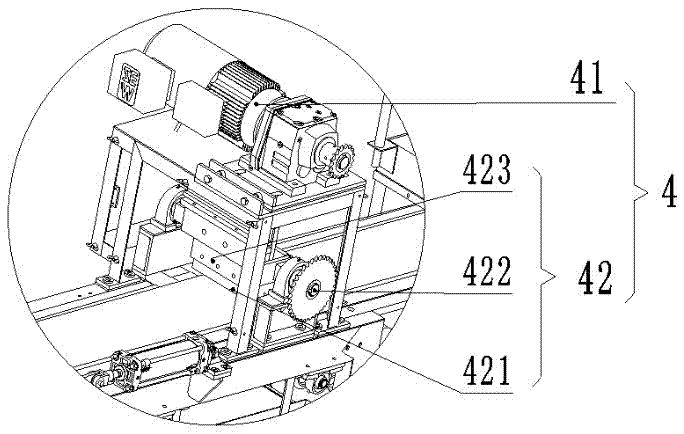

[0023] refer to image 3 , shows a schematic structural view of the rotary cutter mechanism 4 of the present invention, the rotary cutter mechanism 4 includes a motor 41 and a hot knife cutting device 42; the motor 41 is fixed above the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com