Containing frame for hollow glass transportation

A pallet and glass technology, applied in the direction of transportation and packaging, packaging, packaging of vulnerable items, etc., can solve the problems of unusable hollow glass, hidden safety hazards, poor stability, etc., to improve space utilization and improve the limit function , to avoid the effect of pressure damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

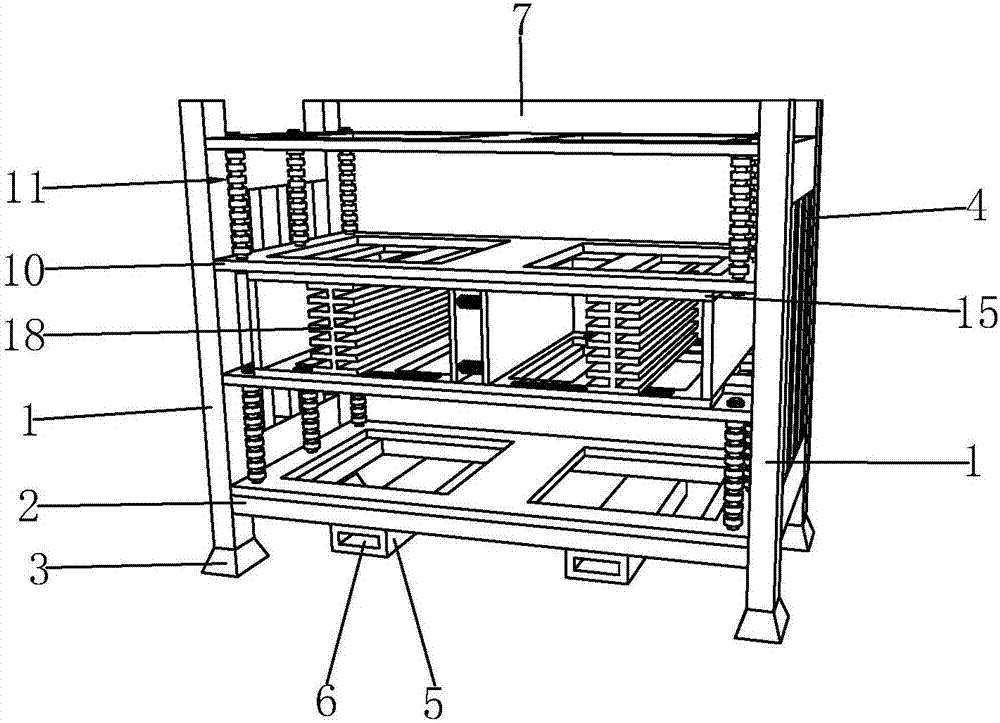

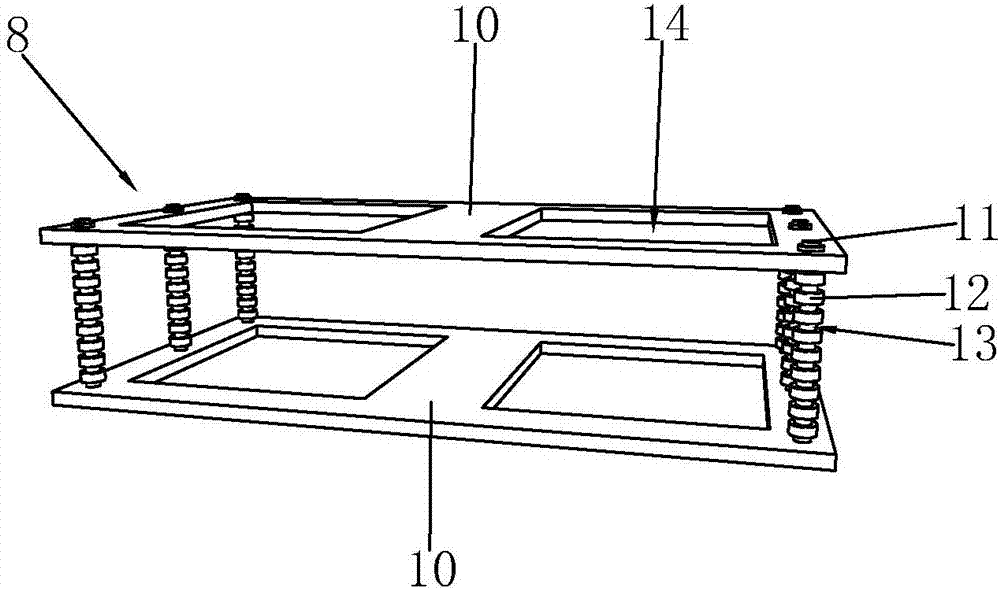

[0025] Such as Figure 1 to Figure 5 Shown here is a pallet for the transportation of hollow glass of the present invention, which includes a frame body 1, a bottom plate 2 and a support leg 3. The frame body 1 is vertically distributed with reinforcing ribs 4, and the reinforcing ribs 4 are provided with a reinforcing frame body 1. Its structural strength improves its stability, the support is stable, and it is not easy to fall apart. The feet 3 are arranged at the bottom of the frame body 1 to increase the gripping area and improve the support stability. The bottom plate 2 is arranged between the frames 1, and the bottom of the bottom plate 2 is symmetrically distributed with a fixed frame 5, and the fixed frame 5 is provided with a socket 6 which passes through the fixed frame 5 transversely. Insert the forklift of the forklift into the socket 6. The pallet is moved steadily as a whole for easy transportation.

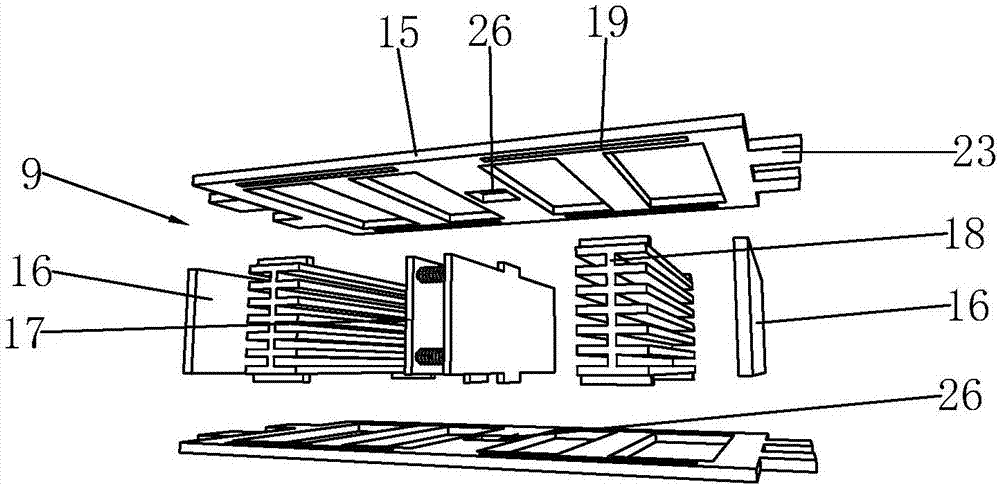

[0026] A back baffle 7, a storage rack 8 and a storage basket 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com