A battery cathode catalyst, preparation method and application in metal-air batteries

A cathode catalyst and battery technology, applied in the field of battery cathodes and metal-air batteries, can solve the problems of reducing battery energy efficiency, easy agglomeration, and reducing silver utilization efficiency, achieving good redox characteristics, improving energy efficiency, and improving oxygen efficiency. The effect of migration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention also provides a method for preparing a battery cathode catalyst, comprising the following steps:

[0031] A) mixing and stirring silver powder, cerium salt, dispersant, complexing agent and water to obtain a sol;

[0032] B) The sol is subjected to hydrothermal reaction and calcined in sequence to obtain a battery cathode catalyst.

[0033] In the invention, silver powder, cerium salt, dispersant and complexing agent are dispersed in water and stirred to obtain sol. In the present invention, there is no special limitation on the mixing and stirring method, as long as the raw materials can be mixed and stirred to obtain a sol, and the stirring is preferably magnetic stirring. In the present invention, the mixing and stirring temperature is preferably 60-100°C, preferably 70-90°C. The mass ratio of the nano silver powder to the cerium salt is 1: (0.1~100), the mass ratio of the dispersant to the nano silver powder is 1: (0.1~10), and the mass ratio...

Embodiment 1

[0049] Take by weighing 1g nano silver powder (purchased from Aladdin company, size 60~120nm), 7g cerium nitrate according to nano silver powder and cerium salt ratio 1:7, take by weighing 3g polyvinylpyrrolidone according to dispersant and nano silver powder mass ratio 3:1, Weigh 21g of citric acid according to the mass ratio of complexing agent to cerium salt of 3:1, add it to a beaker, add 200mL deionized water, stir at 60-100°C until it is in the form of a sol, transfer the sol to a reaction kettle at 200°C The reaction was carried out for 3 hours, and then calcined at 700°C for 5 hours to obtain the cathode catalyst for the battery.

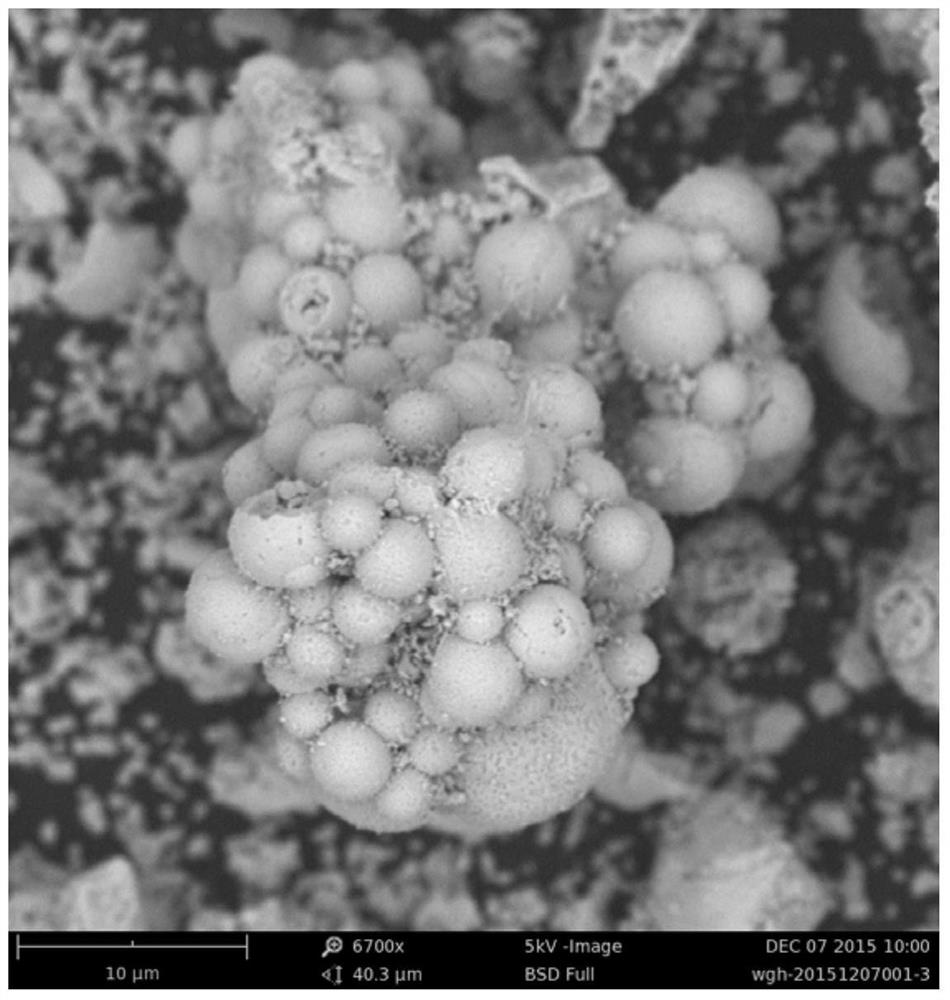

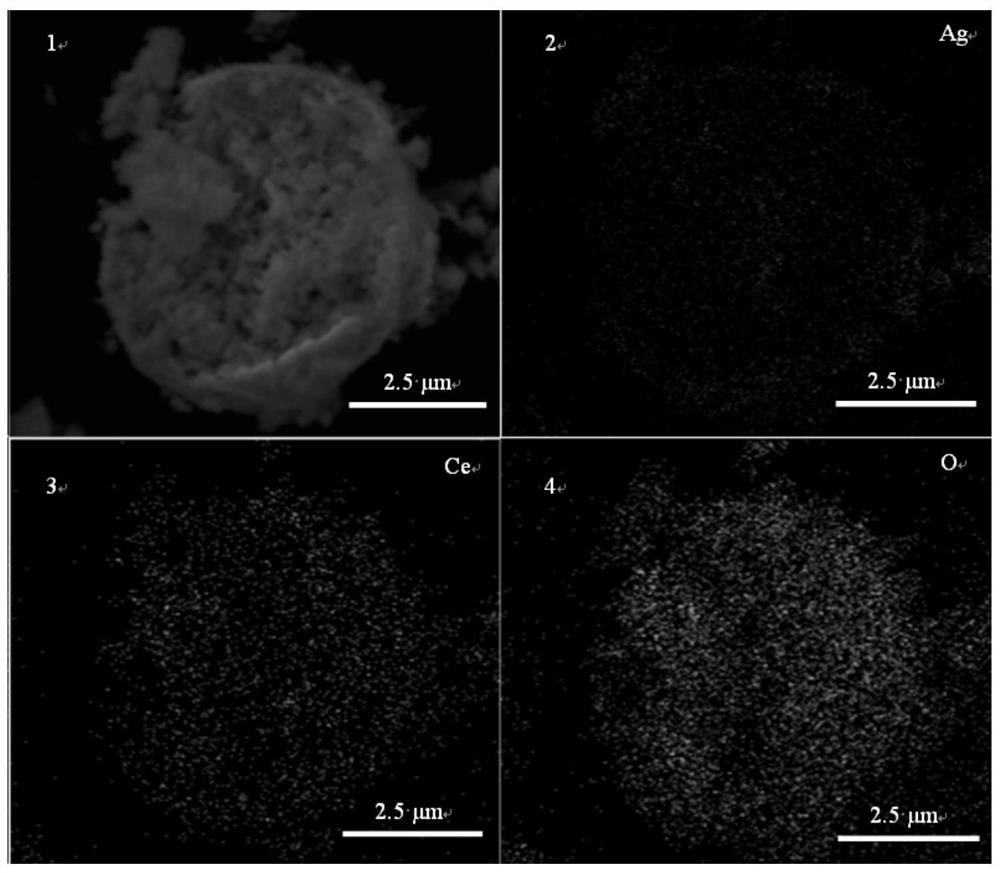

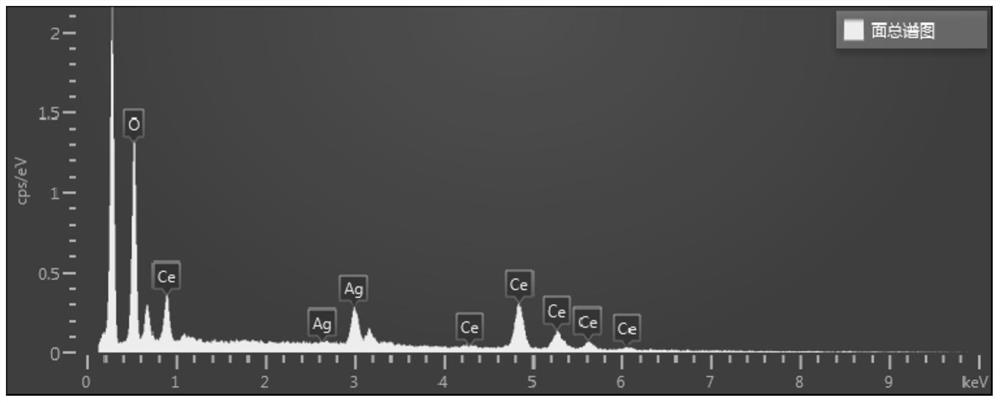

[0050] Scanning electron microscope observation and energy spectrum analysis are carried out to the battery negative electrode catalyst that above-mentioned obtains, and the result is as follows figure 1 , figure 2 with image 3 as shown, figure 1 It is an SEM image of the battery cathode catalyst provided in Example 1 of the present inv...

Embodiment 2

[0061] Take by weighing 5g nano-silver powder (purchased from Aladdin company, size 60~120nm), 1g cerium nitrate according to the ratio of nano-silver powder and cerium salt of 5:1, take by weighing 1.67g polyvinylpyrrolidone according to the mass ratio of dispersant and nano-silver powder 1:3 According to the mass ratio of complexing agent and cerium salt 1:2, weigh 0.5g of citric acid, add it to a beaker, add 200mL deionized water, stir at 80°C until it is in the form of a sol, transfer the sol to a reaction kettle at 400°C The reaction was carried out for 1 h, and then calcined at 1000 ° C for 1 h to obtain the cathode catalyst for the battery.

[0062] Carry out scanning electron microscope observation to the above-mentioned battery cathode catalyst that obtains, the result is as follows Figure 5 as shown, Figure 5 It is the SEM image of the catalyst for battery cathode provided by Example 2 of the present invention.

[0063] The particle size of the cathode catalyst o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com