Combined machine for recycling and packaging residual film

A combined operation machine and residual film recovery technology, which is applied in the field of agricultural machinery, can solve the problems of being easily affected by strong winds, residual film binding, difficult loading and transportation, etc., and achieves simple and feasible operation, low manufacturing cost, difficult loading and transport effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention is further described below in conjunction with embodiment.

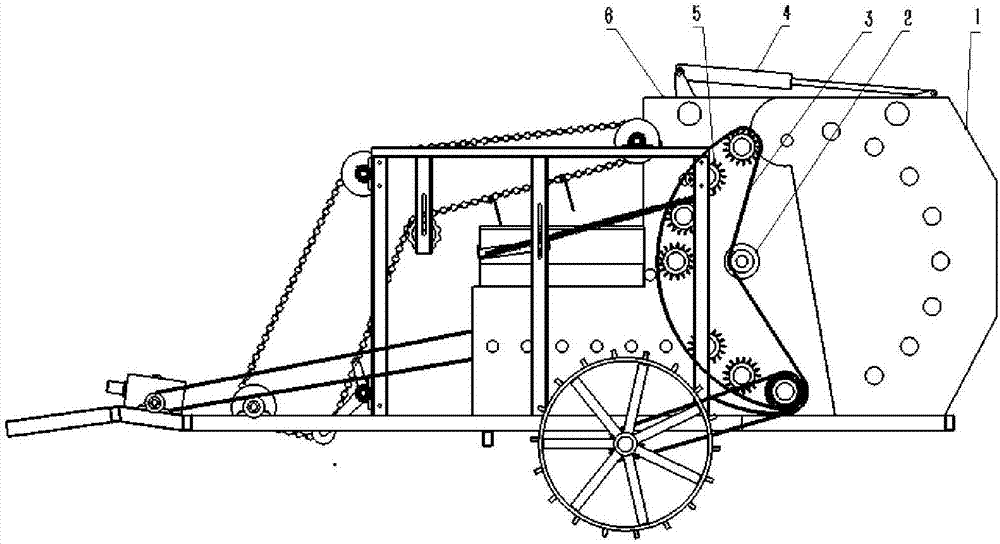

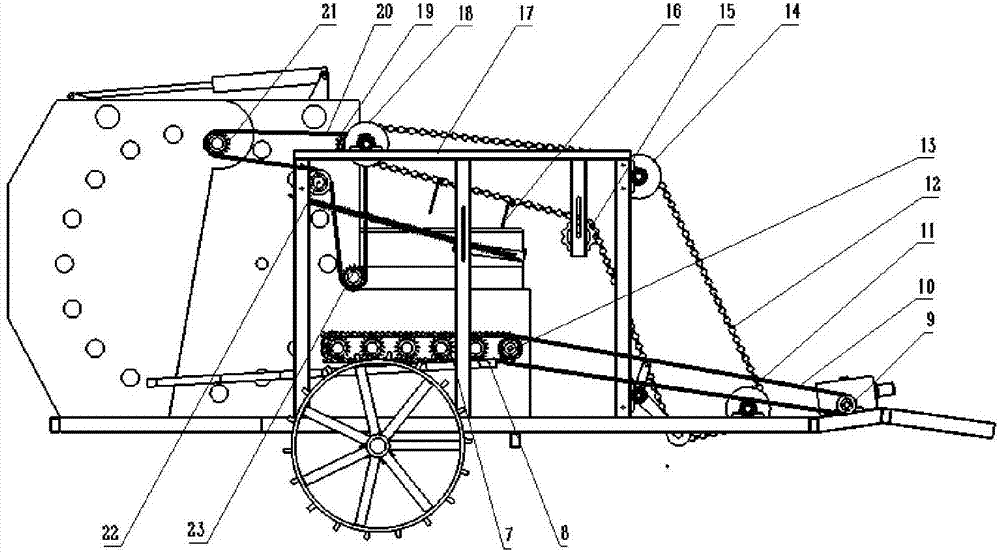

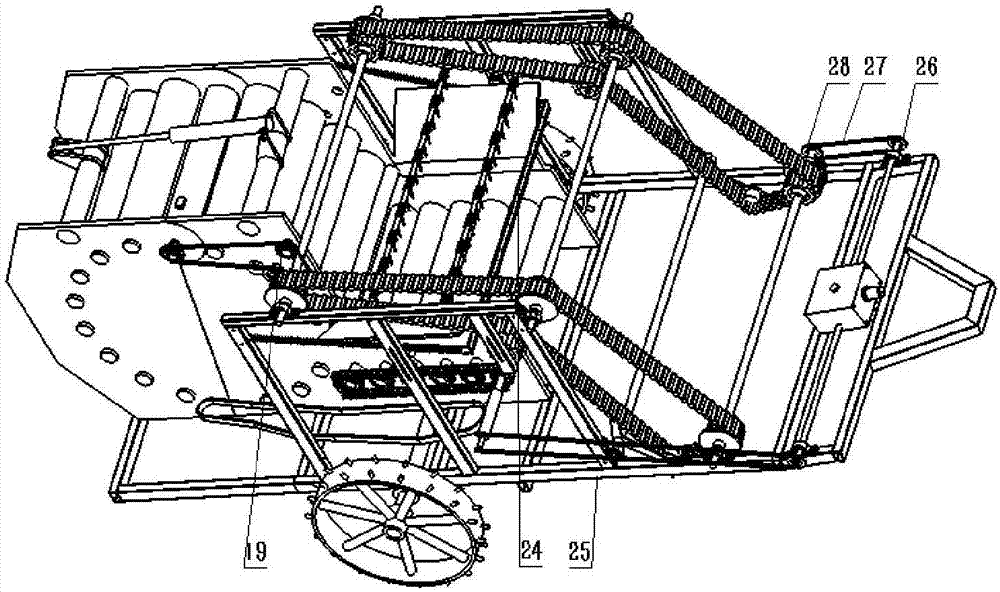

[0059] like Figure 1 ~ Figure 4 As shown, the combined operation machine for recycling and packaging residual film of the present invention includes a frame main body, a speed reducer 36, a film picking device, a scraping film plate 24 and a residual film packaging device.

[0060] The frame main body includes a bracket 17 , a vehicle frame 25 , wheels 29 and a suspension 37 . Described support 17 is positioned at the middle part of vehicle frame 25, is used for supporting film pick-up device and scraper plate 24, and wheel 29 is arranged on vehicle frame 25 by axle, and suspension 37 is arranged on the front end of vehicle frame 25, is used to link to each other with traction device .

[0061] The speed reducer 36 is fixedly connected to the front part of the vehicle frame 25, and is connected with the rear output shaft of the traction device through a universal joint. The power take...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com