A palladium/graphene catalyst for dehydrogenation of dodecahydroethylcarbazole and preparation method thereof

A technology of dodecahydroethylcarbazole and catalyst, applied in the field of palladium/graphene catalyst and its preparation, to achieve the effects of increased selectivity, low cost and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

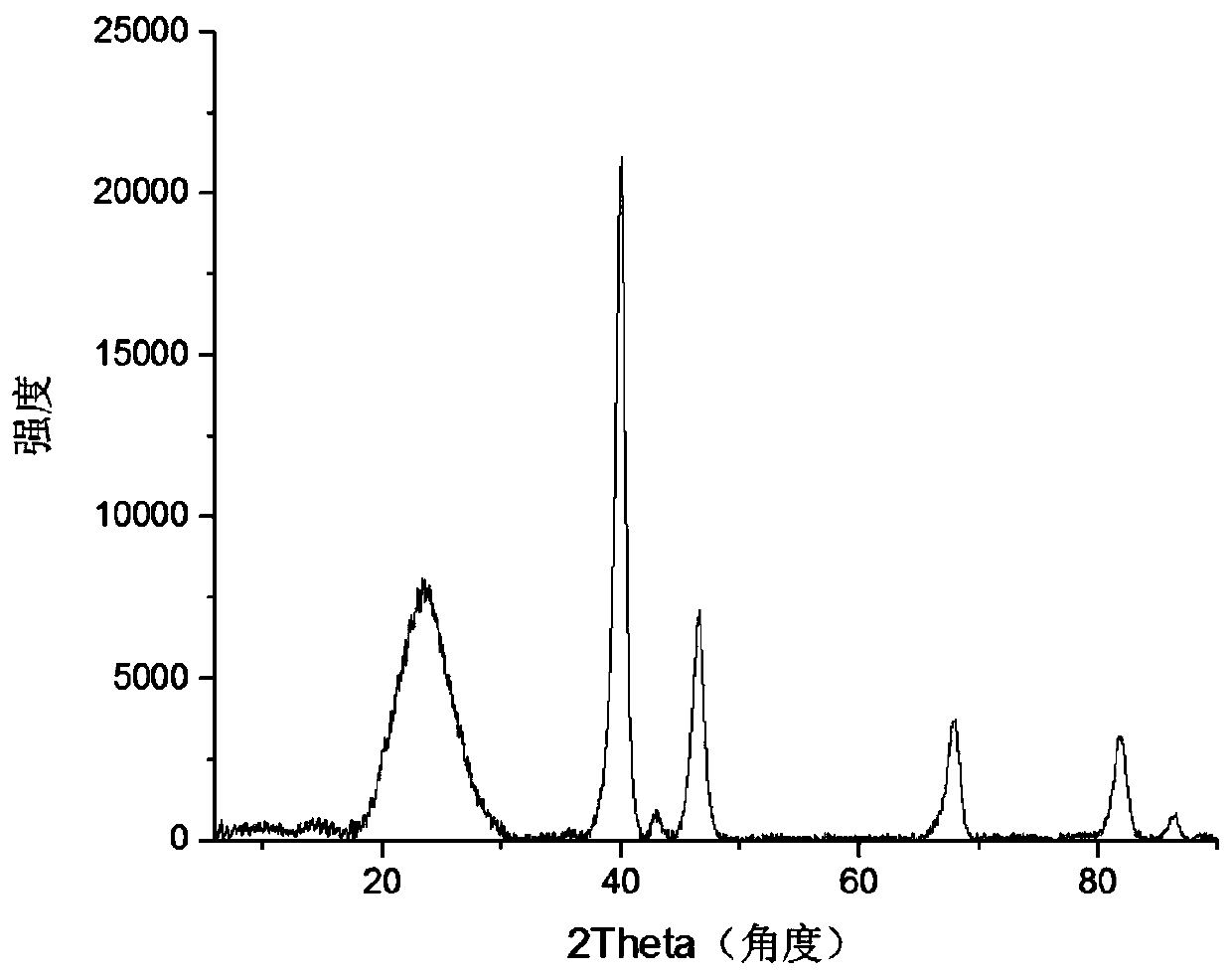

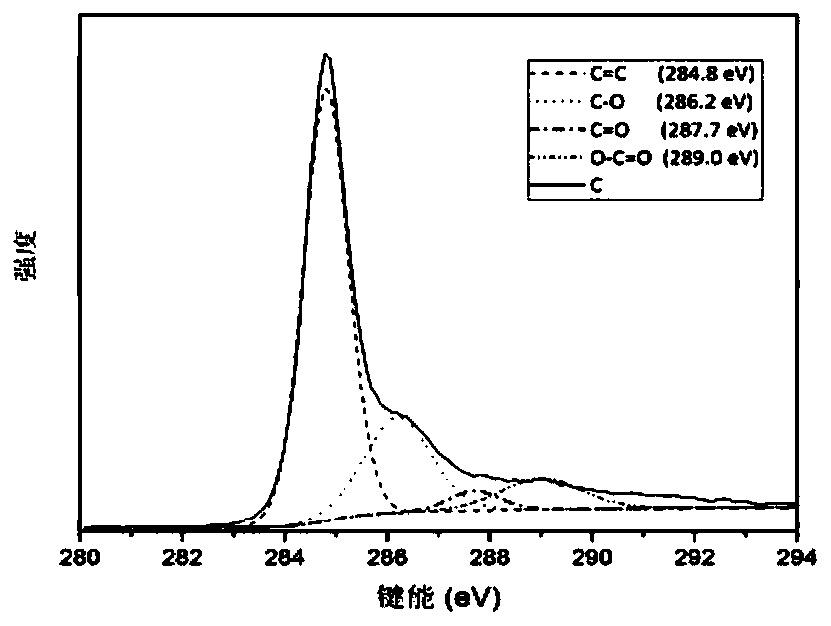

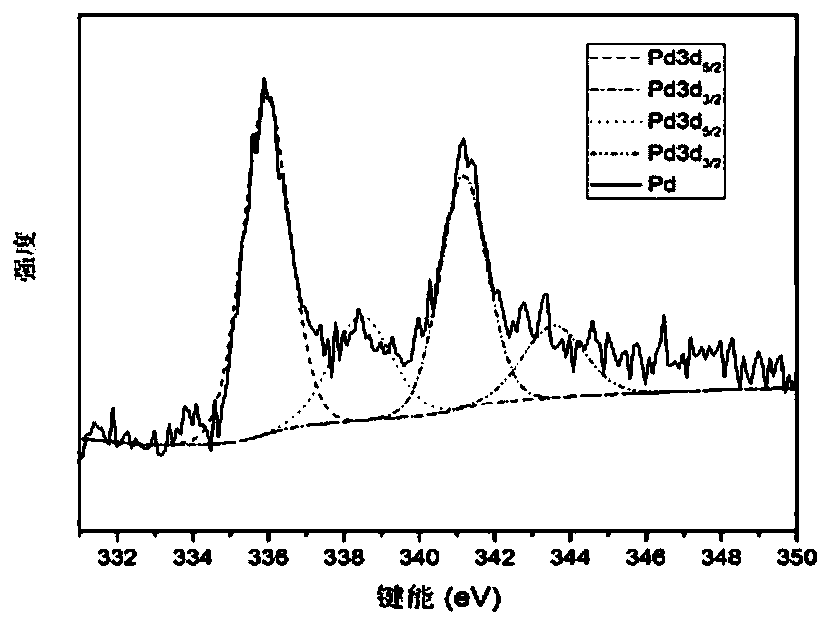

[0037] Graphite oxide was prepared by the Hummer method, the product was suction filtered, then washed with distilled water to pH = 6, and dried in a vacuum oven at 60°C for 24 hours; the dried product was added to a ball mill tank containing n-heptane solution, and the ball mill was used for auxiliary pre-stripping for 4 hours , the speed of the ball mill is 500 rpm; weigh 0.5g of graphite oxide powder obtained by ball milling and place it in a conical flask, add 50ml of distilled water and stir for 2h to mix evenly, place the conical flask in a 150w ultrasonic cleaner for 1h, and then use Ultrasonic pulverization with a 600w cell pulverizer for 1 hour to obtain a graphene oxide dispersion.

[0038] Add palladium chloride to the obtained graphene oxide dispersion, add according to the palladium mass fraction of 5wt%, and stir the solution for 12 hours, then add the above solution into a 500ml three-necked flask, add 200ml of ethylene glycol, and react at 120°C for 12h , The w...

Embodiment 2

[0046] Graphite oxide was prepared by the Brodie method, the product was suction-filtered, then washed with distilled water to pH = 5, and dried in a vacuum oven at 60°C for 24 hours; the dried product was added to a ball mill tank containing n-hexane solution, and the ball mill was used for auxiliary pre-stripping for 4 hours. The speed of the ball mill is 800 rpm; weigh 0.5g of the graphite oxide powder obtained by ball milling and place it in a conical flask, add 50ml of distilled water and stir for 2h to mix well, put the conical flask in a 200w ultrasonic cleaning machine for 1h, and then use an 800w The cell pulverizer was ultrasonically pulverized for 1 hour to obtain a graphene oxide dispersion.

[0047] Add palladium chloride to the obtained graphene oxide dispersion, add according to the palladium mass fraction of 3wt%, and stir the solution for 12 hours, then add the above solution into a 500ml three-necked flask, add 250ml of ethylene glycol, and react at 110°C for ...

Embodiment 3

[0049] Graphite oxide was prepared by the Standenmaier method, the product was suction filtered, then washed with distilled water to pH = 3, and dried in a vacuum oven at 60°C for 24 hours; the dried product was added to a ball mill tank containing n-heptane solution, and the ball mill was used for auxiliary pre-stripping for 4 hours , the speed of the ball mill is 1000 rpm; 0.5g of graphite oxide powder obtained by ball milling is weighed and placed in a conical flask, and 50ml of distilled water is added to stir for 2h to mix evenly. Ultrasonic pulverization with a 450w cell pulverizer for 1 hour to obtain a graphene oxide dispersion.

[0050] Add palladium chloride to the obtained graphene oxide dispersion, add according to the palladium mass fraction of 7wt%, stir the solution for 12 hours, add the above solution into a 500ml three-necked flask, add 200ml of ethylene glycol, and react at 110°C for 10h , The whole reaction was protected by argon gas. After the reaction, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com