Positioning pin locking mechanism

A locking mechanism and positioning pin technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve problems such as low work efficiency, complex structure of positioning pin locking mechanism, troublesome operation, etc., and achieve simple structure and easy operation Smooth, reliable, and easy-to-use results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with specific examples.

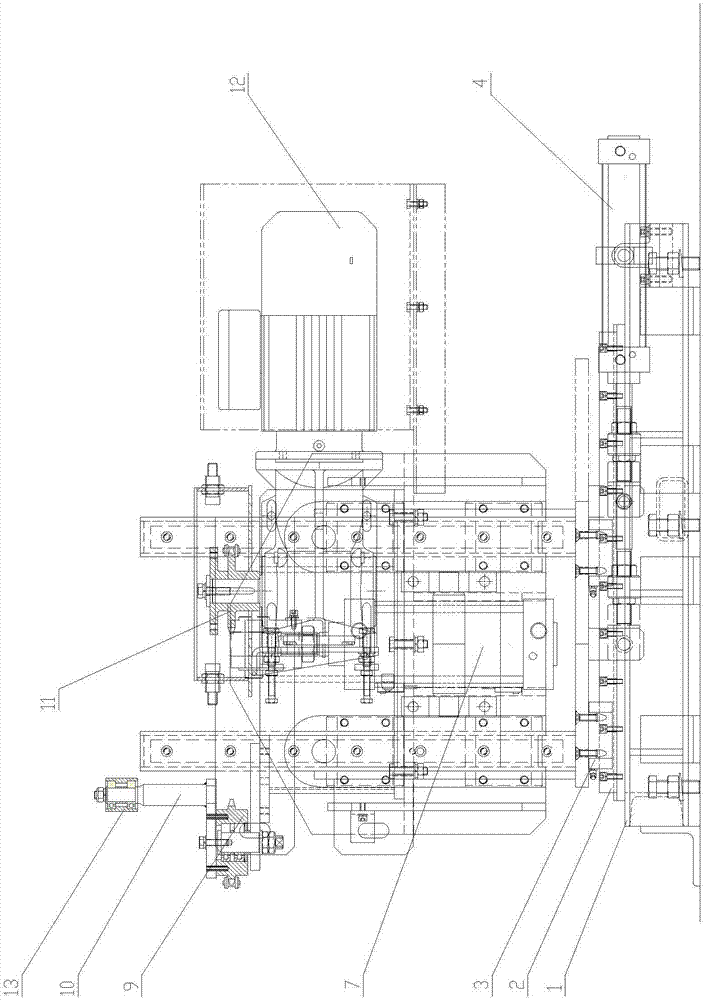

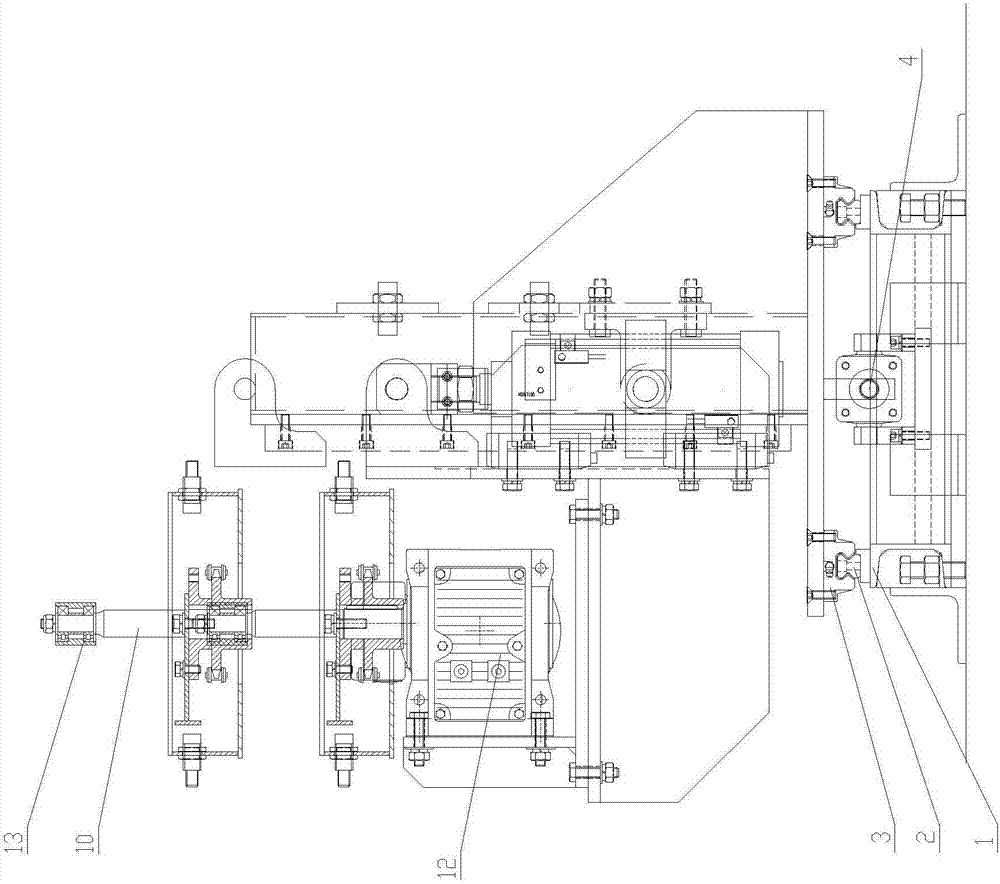

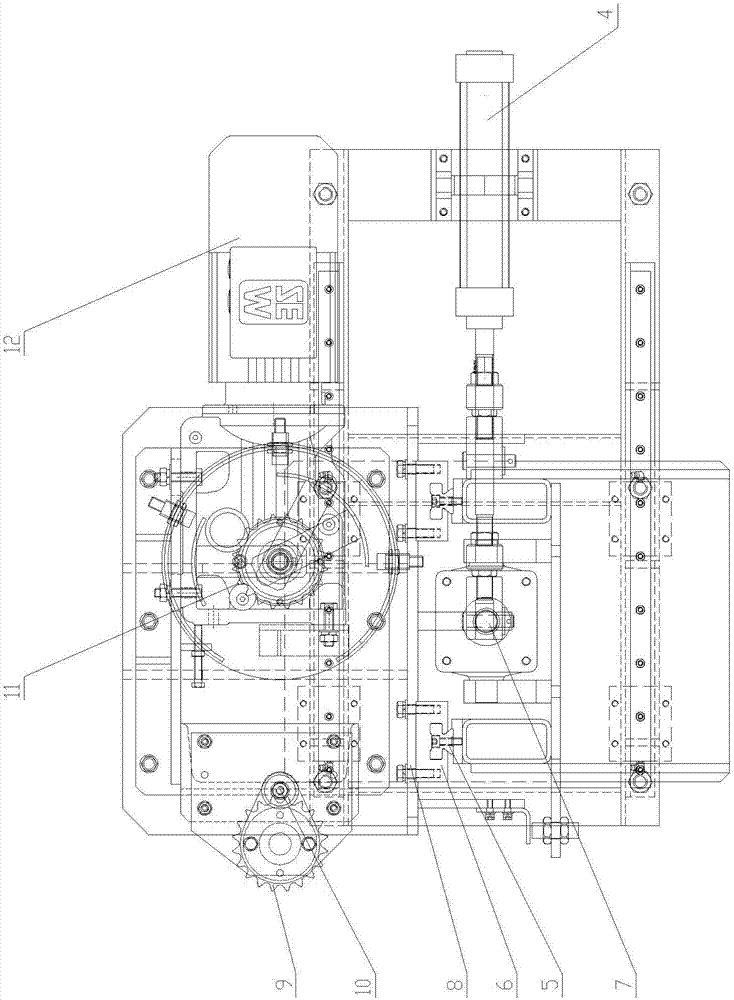

[0012] The positioning pin locking mechanism includes a frame 1, a horizontal linear slide rail 2, a horizontal slider 3, a horizontal drive cylinder 4, a vertical linear slide rail 5, a vertical slide block 6, a vertical drive cylinder 7, and a mounting frame 8 , passive sprocket 9, locking positioning pin 10, driving sprocket 11 and drive motor 12; horizontal linear slide rail 2 and horizontal drive cylinder 4 are fixed on frame 1, and horizontal linear slide rail 2 is slidably installed in horizontal linear slide rail 2. The slide block 3, the cylinder head of the horizontal drive cylinder 4 is connected with the horizontal slide block 3, the vertical linear slide rail 5 and the vertical drive cylinder 7 are fixed on the horizontal slide block 3, and the vertical linear slide rail 5 is slidably installed with Vertical slide block 6, vertical drive cylinder 7 is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com