Integrated liquid-solid separating device for sewage treatment

A sewage treatment and solid separation technology, applied in water/sewage treatment equipment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the separation of liquid and solid without a stable and mature treatment equipment, and the treatment cost is high , fewer applications, etc., to achieve the effect of reducing the area used by equipment and reducing the number of processing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

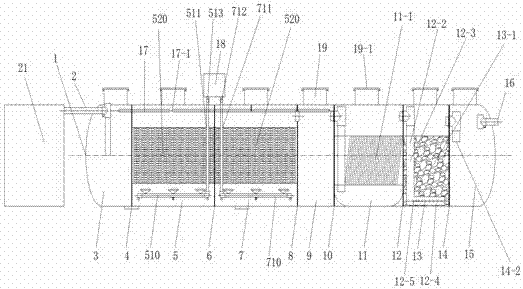

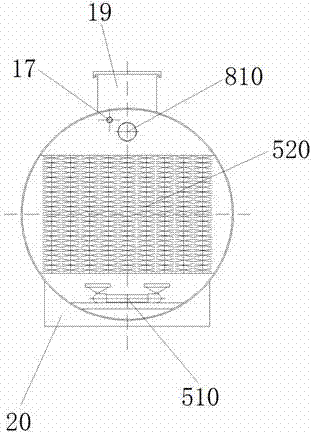

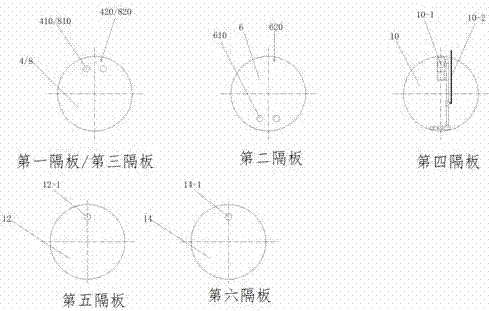

[0023] Please refer to Figure 1-Figure 4 , figure 1 A schematic diagram of the overall structure of the integrated sewage treatment liquid-solid separation equipment is provided for the present invention; figure 2 Provide the sectional view of aerobic aeration packing tank for the present invention; image 3 Provide the structural representation of each separator for the present invention; Figure 4 A schematic structural diagram of the aeration device is provided for the present invention.

[0024] Specifically, the integrated sewage treatment liquid-solid separation equipment provided in this embodiment includes: a tank body 1, a water inlet 2, a first sedimentation tank 3, a first partition 4, an aerobic aeration filler tank 5, a second partition Plate 6, anoxic aeration filler tank 7, third separator 8, second sedimentation tank 9, fourth separator 10, inclined tube filler sedimentation tank 11, fifth separator 12, quartz sand filter tank 13, sixth Partition 14, thir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com