Waste gas treatment device in coal tar processing process

A waste gas treatment device and processing technology, which is applied in the field of absorption towers, can solve the problems of high cost, large area, and waste of funds, and achieve the effects of reducing cost and capital investment, reducing the number of processing equipment, and reducing the area occupied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

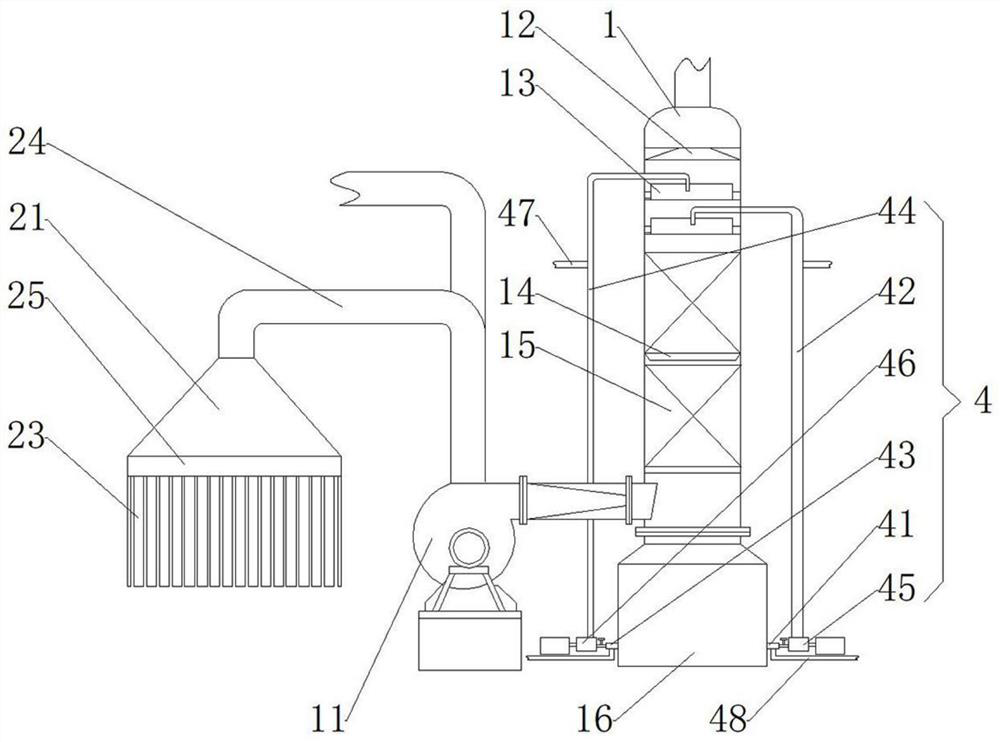

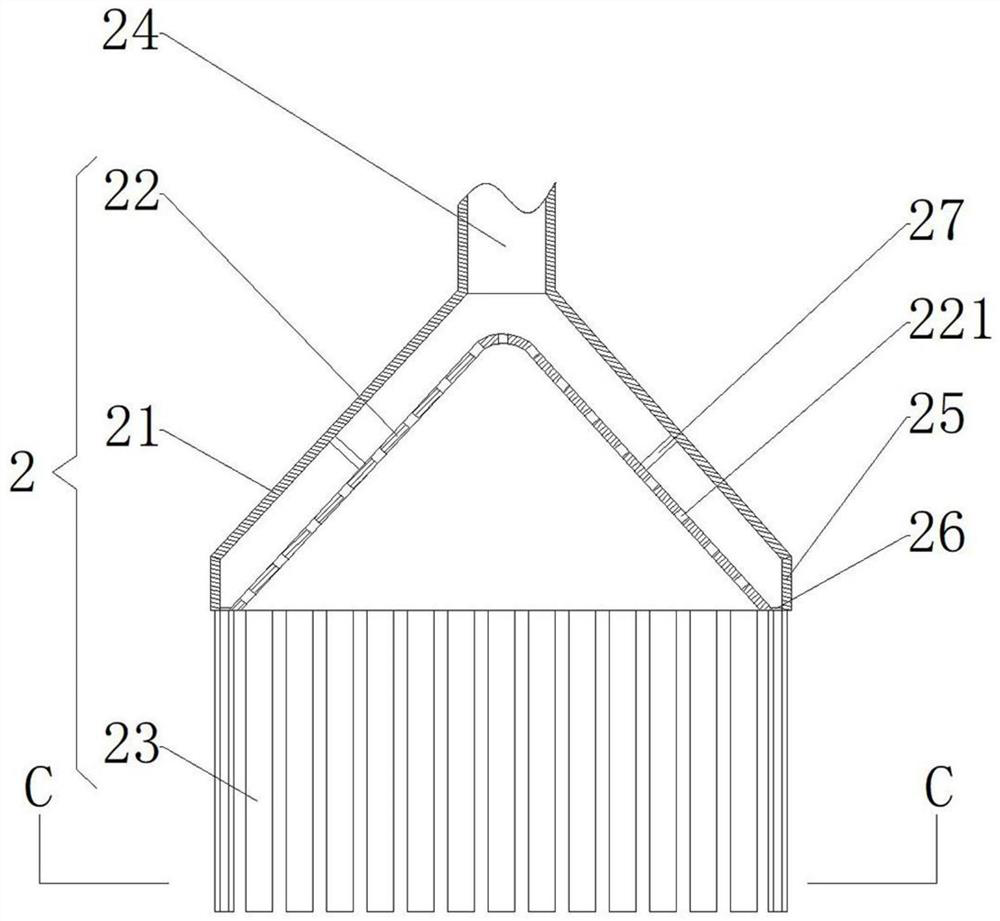

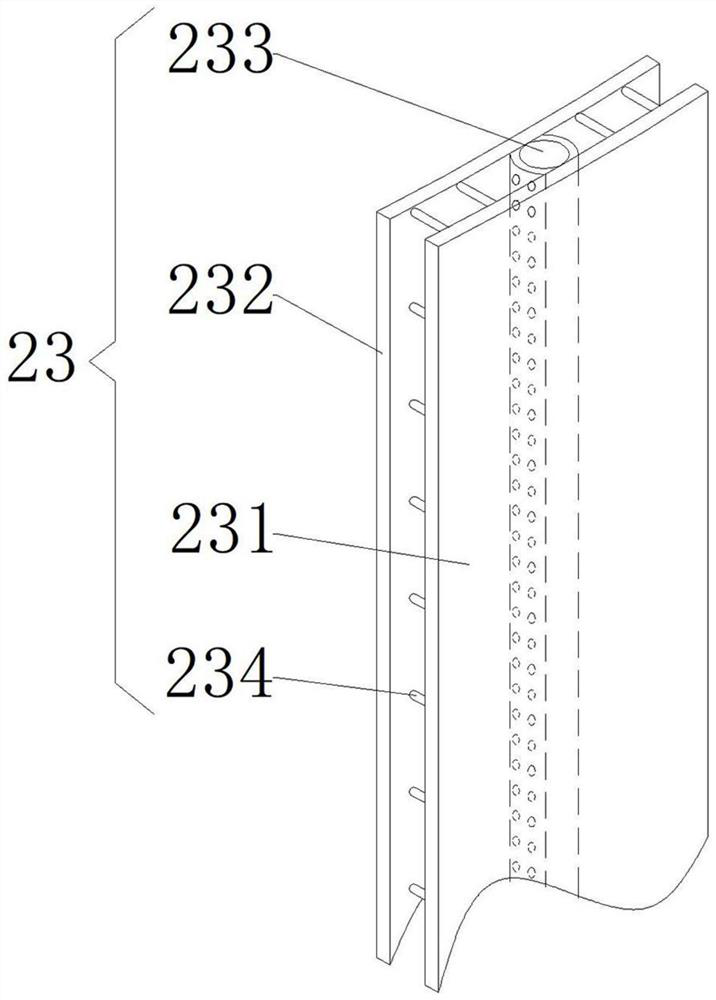

[0034] Such as Figure 1 to Figure 8 As shown, a waste gas treatment device in the process of coal tar processing includes an absorption tower body 1, the left lower part of the absorption tower body 1 is provided with a fan 11, and the fan 11 communicates with the air inlet of the absorption tower body 1, The top of the absorption tower body 1 is connected with an exhaust pipe upwards, and a demister 12 is installed in the top of the absorption tower body 1, and two liquid distributors 13 are arranged below the demister 12, and the middle part of the inner wall of the absorption tower body 1 is installed. There is a redistributor 14, and the redistributor 14 is located below the two liquid distributors 13, and the inside of the absorption tower body 1 is provided with two packing layers 15, and the two packing layers 15 are respectively located belo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com