Mine bolt hole internal reamer

An anchor hole and hole reamer technology, applied in drilling equipment and methods, earthwork drilling, drill bits, etc., can solve the problems of difficult tool recovery, unstable hole reaming, poor hole reaming performance, etc. Stable, safe and efficient mining and support, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

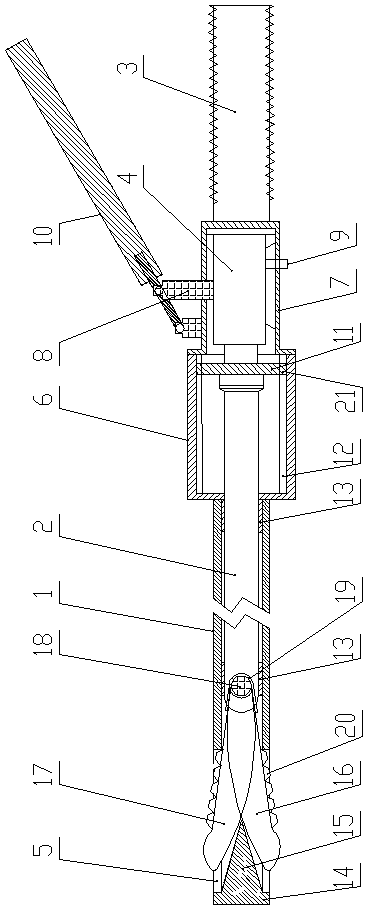

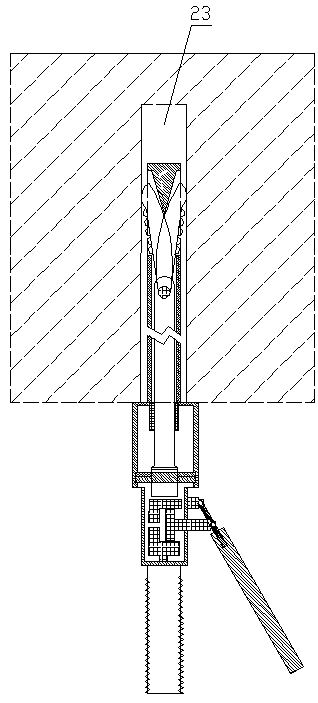

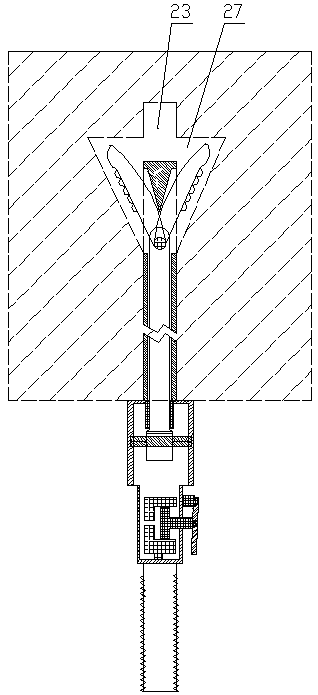

[0016] like Figure 1-Figure 3 As shown, the internal reamer of the mine bolt hole of the present invention includes a reaming tool, a casing 1, a push-pull rod 2, a drilling rig connecting shaft 3 and a manual hydraulic jack 4, and the push-pull rod 2 is coaxially arranged on the casing 1 Inside, the casing 1 and the push-pull rod 2 are arranged horizontally along the front-to-back direction, the rear end of the reaming tool is connected to the front end of the push-pull rod 2, and the center of the front side of the casing 1 is symmetrically provided with two long lengths that are all set along the axial direction of the casing 1. Hole 5, the front end of casing 1 is provided with a top pressure structure for driving the reaming tool to extend radially out of long hole 5, and the rear end of casing 1 is coaxially fixedly connected with a guide cylinder 6 with an inner diameter larger than casing 1. The rear end of the cylinder 6 is fixedly connected with the installation cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com