A labor-saving socket wrench

A socket wrench and socket technology, which is applied in the direction of wrenches, manufacturing tools, screwdrivers, etc., can solve the problems that it is difficult to quickly unscrew high-torque bolts or nuts, and achieve the effects of improving disassembly efficiency, convenient use, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

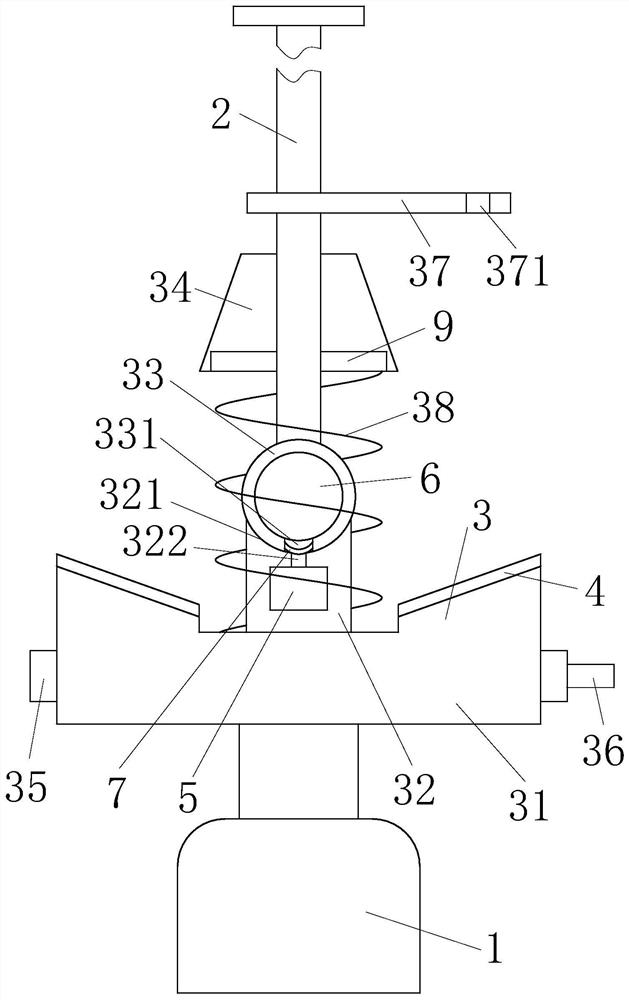

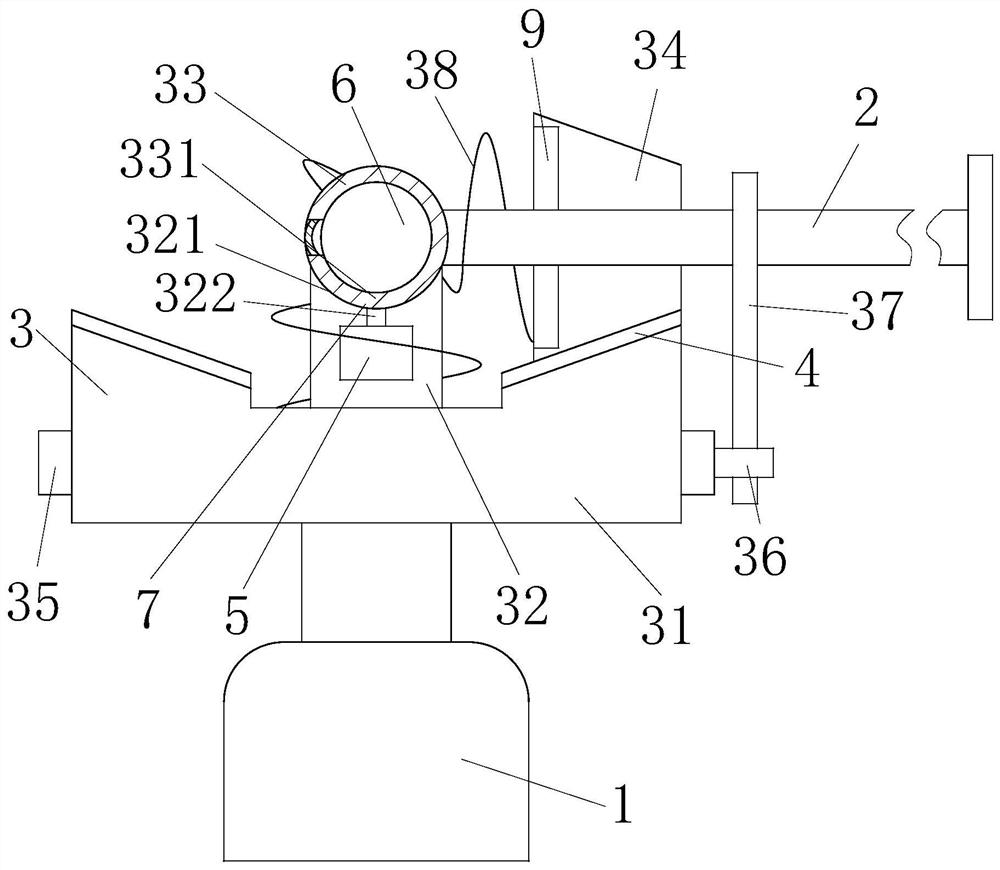

[0020] use Figure 1-Figure 5 A labor-saving socket wrench according to an embodiment of the present invention will be described as follows.

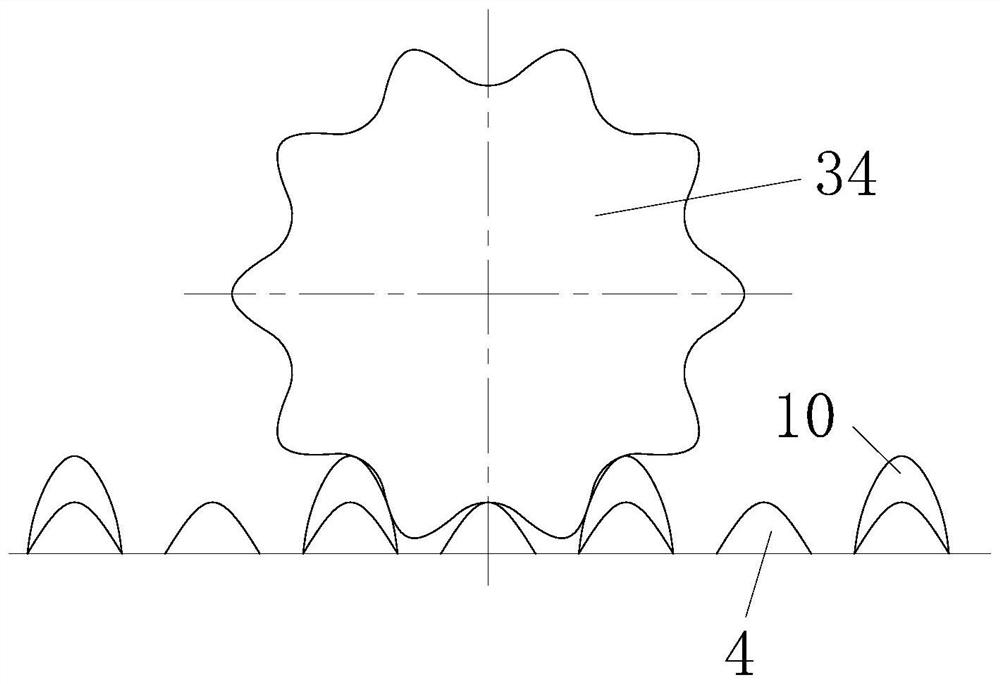

[0021] Such as Figure 1-Figure 4 As shown, a labor-saving socket wrench according to the present invention includes a socket 1 and a handle 2, and also includes a bending unit 3, which is used to bend the handle 2 in any direction relative to the socket 1 , so that the nut or bolt is loosened by using the bending of the handle 2 and the sleeve 1 to generate a large torque. The bending unit 3 includes a fixed block 31, a connecting block 32, a rotating ball 33, a bevel gear 34, a swivel 35, a limiter Position pin 36, limit plate 37 and spring 38, sleeve 1 is installed at the lower end of described fixed block 31, and the upper surface of fixed block 31 is provided with a circular truncated groove with large upper end opening and small lower end opening, and fixed block 31 is in the circular truncated groove. On the side wall of the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com