Installation and construction method of mine bolt for roadway support

A roadway support and construction method technology, which is applied to the installation of bolts, mining equipment, earthwork drilling and mining, etc., can solve the problems of poor reaming performance, unstable reaming, difficult tool recovery, etc., and achieve stable reaming performance, Safe and efficient mining and support, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

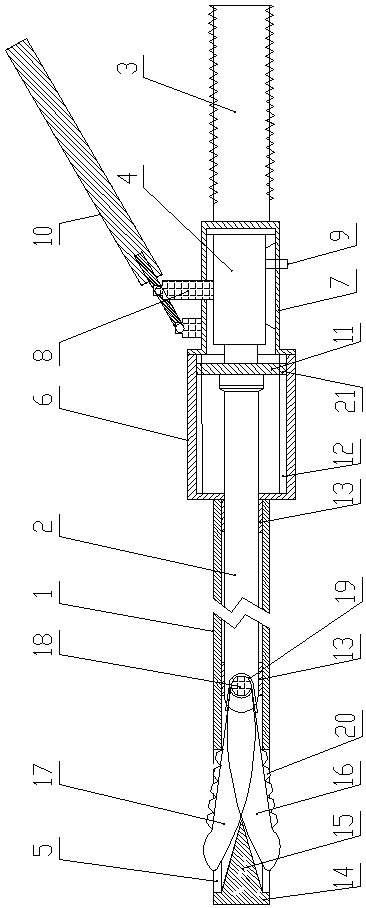

[0025] Such as Figure 1-Figure 3 Shown, roadway support of the present invention is used mine bolt installation and construction method, comprises the following steps:

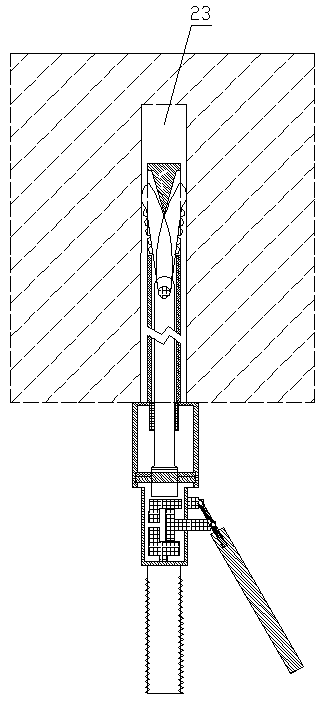

[0026] (1) Use a drilling rig to connect ordinary drill pipes to drill the bolt hole 23 after demarcating the position on the roadway wall;

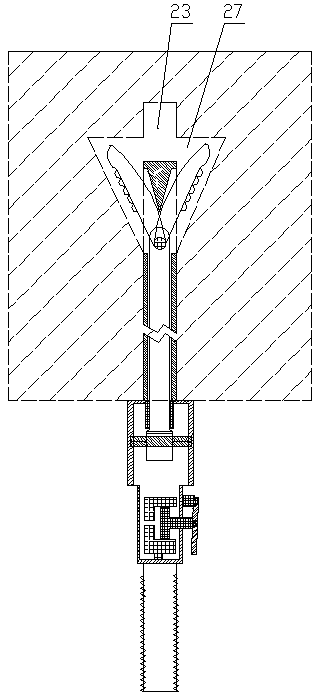

[0027] (2) Remove the ordinary drill pipe, replace the reaming drill pipe and connect it with the drilling rig, push the reaming drill pipe into the anchor hole 23 and carry out the reaming operation on the bottom of the anchor hole 23. After the reaming operation is completed, Exit the reaming drill pipe;

[0028] (3), clean up the coal cuttings and cuttings in the bolt hole 23;

[0029] (4) Insert the anchor rod into the anchor rod hole 23, and inject the anchoring agent 24 into the anchor rod hole 23;

[0030] (5) After the anchoring agent 24 is solidified, put a backing plate on the anchor rod and screw on a nut to press the backing plate against the roadway wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com