A torque transmission device connecting an engine turbine and a compressor rotor

A compressor rotor, turbine rotor technology, applied in mechanical equipment, rigid shaft couplings, couplings, etc., can solve the problems of complex assembly, high cost, high machining accuracy of parts, and complex assembly and decomposition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

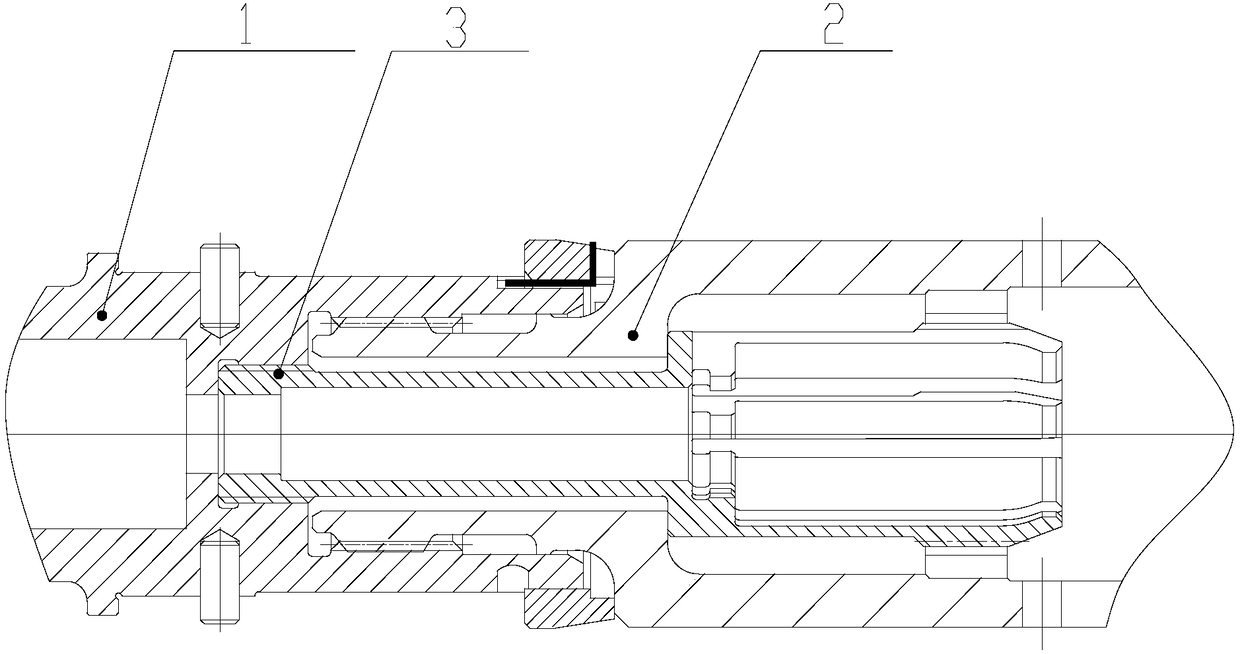

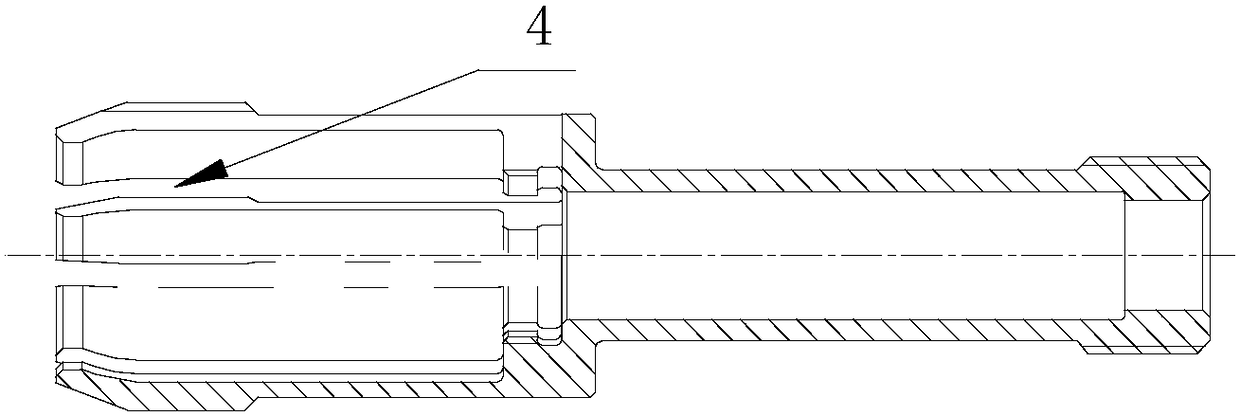

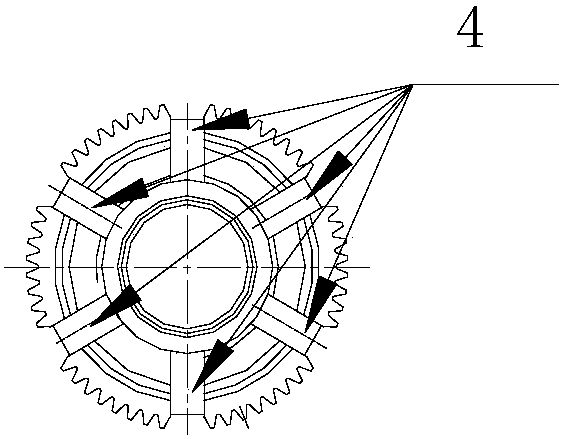

[0010] As shown in the figure, the torque transmission device connecting the engine turbine and the compressor rotor includes a compressor rotor 1, a turbine rotor 2, and a connecting screw 3. The compressor rotor 1 is provided with internal splines, and the turbine rotor 2 is provided with external splines. And cooperate with the internal spline of the compressor rotor 1, one end of the connecting screw 3 is provided with a thread and installed in the inner cavity of the compressor rotor 1, and the other end is provided with a step and is stuck on the step of the inner cavity of the turbine rotor 2, said The stepped position of the connecting screw 3 is also provided with an external spline, and cooperates with the internal spline provided on the inner cavity of the turbine rotor 2; the external spline part on the connecting screw 3 is a hollow structure, and an axial opening Groove 4, described groove 4 is uniformly distributed 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com