Wear ring easy to mount and used for reducing leakage

An easy-to-install, mouth-ring technology, applied in the field of centrifugal pumps, can solve the problems of not completely preventing backflow, volume loss, disturbing the mainstream, etc., to achieve a good sealing effect and prevent backflow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with specific embodiments.

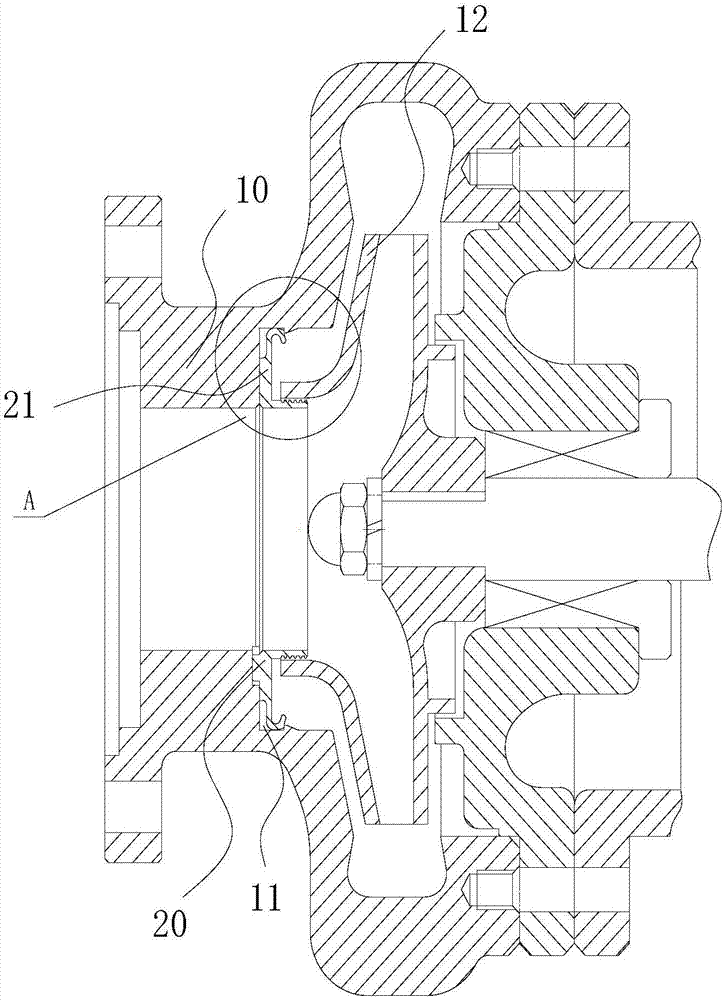

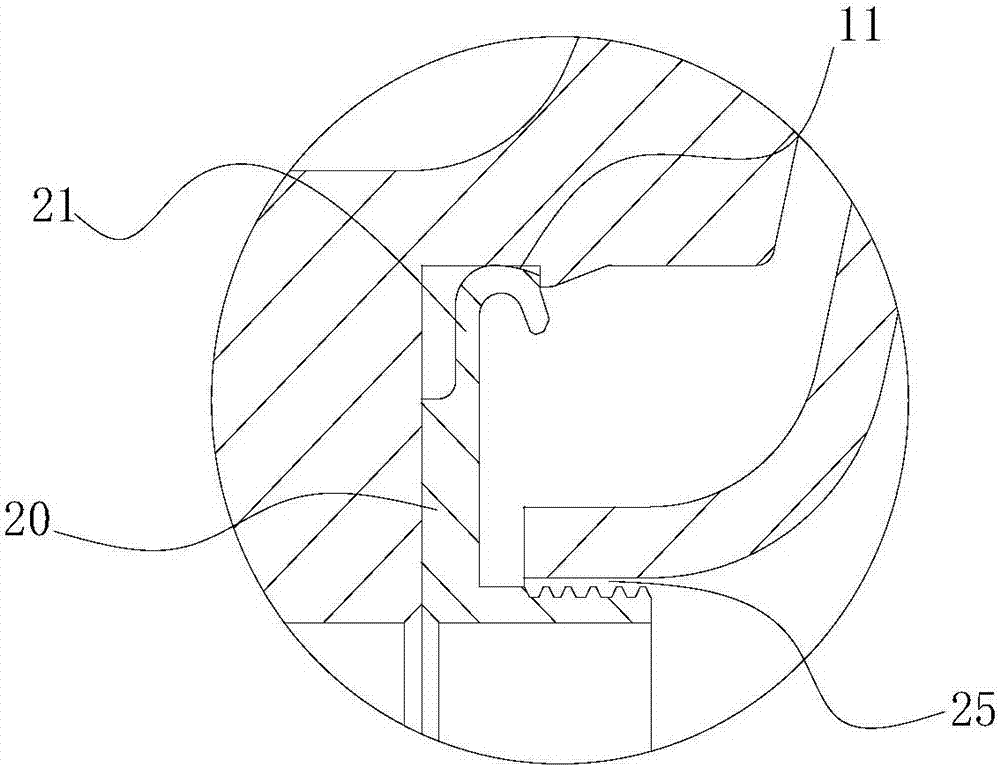

[0029] Such as figure 1 , 2 , 3 and 4, an easy-to-install mouth ring for reducing leakage, the mouth ring 20 is provided with an elastic buckle 21, and the pump body of the centrifugal pump 10 is provided with a slot 11 that matches the elastic buckle 21, The elastic buckle 21 forms an interference connection with the slot 11 , and the diameter of the slot 11 is 0.1-1 mm smaller than that of the mouth ring 20 . The mouth ring 20 can not use screws, but rely on the interference connection between the elastic buckle 21 and the slot 11 and the elastic deformation of the elastic buckle 21 to achieve the function of fixing the mouth ring 20;

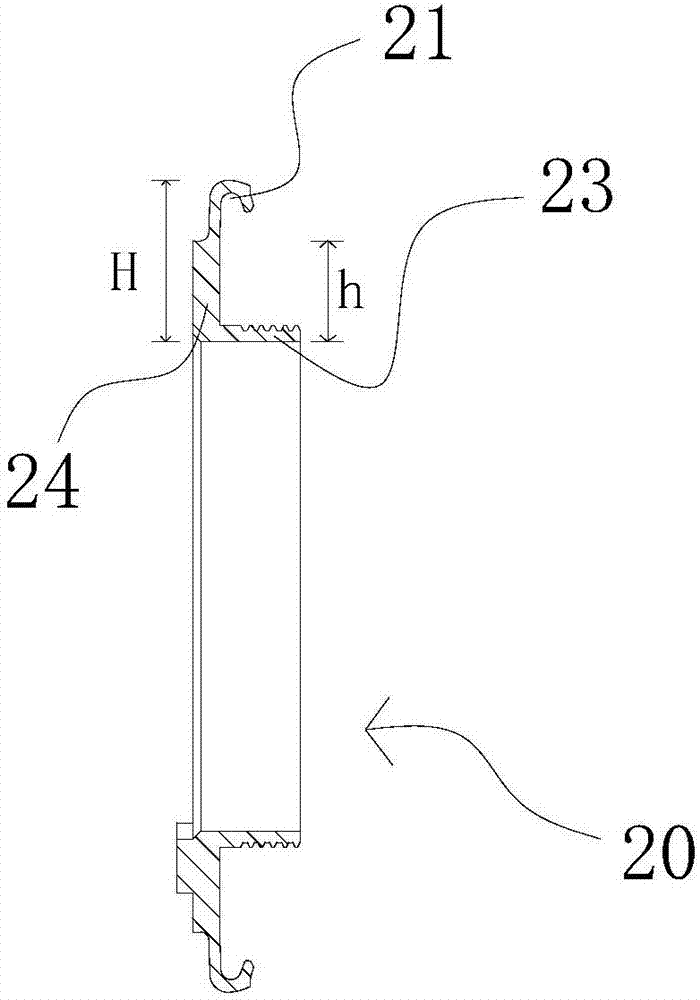

[0030] To further optimize the above embodiment, the length from the inner wall of the mouth ring 20 to the top of the elastic buckle is H, the length from the inner wall of the mouth ring 20 to the root of the elastic buckle is h, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com